Blended yarn multifunctional fabric and making method thereof

A blended yarn, multifunctional technology, applied in the field of blended yarn multifunctional fabric and its preparation, can solve the problems of insufficient completeness and single function, and achieve improved compression resistance, excellent mechanical properties, good strength and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

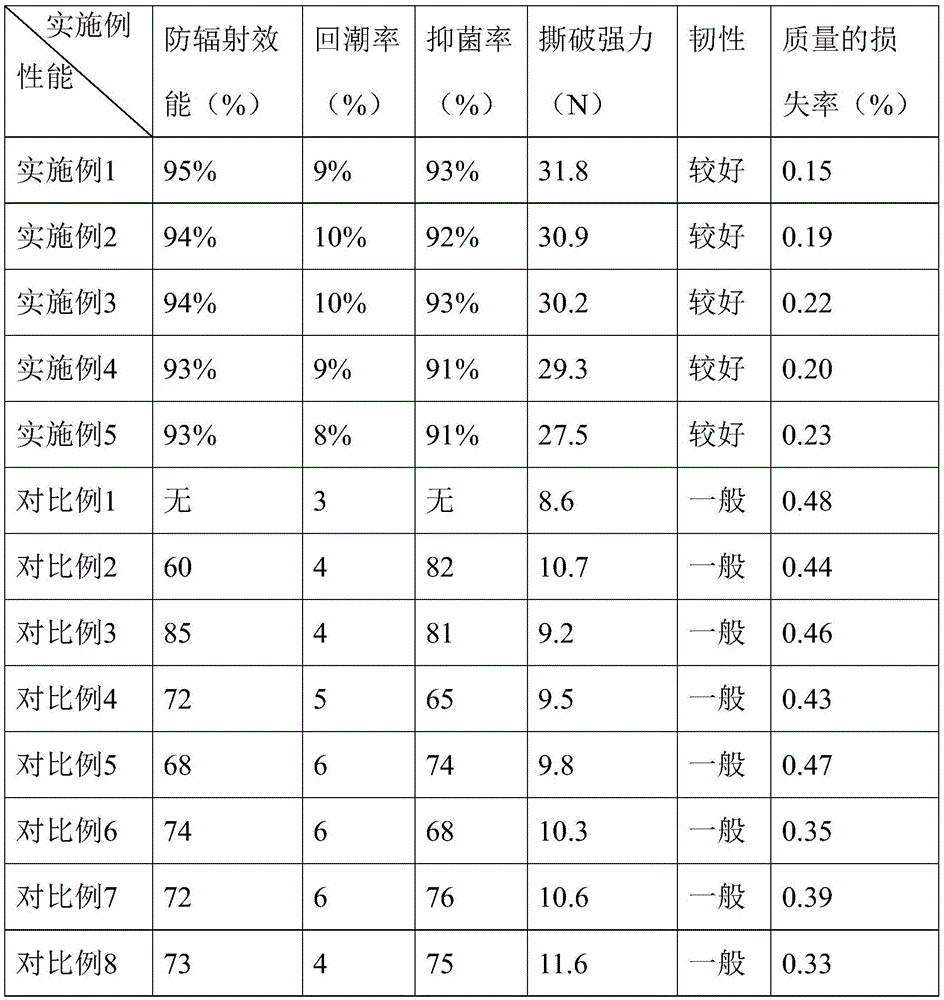

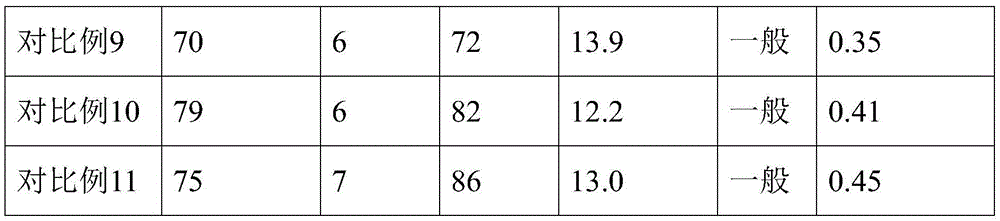

Examples

Embodiment 1

[0020] Warping yarn: bobbin, warping, coiling, warp head, sizing, coiling, doubling, weaving weaving; in the doubling process, stainless steel fiber, copper fiber and carbon fiber are gradually wrapped around the spandex yarn core Spun into warp blended yarn; the contents of stainless steel fiber, copper fiber, carbon fiber and spandex are 8%, 3%, 4% and 85% respectively;

[0021] Whole weft yarn: bobbin, warping, coiling, warp yarn head, sizing, coiling, warp doubling, weaving pan head; in the doubling process, stainless steel fiber, bamboo fiber, ramie fiber is gradually wrapped in spandex yarn core Outwardly spun into weft blended yarn; the content of stainless steel fiber, bamboo fiber, ramie fiber and spandex is 5%, 6%, 5% and 84% respectively;

[0022] Weaving: weaving warp yarn blended yarn and weft yarn blended yarn into fabric, the fabric weave adopts plain weave; finishing: after dyeing, softening and shaping, the blended yarn multifunctional fabric of the present in...

Embodiment 2

[0024] In the present embodiment, the contents of stainless steel fiber, copper fiber, carbon fiber and spandex in the warp yarn are 6%, 4%, 4% and 86% respectively; the contents of stainless steel fiber, bamboo fiber, ramie fiber and spandex are respectively 8%, 4%, 4% and 84%; other processes are as described in Example 1, and will not be repeated here.

Embodiment 3

[0026] In the present embodiment, the contents of stainless steel fiber, copper fiber, carbon fiber and spandex in the warp yarn are respectively 9%, 3%, 3% and 85%; the contents of stainless steel fiber, bamboo fiber, ramie fiber and spandex are respectively 6%, 7%, 5% and 82%; other processes are as described in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com