Preparation method of high-purity and low-chroma gemfibrozil

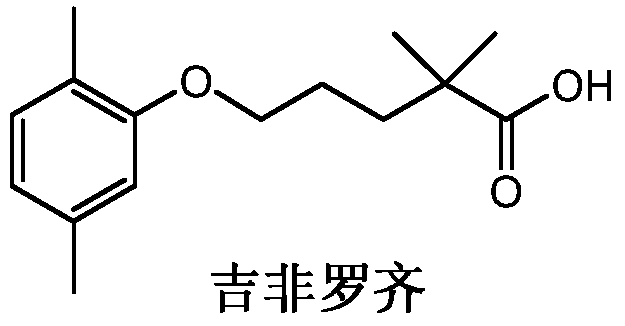

A technology of gemfibrozil and gemfibrozil isobutyl ester, applied in the field of medicinal chemistry, can solve the problems of gemfibrozil unqualified, easy to deteriorate and easy to change color after long-term storage, and achieve pure white color and high quality Requirements, the effect of low chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

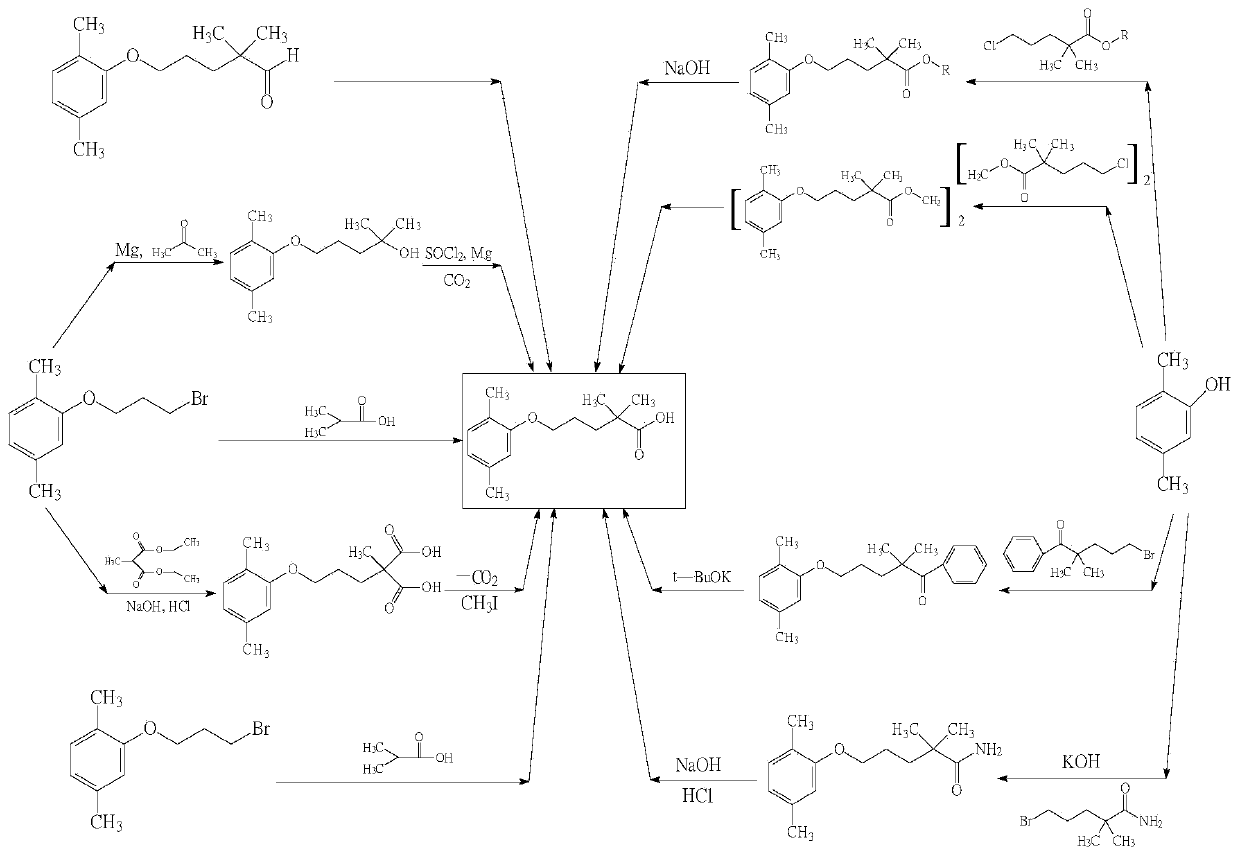

Method used

Image

Examples

Embodiment 1

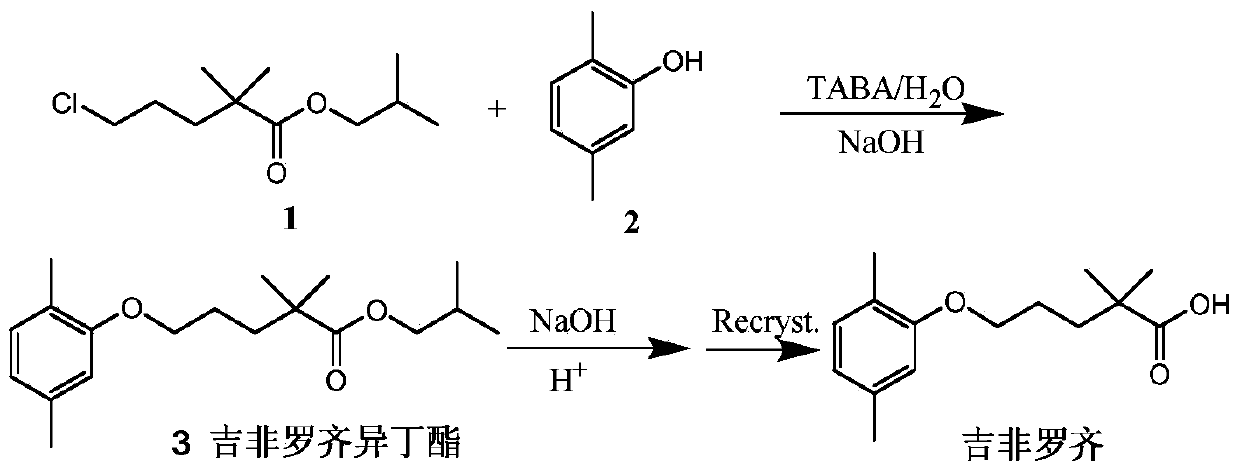

[0035] Embodiment 1, a kind of preparation method of high-purity, low chroma gemfibrozil, carries out following steps successively:

[0036] 1), in a 1000ml reaction bottle, put 180ml of water, 182 grams of 5-chloro-2,2-dimethylpentanoic acid isobutyl ester (0.82mol, 107 grams of 2,5-xylenol (0.87mol), 130 grams (3.2mol) of sodium hydroxide, 10 grams of tetrabutylammonium bromide, heated and refluxed for 10 hours. After the reaction solution was cooled to room temperature, the static layering was carried out for 30 minutes, and the upper organic layer separated was washed with 10% (mass % ) sodium hydroxide solution (about 30ml * 3 times), the condensation product crude gefibutyl ester was obtained, ready for distillation. Through liquid phase detection, the content of 2,5-xylenol was 0.021%.

[0037] Remarks: Washing with 10% sodium hydroxide solution can remove as much free 2,5-xylenol as possible in the organic layer.

