Preparation method and application of polyferric silicate coagulant

A technology of polysilicate ferric silicate and coagulant, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., to achieve the effect of large alum, stable pH, and good affinity and repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

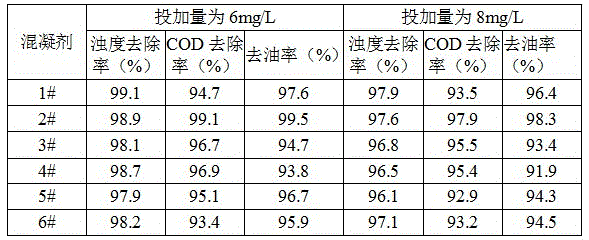

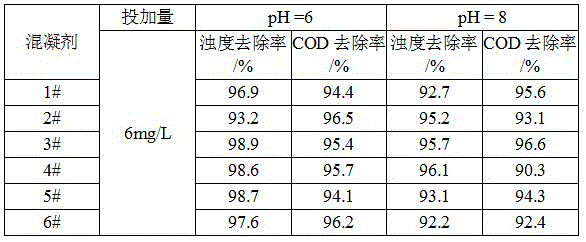

Examples

Embodiment 1

[0019] Embodiment 1: a kind of polysilicate ferric salt coagulant that is used for containing heavy oil waste water, adopts following steps to prepare:

[0020] (1) Add 20g of ferrous sulfate to 30mL of sulfuric acid solution with a concentration of 20% by volume, place it in a digital display constant temperature water bath, and stir at 60°C for 20min to obtain an acidic ferrous salt solution. adding titanium sulfate to the iron salt solution, and stirring at 60°C for 20 minutes to obtain an acidic iron salt solution; wherein, the molar ratio of the iron element in the ferrous sulfate to the titanium element in the titanium sulfate is 1:1;

[0021] (2) After step (1) is stirred, add oxidant m-chloroperoxybenzoic acid, wherein the molar ratio of iron element in ferrous sulfate to m-chloroperbenzoic acid is 100:1, continue stirring for 40 minutes, and add ammonia water to obtain Mixed solution, wherein the mol ratio of ammoniacal liquor and iron element in the ferrous sulfate i...

Embodiment 2

[0024] Embodiment 2: a kind of polysilicate ferric salt coagulant that is used to contain heavy oil waste water, adopts following steps to prepare:

[0025] (1) Add 30g of ferrous sulfate to 80mL of sulfuric acid solution with a concentration of 10% by volume, place it in a digital display constant temperature water bath, and stir at 70°C for 15 minutes to obtain an acidic ferrous salt solution. Add zinc acetate to the iron salt solution, and stir at 70° C. for 15 minutes to obtain an acidic iron salt solution; wherein, the molar ratio of the iron element in the ferrous sulfate to the zinc element in the zinc acetate is 100:50;

[0026] (2) After step (1) is stirred, add oxidant tert-butyl hydroperoxide, wherein the molar ratio of iron element in ferrous sulfate to tert-butyl hydroperoxide is 100:1, continue to stir for 50 minutes, add phosphoric acid and get mixed Solution; wherein the molar ratio of phosphoric acid to the iron element in the ferrous sulfate is 0.5:100;

[0...

Embodiment 3

[0029] Embodiment 3: a kind of polysilicate ferric salt coagulant for containing heavy oil waste water, adopts following steps to prepare:

[0030] (1) Add 40g of ferrous sulfate to 90mL of sulfuric acid solution with a concentration of 20% by volume, place it in a digital display constant temperature water bath, and stir at 70°C for 20min to obtain an acidic ferrous salt solution. Magnesium acetate was added to the iron salt solution, and stirred at 70°C for 20 minutes to obtain an acidic iron salt solution; wherein, the molar ratio of the iron element in the ferrous sulfate to the magnesium element in the magnesium acetate was 100:60;

[0031](2) After step (1) is stirred, add the oxidant cerium ammonium nitrate, wherein the molar ratio of the iron element in the ferrous sulfate to the cerium ammonium nitrate is 100:2, continue stirring for 40 minutes, and obtain a mixed solution after adding acetic acid; The molar ratio of iron element in the ferrous salt is 2.5:100;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com