Device for inhibiting bubbles in printing ink

A suppression device and ink technology, applied in the direction of liquid degassing, foam dispersion/prevention, cleaning hollow objects, etc., can solve problems such as easy to generate a large number of bubbles and affect ink recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

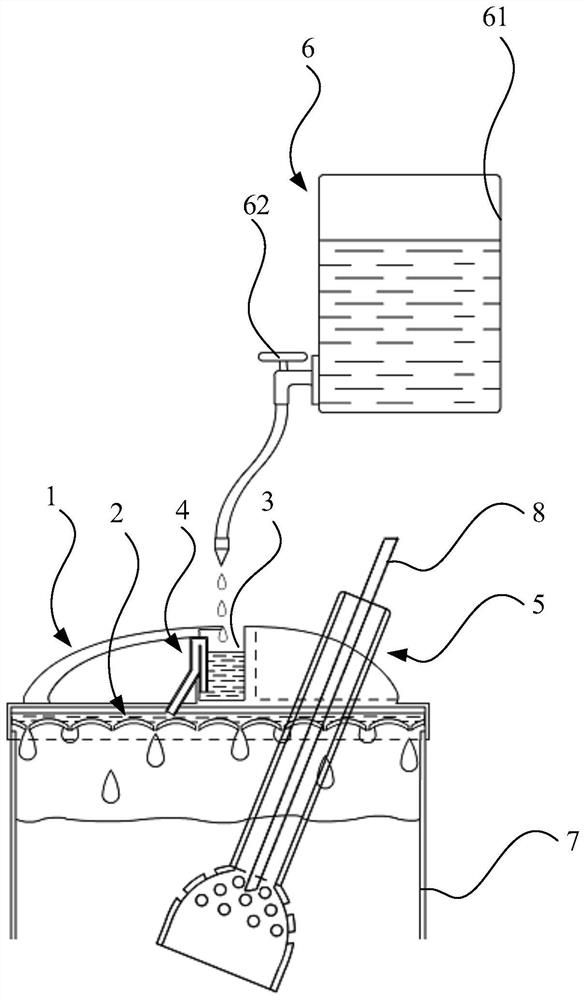

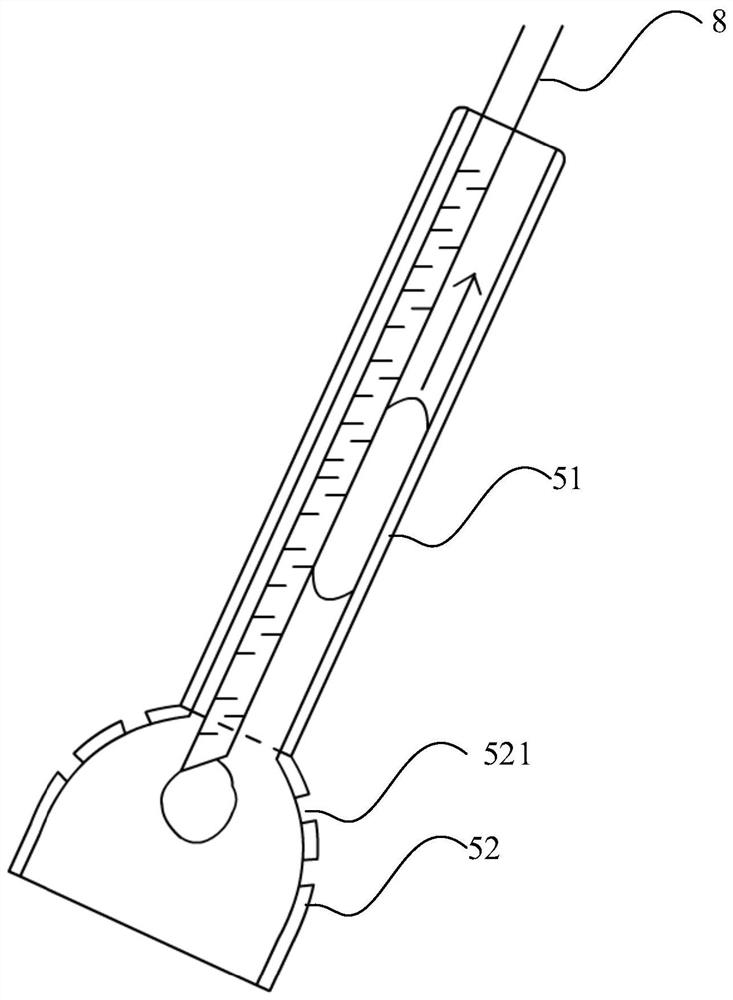

[0028] see figure 1 As shown, the embodiment of the present invention provides an ink bubble suppressing device, which is used to suppress the accumulation of bubbles in the ink on the ink liquid surface when the ink in the ink return pipe is recycled to the ink container, including: a cover plate 1, a distribution plate 2 and chamber 3.

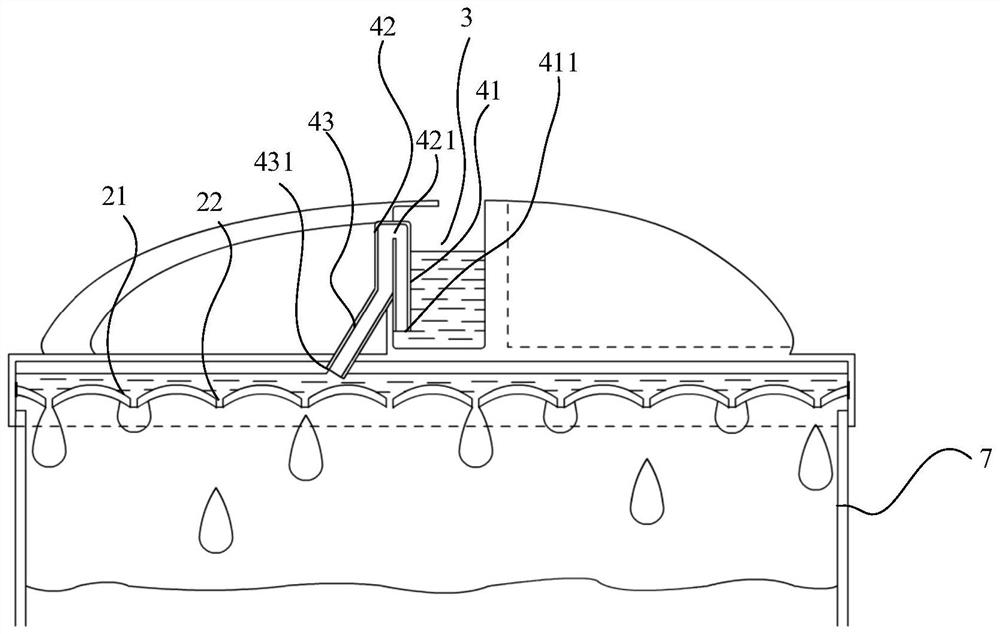

[0029] The cover plate 1 is installed on the ink container 7, and the spreading disc 2 is arranged on the side of the cover plate 1 facing the ink container, see figure 2 As shown, there are connected channels 21 distributed on the spreading plate 2, and a plurality of first through holes 22 are arranged in the channels 21.

[0030] The accommodation chamber 3 is fixed on the side of the cover plate 2 facing away from the ink container. The accommodation chamber 3 is used to contain the defoamer. The acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com