[0038] 2), the above-mentioned gefibutyl ester crude ...

Embodiment 2-1

[0042] Embodiment 2-1, a kind of preparation method of high purity, low chroma gemfibrozil:

[0043] Step 1) is the same as step 1) of the embodiment;

[0044] 2) Add the above-mentioned crude product of gemfibroxan to a 500ml round bottom bottle, then add a small amount of saturated sodium carbonate solution, adjust the pH to 10.0-10.5, raise the temperature to an internal temperature of 190 degrees, and distill under reduced pressure to obtain gemfibrox The distilled product of isobutyl ester has a normalized liquid phase content of 99.87%, and a 2,5-xylenol content of 0.0004%.

[0045] Step 3) and step 4) are equal to step 3) and step 4) of Example 1; 182 grams of gefibrozil are finally obtained, the yield is 89%, the normalized content of the liquid phase is 99.93%, and the xylenol content is 0.0001 %, Chroma 1.6.

Embodiment 2-2~ Embodiment 2-4

[0046] Embodiment 2-2~embodiment 2-4, the saturated sodium carbonate solution in embodiment 2-1 is changed into respectively that mass concentration is 70% sodium hydroxide solution, mass concentration is 70% potassium hydroxide solution, saturated Potassium carbonate solution; the pH was also adjusted to 10.0-10.5, and the rest of the content was equal to that of Example 2-1. The comparison of the obtained results is as described in Table 1 below.

[0047] Table 1

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com