Method for enzymatic synthesis of L-ascorbyl palmitate combined with stirring method under ultrasonic conditions

A technology of ascorbyl palmitate and ascorbic acid, applied in the field of food additive synthesis and processing, can solve the problems of cumbersome operation, low utilization rate, time-consuming and labor-intensive, etc., and achieves the effects of simple operation, improved efficiency, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

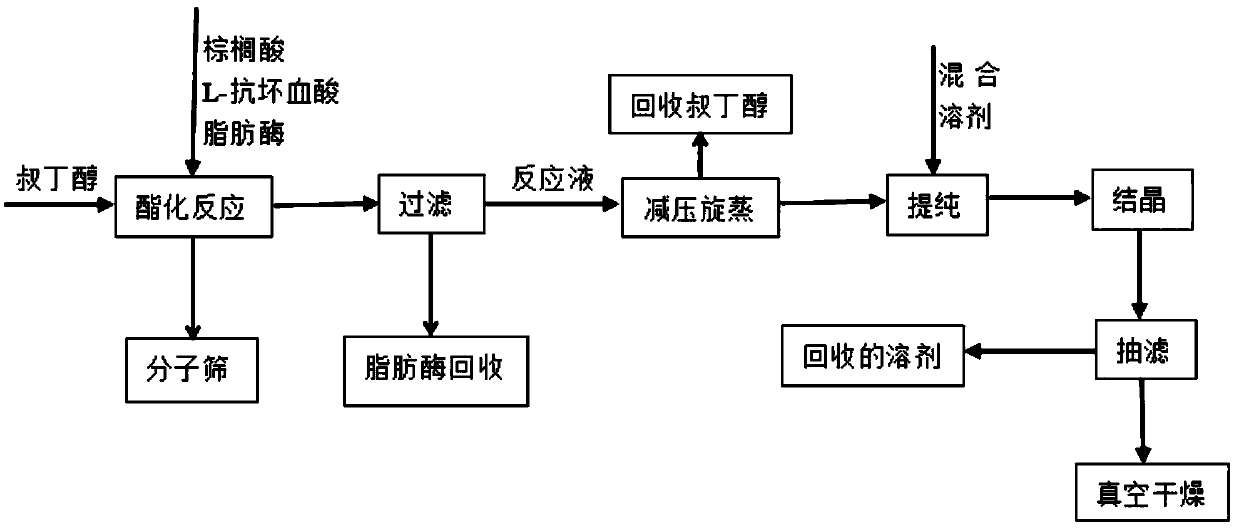

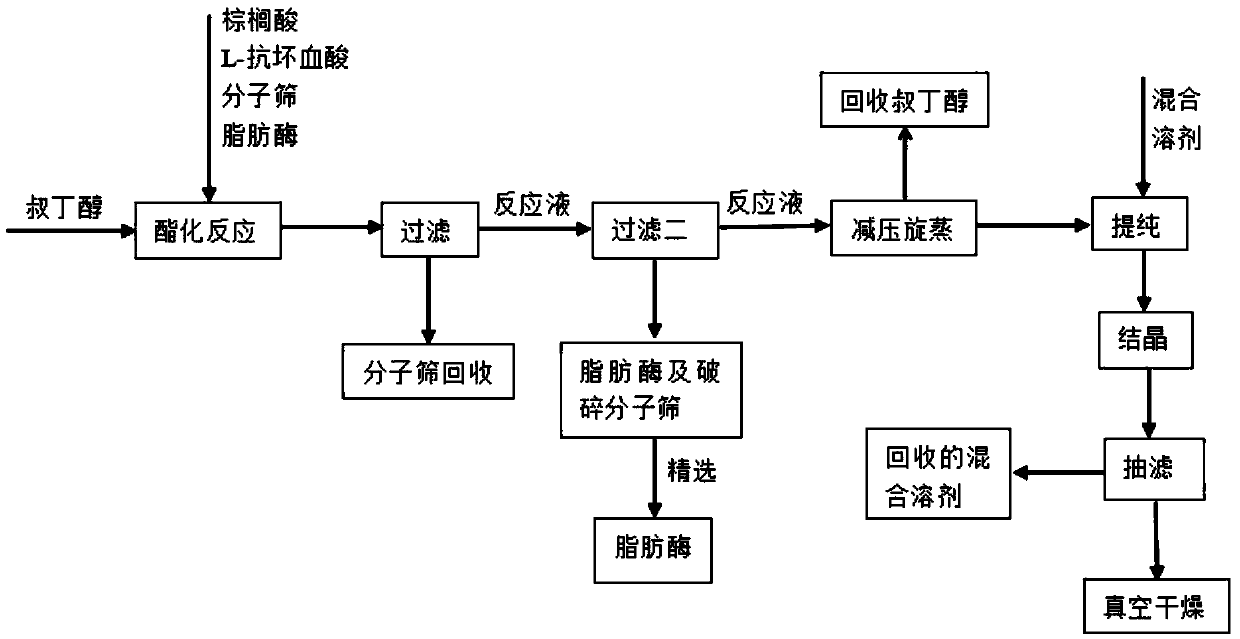

Method used

Image

Examples

Embodiment 1

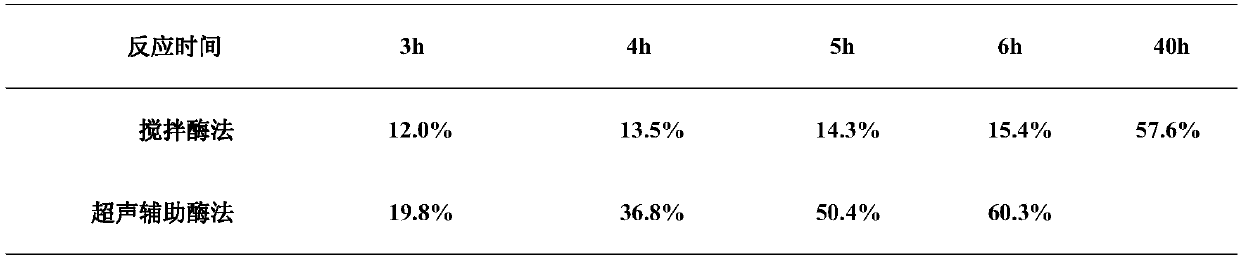

[0032] (1) 15g 4A type molecular sieves are separately installed in the filter; 150ml tert-butanol is added to a closed reaction vessel with a stopper, then 3g L-ascorbic acid and 0.6g Novozymes 435 type ( 435) Lipase, put it under the condition of ultrasonic (ultrasonic power is 140W), start the mixer (rotating speed is 200r / min), after L-ascorbic acid dissolves, add 12g palmitic acid, 55 ℃ water bath constant temperature reaction 3h, 4h, 5h or 6h; the reaction process is to use a circulation pump to carry out uninterrupted circulation of the reaction system between the filter and the reaction vessel. During circulation, the reaction liquid enters from the bottom of the reaction vessel, flows out from the upper feeding port of the reaction vessel, and enters the circulation pipeline from the reaction vessel. Add an 80-mesh screen at the outlet of the lipase to prevent lipase from flowing into the circulation pipeline;

[0033] (2) removing lipase by filtration, the obtained ...

Embodiment 2

