Method for measuring wear of numerical control milling cutting tool based on shape copying

A technology for processing tools and tool wear, which is applied in the direction of manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems affecting the surface quality and dimensional accuracy of workpiece processing, increasing the cost and time of experiments, and increasing manufacturing costs, etc., to achieve The effect of reducing experiment cost and time, improving utilization rate and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

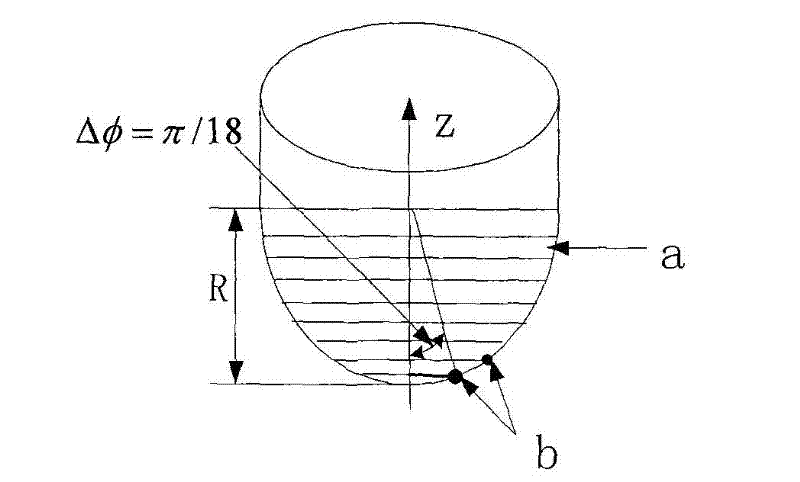

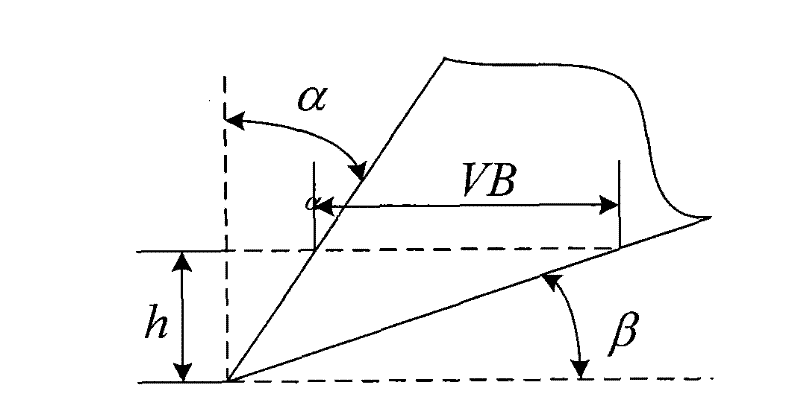

[0032] The specific implementation steps of the tool wear measurement method based on shape replication proposed by the present invention will be further described below.

[0033] (1) Experimental program design

[0034] According to the type of tool material and workpiece material, considering the number of tool edges, spindle speed, feed rate, cutting depth and cutting width parameters in machining, the experimental program of tool wear CNC milling was designed by orthogonal experiment method.

[0035] (2) Copy material preparation

[0036] According to the shape of the tool to be copied in the NC machining experiment plan and the number of processing experiments, prepare one or several blocks of finely processed copying materials. The above-mentioned copying materials are easy-to-process materials with negligible tool wear, and the shape is a cuboid. CNC machining experiments In the plan, add 8-12 cm to the maximum radius of the cutter as the thickness of the copy material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com