A kind of synthetic method of tebuthiauron

A technology of terbufenthiuron and a synthesis method, applied in the field of organic synthesis, can solve the problems of high safety risk, difficult industrialized operation, high toxicity of reaction raw materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

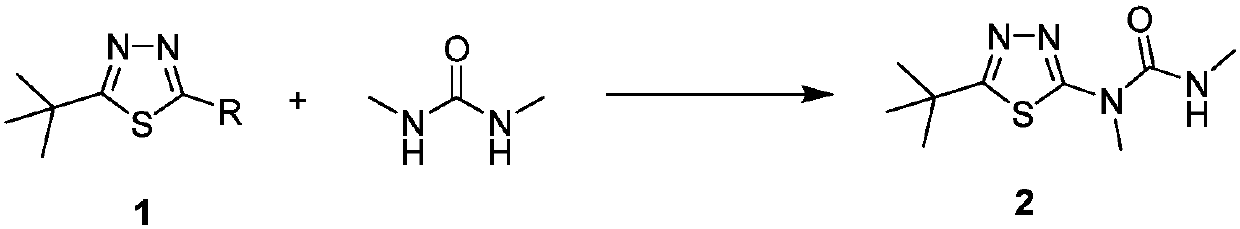

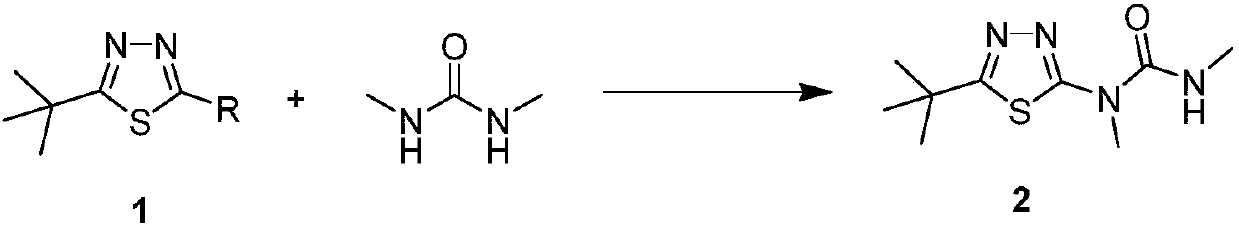

Method used

Image

Examples

Embodiment 1

[0025] Add 200g of toluene, 100g (0.54mol) of 5-tert-butyl-2-chloro-1,3,4-thiadiazole, 52.6g (0.59mol, 1.1eq) of 1,3-dimethylurea into the reaction flask , stir evenly, heat up to 60°C, add dropwise 30% aqueous sodium hydroxide solution 86g (0.65mol, 1.2eq), continue to insulate for 5 hours after the dropwise addition, complete the reaction, separate layers, continue to wash the toluene phase twice, and remove the solvent. About 150g of toluene was extracted, cooled to 0°C and left to stand for 6 hours, the product precipitated, and 120g of white solid was obtained by suction filtration, which was verified as Tebuthiauron by mass spectrometry and hydrogen spectrometry, and its purity was 97% by HPLC, and the yield was 94.4 %.

Embodiment 2

[0027] Add 300g of chlorobenzene, 100g (0.54mol) of 5-tert-butyl-2-chloro-1,3,4-thiadiazole, 55g (0.62mol, 1.15eq) of 1,3-dimethylurea into the reaction flask , Potassium Carbonate 90g (0.65mol, 1.2eq), stir evenly, slowly heat up to 50°C, keep warm for 3 hours, after the reaction is complete, add water and stir to separate layers, continue to wash the chlorobenzene phase twice with water, and extract about 250g of chlorobenzene , cooled to 10°C and left to stand for 4 hours, the product precipitated out, and 115g of white solid was obtained by suction filtration, which was verified as Tebuthiauron by mass spectrometry and hydrogen spectrometry, and its purity was 96% by HPLC detection, and the yield was 90.0%.

Embodiment 3

[0029] Add 500 g of dichloromethane, 100 g (0.54 mol) of 5-tert-butyl-2-chloro-1,3,4-thiadiazole, 57.4 g (0.64 mol, 1.2 eq), stir evenly, slowly raise the temperature to 40°C, add 77g (0.77mol, 1.4eq) of triethylamine dropwise, and keep warm for 8 hours. , about 450g of dichloromethane was released, cooled to 20°C and left to stand for 4 hours, the product was precipitated, and 113g of white solid was obtained by suction filtration, which was verified as Tebuthiauron by mass spectrometry and hydrogen spectrometry, and its purity was 96% as detected by HPLC. Yield 88.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com