General AC motor driving detection system

A technology of AC motor and detection system, which is applied in the direction of AC motor control, motor generator test, control system, etc., can solve the problems of inaccurate operation stability, poor operation stability, and lack, etc., and achieve fast processing and calculation speed, Reliable performance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

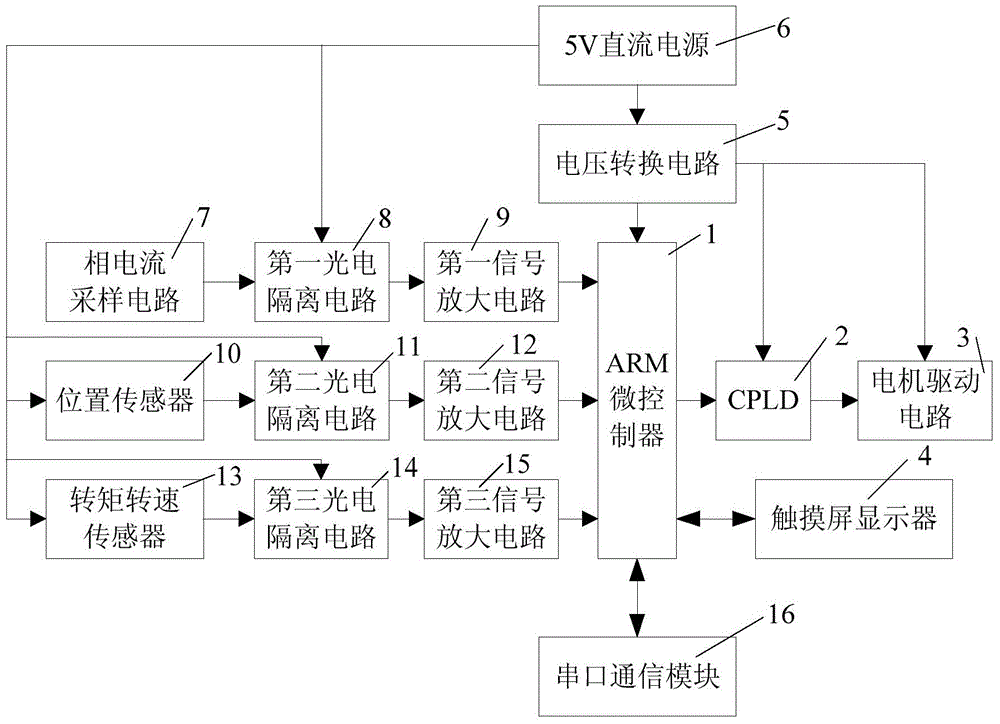

[0025] Such as figure 1 As shown, the present invention includes an ARM microcontroller 1, a power supply module, a touch screen display 4 connected with the ARM microcontroller 1 and used for setting monitoring data thresholds and display data, and connected with the ARM microcontroller 1 and used for data A serial port communication module 16 for communication, and a motor drive circuit 3 for driving the motor to run stably; the input terminal of the ARM microcontroller 1 is connected with a phase current acquisition module of the motor, a position information acquisition module for detecting the rotor position and The rotational speed torque information module that is used to detect rotor rotational speed torque; The output terminal of described ARM micro-controller 1 is connected with the CPLD2 that is used to send all kinds of data information that collects into driver drive motor; The motor drive circuit 3 The input terminal is connected with the CPLD2; the phase current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com