Optical fiber recoating device

A covering device and optical fiber technology, applied to the surface coating liquid device, optics, light guide, etc., can solve the problems of wasting resin, covering, resin bubbles, etc., and achieve effective and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

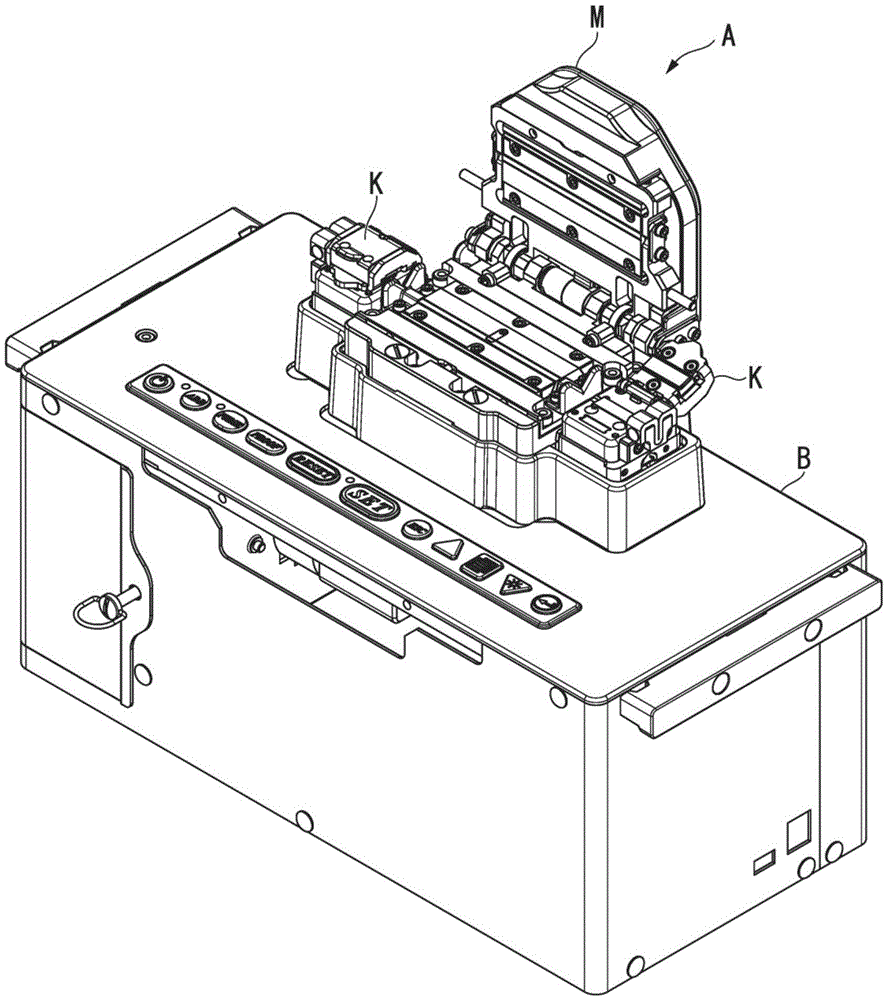

[0021] The optical fiber recoating device A of the present embodiment is a device for recoating the portion after the optical fiber-type optical component is manufactured by removing the coating (intermediate coating) of an arbitrary intermediate portion of the optical fiber. In addition, in the optical fiber recovered by the above-mentioned optical fiber recovering device A, the covering part and the cover covering the outer peripheral side of the covering part are formed concentrically from the axis. In addition, the covering of the optical fiber is made of, for example, an ultraviolet curable resin such as urethane acrylate, epoxy acrylate, polybutadiene acrylate, silicone acrylate, polyester acrylate, or the like.

