Electrostatic Force Rebalance Pendulum Silicon Micro Accelerometer Sensitive Structure and Manufacturing Method

An accelerometer and sensitive structure technology, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, measuring devices, etc., can solve the problem that the three-layer microstructure manufacturing process cannot be completely symmetrical, the influence of the symmetry of the upper and lower gaps, and the temperature characteristics of the instrument Poor and other problems, to improve the zero drift problem, reduce process costs, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

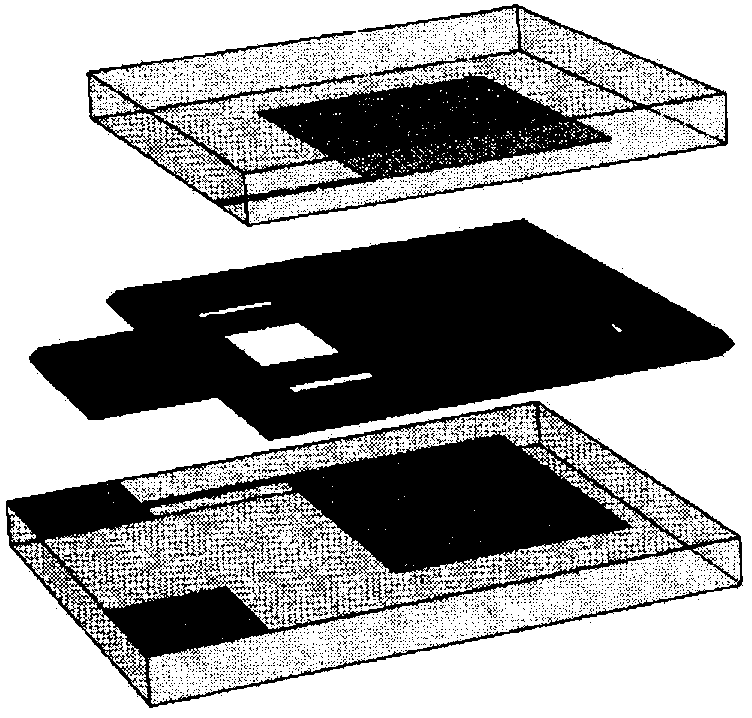

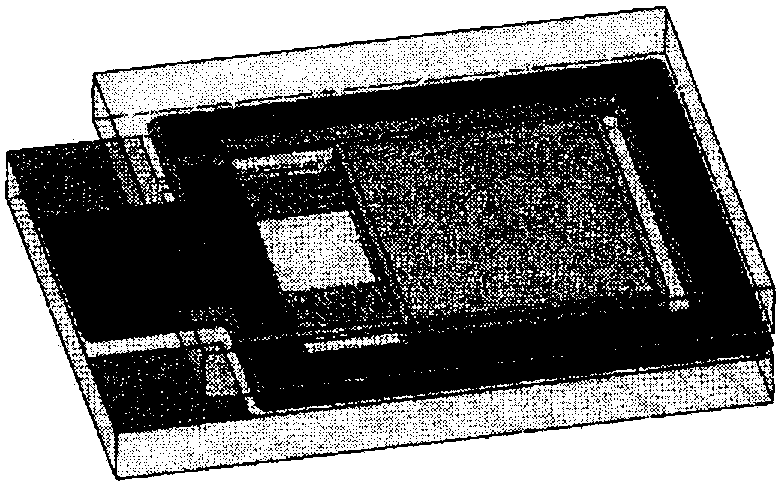

[0043] Such as Image 6 As shown, the structure of the present invention is that the upper and lower glass pole plates 1, 2, the middle is a sensitive mass 3 of monocrystalline silicon pendulum structure, and the three are connected together by bonding to support the sensitive mass of monocrystalline silicon. The double flexible beams 4 are arranged opposite to the electrode lead wires 5 .

[0044] In order to further confirm the effect of the present invention, the prior art is compared with the present invention here.

[0045] In the prior art, the microstructure of the silicon micro-accelerometer has a large deformation when the ambient temperature changes greatly, resulting in poor temperature characteristics of the instrument, which is characterized by a large temperature coefficient of 0.5mg / °C and poor temperature repeatability. Due to the asymmetry of the three-layer structure of the silicon micro accelerometer head, the temperature coefficient is brought, such as i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com