Two-stage treatment method for offshore platform production wastewater

A technology for sewage production and treatment process, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. and other problems, to achieve the effect of high performance, short backwashing time and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

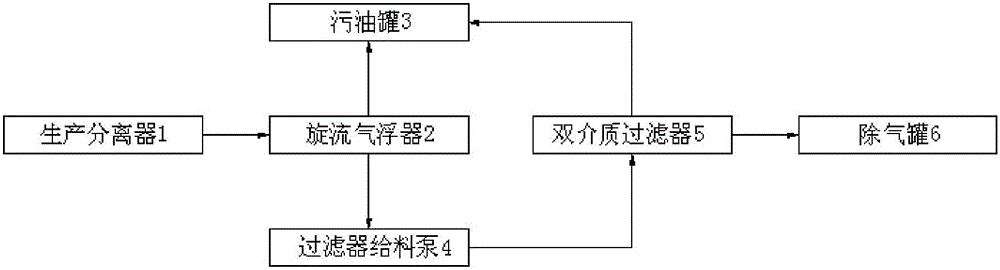

[0028] A two-stage treatment process for production sewage, comprising the following steps:

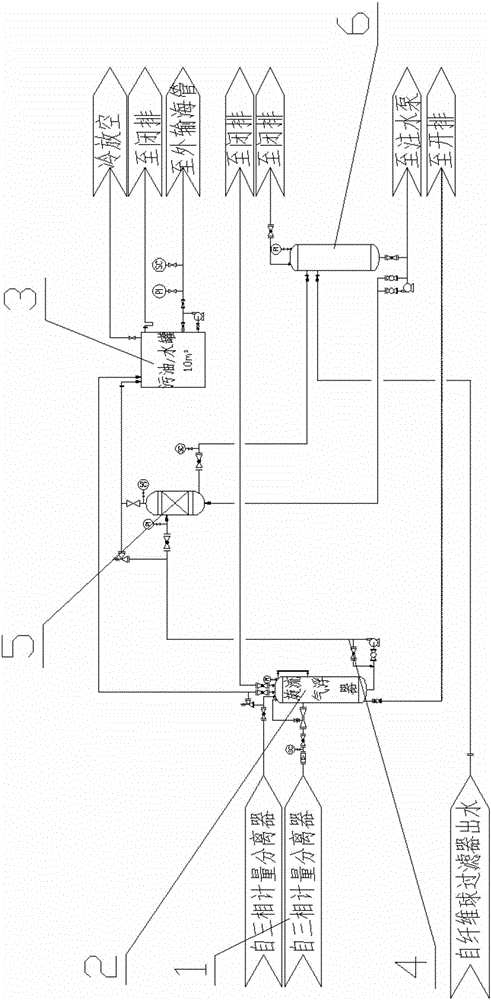

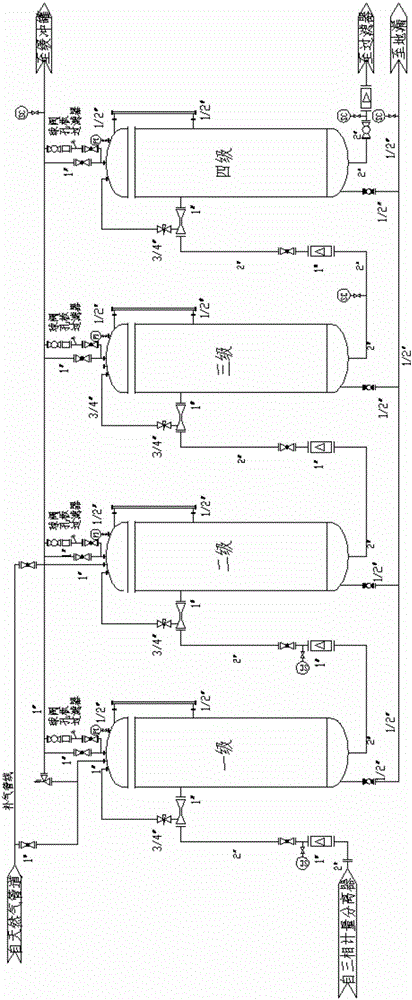

[0029] (1) Separating the 1400-1750kPaG production sewage from the production separator 1 containing 700-1000ppm of oil, depressurizing it to 1000kPaG through the air flotation inlet ejector, and entering the cyclone air flotation device 2 for separation treatment; the cyclone air flotation device 2 It is a skid-mounted structure, including four-stage cyclone air flotation device 2, and the production sewage enters the first-stage cyclone air flotation with an operating pressure of 1000kPaG, the second-stage cyclone air flotation with an operating pressure of 650kPaG, and the third-stage cyclone air flotation with an operating pressure of 350kPaG , and four-stage cyclone air flotation with an operating pressure of 50kPaG;

[0030] (2) The upper part of the water surface in the tank of the cyclone air flotation device 2 will merge into a continuous layer of oil and air bubbles and scum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com