Data selection method for calculating blunt round radius of cutting edge

A technology of data selection and blunt circle radius, which is applied to measuring devices, instruments, optical devices, etc., can solve the problem that the calculation method of cutting edge blunt circle radius cannot reasonably select the data range of cutting edge blunt circle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

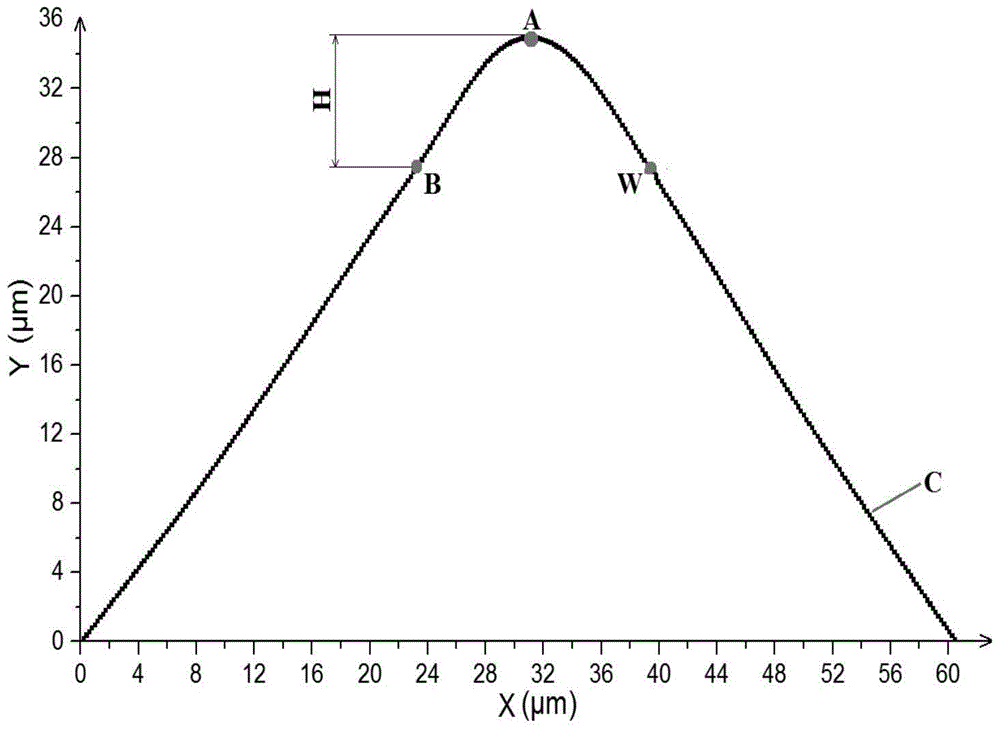

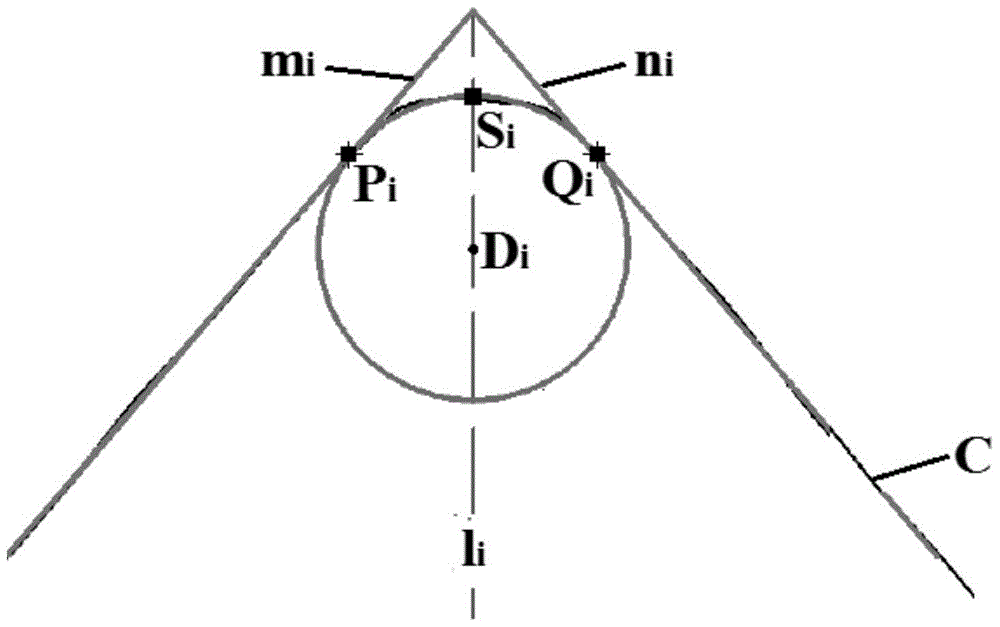

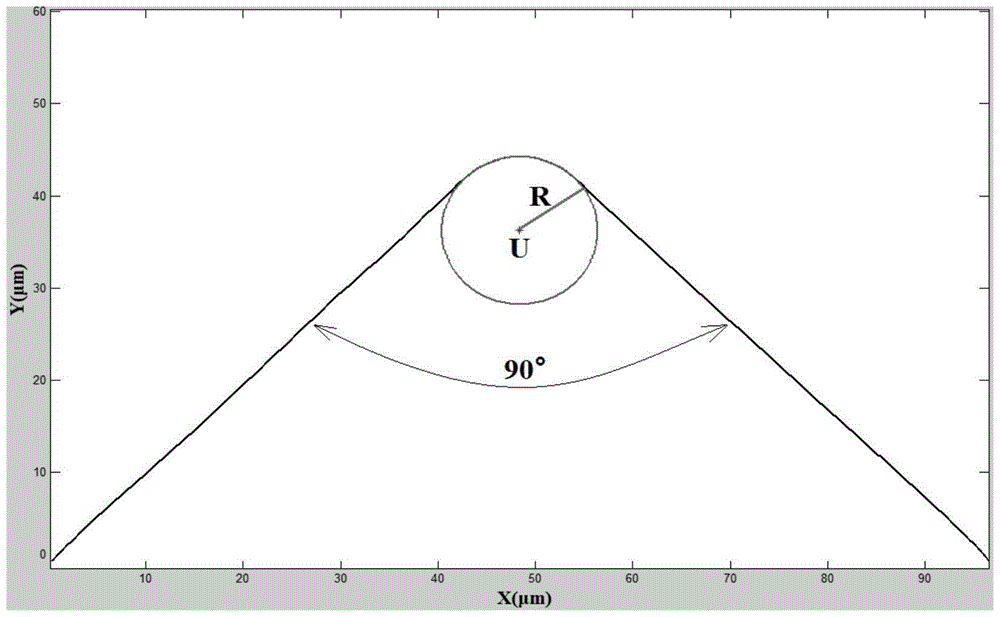

[0031] Taking a certain cutting edge of a double-vertex angle drill bit for drilling carbon fiber reinforced composite materials as the measurement and fitting calculation object, according to Figure 5 The operation process shown selects the data used for the calculation of the radius of the cutting edge blunt circle of the tool, based on which data is fitted to the blunt circle of the cutting edge and calculates the radius R of the blunt circle of the cutting edge of the tool. First, the ultra-depth-of-field microscope is used to observe the shape of the cutting edge of the tool by using the three-dimensional image synthesis function, and the contour of the cutting edge of the tool is intercepted by using the ultra-depth-of-field microscope software, and the data point C of the cutting edge profile of the tool is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com