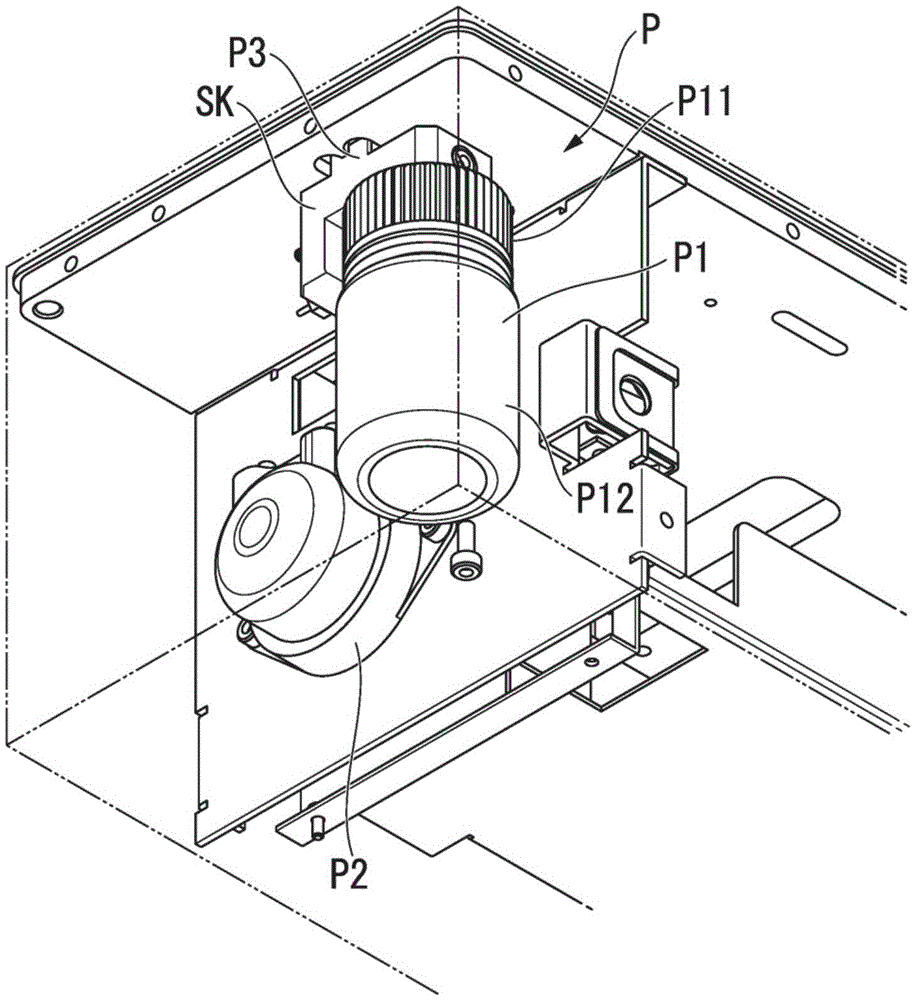

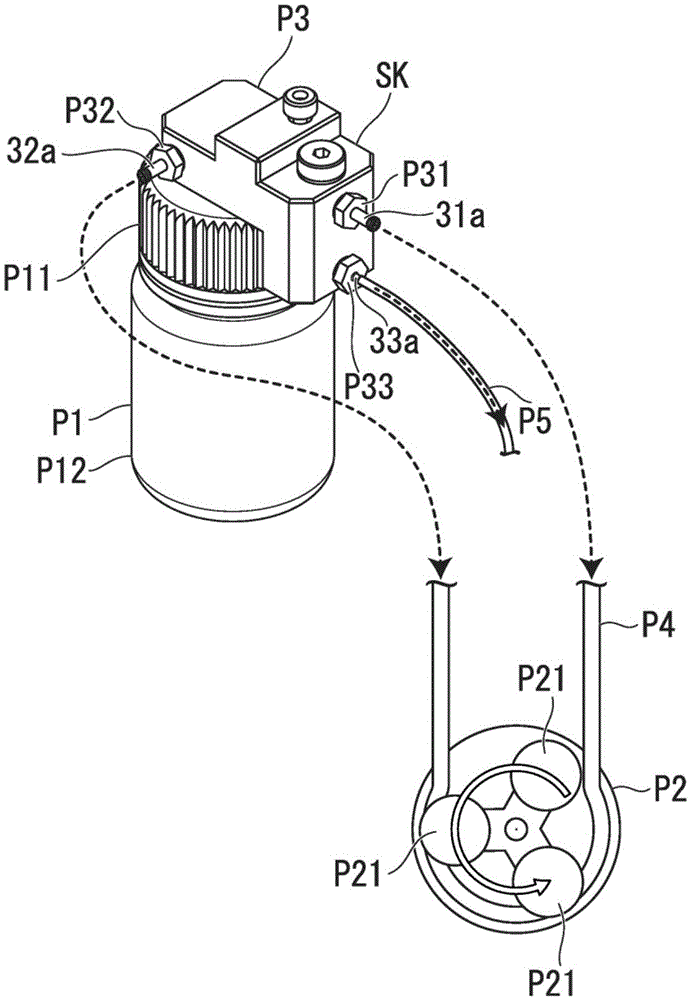

[0022] Such as figure 1 as well as figure 2 As shown, the above-mentioned optical fiber recoating device A includes an optical fiber covering part M, an optical fiber holding part K, a base B, and a resin supply part P.

[0023] Such as figure 1 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com