Built-in Incense Forming Mold and Incense Forming Method of Incense Stove

A built-in, incense-forming technology, applied in the direction of gasification substances, etc., can solve the problem of small smoke and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

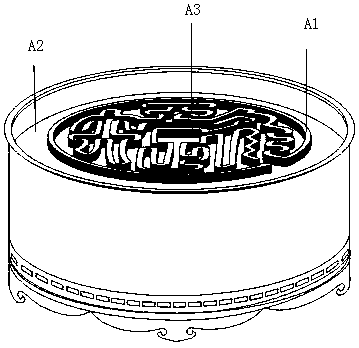

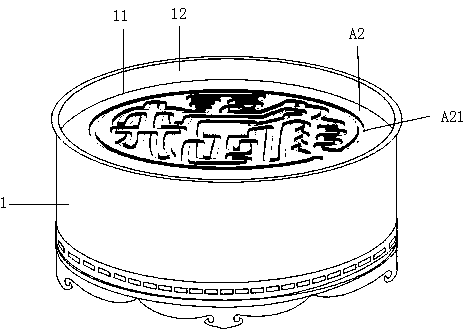

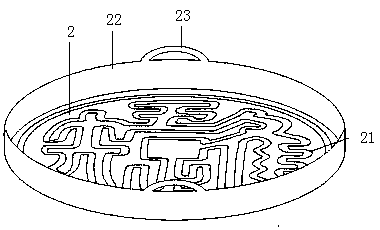

[0024] see Figure 2-4 , which is a built-in incense burner mold of the present invention. As shown in the figure: it includes a base 1, an incense plate 2 and a punch 3; the base 1 has a platform 11 on which the ash layer A2 is laid; the incense plate 2 has a hollow incense groove 21; the punch 3 There is a shaped platform 31 whose shape and position correspond to the incense groove 21; the height of the shaped platform 31 is greater than or equal to the thickness of the incense plate 2.

[0025] As a preferred manner, the edge of the platform 11 of the base 1 has a blocking wall 12 extending upwards, which can prevent incense ash and incense powder from overflowing.

[0026] As a preferred manner, the edge of the incense-shaped groove 21 has a blocking wall 22 extending upwards, which can prevent incense ash and incense powder from overflowing.

[0027] As a prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com