A kind of graphene band-modified polymer-based foam material and its preparation method and application

A graphene ribbon, foam material technology, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as difficult adsorption capacity, and achieve good compression-resilience mechanical properties , High oil absorption rate, good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

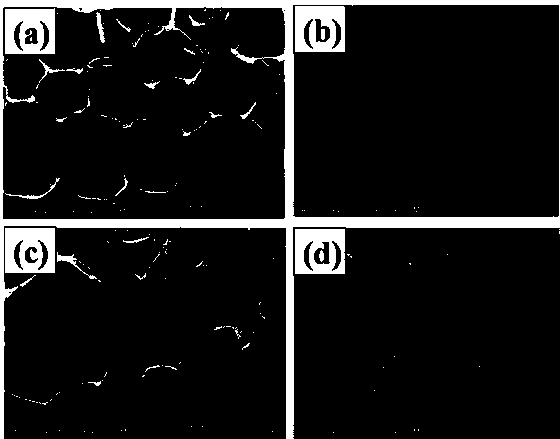

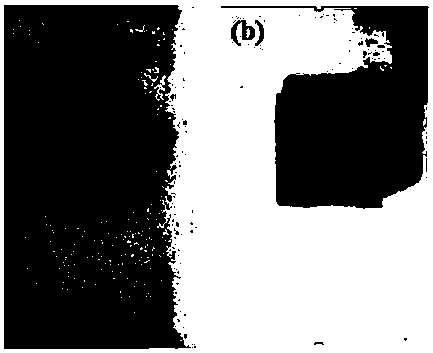

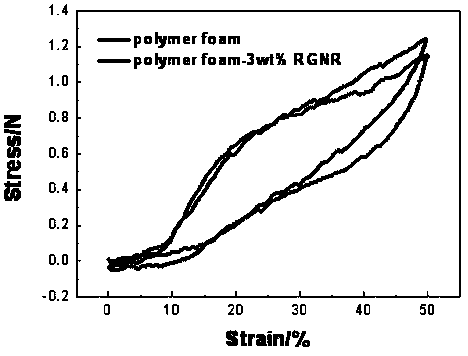

Image

Examples

Embodiment 1

[0028] (1) Configuration of graphene oxide tape aqueous solution: Take the graphene oxide tape viscous solution with a predetermined concentration and dilute it with deionized water to a concentration of 0.8 mg / ml.

[0029] (2) Preparation of polyurethane foam material modified with graphene oxide tape: take 25 ml of graphene oxide tape aqueous solution with a concentration of 0.8 mg / ml, soak 25×25×10 mm polyurethane foam in it, and squeeze and vacuum remove The foam method is to fully soak the foam, then take it out and place it on a copper grid, and blow it to dry.

[0030] (3) Preparation of graphene-modified polyurethane foam material: Take the above-mentioned graphene oxide-modified polyurethane foam material, place it in the upper middle of the reaction kettle, add ammonia water dropwise at the bottom, and place it in an oven at 90 °C for 4 h in an airtight manner. That is, a graphene ribbon-modified polyurethane foam material 1 with a graphene ribbon mass percentage of ...

Embodiment 2

[0034] (1) Configuration of graphene oxide tape aqueous solution: Take the graphene oxide tape viscous solution with a predetermined concentration and dilute it with deionized water to a concentration of 1.1 mg / ml.

[0035] (2) Preparation of polyurethane foam material modified with graphene oxide tape: Take 25 ml of graphene oxide tape water solution with a concentration of 1.1 mg / ml, soak 25×25×10 mm polyurethane foam in it, and squeeze and vacuum remove it. The foam method is to fully soak the foam, then take it out and place it on a copper grid, and blow it to dry.

[0036] (3) Preparation of graphene-modified polyurethane foam material: Take the above-mentioned graphene oxide-modified polyurethane foam material, place it in the upper middle of the reaction kettle, add hydrazine hydrate dropwise at the bottom, and place it in a sealed oven at 90 °C for 3 h. That is, a graphene ribbon-modified polyurethane foam 2 with a graphene ribbon mass percentage of 5% is obtained.

...

Embodiment 3

[0041] (1) Configuration of the aqueous solution of octadecyltrimethoxysilane modified graphene oxide: Take the aqueous solution of octadecyltrimethoxysilane modified graphene oxide with a predetermined concentration and add deionized water to dilute to the concentration The content of octadecyltrimethoxysilane in modified graphene oxide is about 25 wt%.

[0042] (2) Preparation of polyurethane foam material modified with graphene oxide tape: take 35 ml of graphene oxide tape water solution with a concentration of 0.8 mg / ml, soak 25×25×10 mm polyurethane foam in it, and squeeze and vacuum remove it. The foam method is to fully soak the foam, then take it out and place it on a copper grid, and blow it to dry.

[0043] (3) Preparation of graphene-modified polyurethane foam material: The above-mentioned graphene oxide-modified polyurethane foam material was soaked in 50 ml of hydrazine hydrate aqueous solution with a volume ratio of 1:25, and reduced at 80 °C for 3 h. That is, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com