A kind of treatment agent for printing and dyeing wastewater and preparation method thereof

A printing and dyeing wastewater and treatment agent technology, which is applied in textile industry wastewater treatment, special compound water treatment, light water/sewage treatment, etc., can solve the problems of low treatment efficiency, complicated recycling, and reduced treatment effect, and achieve simple recycling, The effect of shape stability and structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

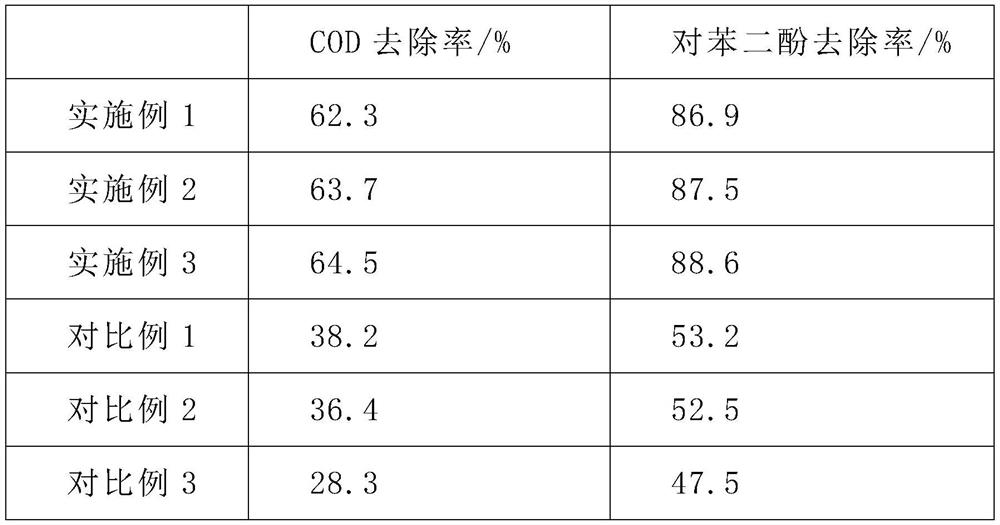

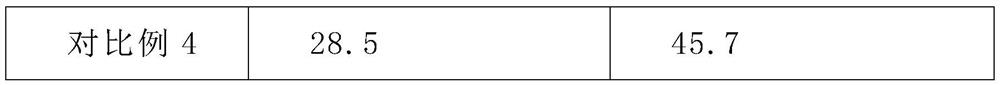

Examples

Embodiment 1

[0033] Mix the phyllosilicate and the hydrochloric acid solution with a mass fraction of 5% according to the mass ratio of 1:5 and pour it into the hydrothermal reaction kettle. After heat preservation and stirring for 1 hour of hydrothermal reaction, release the pressure to normal pressure, discharge the material, filter while it is hot, collect the filter cake, and wash the filter cake with deionized water until the washing liquid is neutral, then vacuum freeze-dry the washed filter cake , to obtain a dry filter cake, and then transfer the dry filter cake into a tube furnace, heat-preserve and roast for 2 hours at a temperature of 150° C., cool to room temperature with the furnace, and discharge the material to obtain a pretreated layered silicate;

[0034] Mix the pretreated layered silicate and graphene oxide at a mass ratio of 1:3, pour into water 50 times the mass of the pretreated layered silicate, and ultrasonically disperse for 2 hours at an ultrasonic frequency of 60 ...

Embodiment 2

[0039] Mix the phyllosilicate and the hydrochloric acid solution with a mass fraction of 8% according to the mass ratio of 1:8 and pour it into the hydrothermal reaction kettle. After heat preservation and stirring for 2 hours of hydrothermal reaction, release the pressure to normal pressure, discharge the material, filter while it is hot, collect the filter cake, and wash the filter cake with deionized water until the washing liquid is neutral, then vacuum freeze-dry the washed filter cake , to obtain a dry filter cake, and then transfer the dry filter cake into a tube furnace, heat-preserve and roast it at 180°C for 2.5 hours, cool to room temperature with the furnace, and discharge the material to obtain a pretreated layered silicate;

[0040] Mix the pretreated layered silicate and graphene oxide at a mass ratio of 1:5, pour into water 60 times the mass of the pretreated layered silicate, and ultrasonically disperse for 3 hours at an ultrasonic frequency of 70 kHz to obtain...

Embodiment 3

[0045] Mix the phyllosilicate and the hydrochloric acid solution with a mass fraction of 10% according to the mass ratio of 1:10 and pour it into the hydrothermal reaction kettle. After heat preservation and stirring for 3 hours of hydrothermal reaction, release the pressure to normal pressure, discharge the material, filter while it is hot, collect the filter cake, and wash the filter cake with deionized water until the washing liquid is neutral, then vacuum freeze-dry the washed filter cake , to obtain a dry filter cake, and then transfer the dry filter cake into a tube furnace, heat-preserve and roast for 3 hours at a temperature of 200° C., cool to room temperature with the furnace, and discharge the material to obtain a pretreated layered silicate;

[0046] Mix the pretreated layered silicate and graphene oxide at a mass ratio of 1:10, pour into water 80 times the mass of the pretreated layered silicate, and ultrasonically disperse for 4 hours at an ultrasonic frequency of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com