[0040] (1) 15g 4A type molecular sieves are separately installed in the filter; 150ml tert-butanol is added to a closed reaction vessel with a stopper, followed by 3g L-ascorbic acid, 1.0g phytic acid and 0.6g Novozymes 435 type ( 435) Lipase, put it under the condition of ultrasonic (ultrasonic power is 140W), start the mixer (rotating speed is 200r / min), after L-ascorbic acid dissolves, add 12g of palmitic acid, 55 ℃ water bath constant temperature reaction for 6h; the reaction process is to use The circulation pump performs uninterrupted circulation of the reaction system between the filter and the reaction vessel. During circulation, the reaction liquid enters from the bottom of the reaction vessel and flows out from the upper feeding port of the reaction vessel. Add 80 mesh Screen to prevent lipase from flowing into the circulation pipeline;

[0041] (2) removing lipase by filtration, the obtained filtrate was distilled off under reduced pressure at 55° C. to remove the ...

Embodiment 3

[0049] (1) 15g 4A type molecular sieves are separately installed in the filter; 150ml tert-butanol is added to a closed reaction vessel with a stopper, followed by 3g L-ascorbic acid, 1.0g phytic acid and 0.6g Novozymes 435 type ( 435) Lipase, put it under the condition of ultrasonic (ultrasonic power is 140W), start the mixer (rotating speed is 200r / min), after L-ascorbic acid dissolves, add 12g of palmitic acid, 55 ℃ water bath constant temperature reaction for 6h; the reaction process is to use The circulation pump performs uninterrupted circulation of the reaction system between the filter and the reaction vessel. During circulation, the reaction liquid enters from the bottom of the reaction vessel and flows out from the upper feeding port of the reaction vessel. Add 80 mesh Screen to prevent lipase from flowing into the circulation pipeline;

[0050] (2) removing lipase by filtration, the obtained filtrate was distilled off under reduced pressure at 55° C. to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com