Hanging bracket special for movement of steel rail and application method of hanging bracket

A technology of rails and hangers, applied in the field of engineering technology and science, can solve the problems of bulkiness, inconvenient transition, and limited application scope, and achieve the effect of ensuring safety and avoiding contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

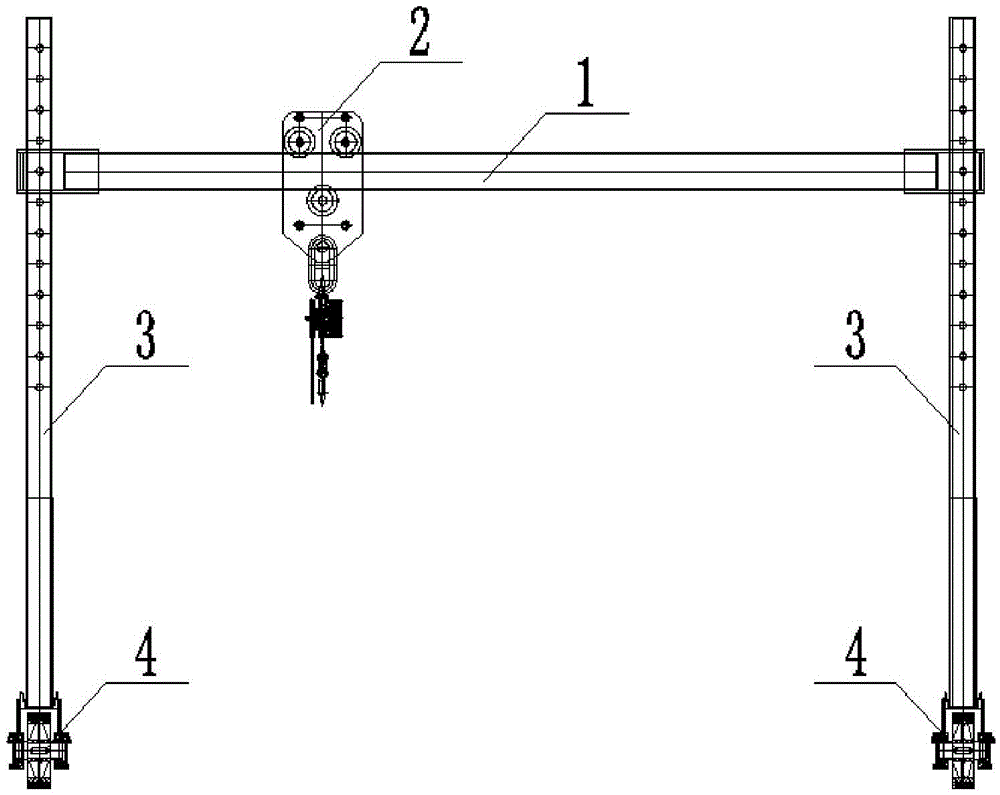

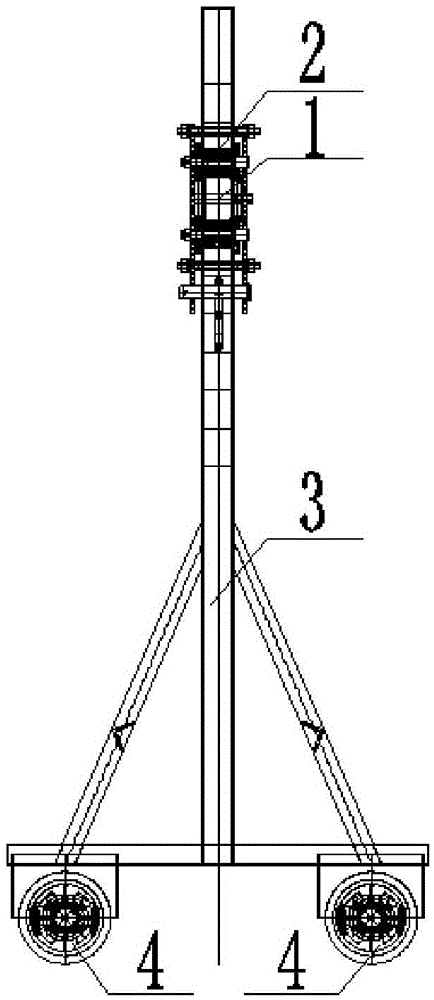

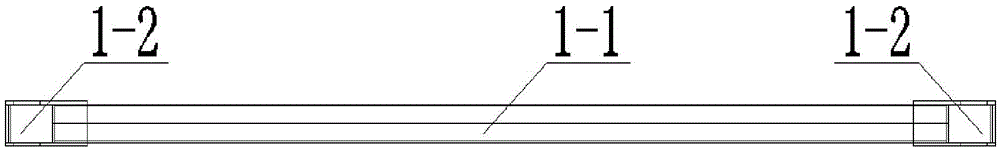

[0037] In order to achieve the above object, the design of the present invention is mainly composed of four parts, which are respectively: crossbeam, suspension rail trolley, supporting legs, running mechanism, such as Figure 1(a) ~ Figure 1(b) shown. The beam is composed of a rectangular steel pipe and a guide sleeve. Both ends of the rectangular steel pipe are welded with the guide sleeve. The rectangular steel pipe adopts 120mm×80mm×6mm cold-drawn seamless steel pipe. The top and bottom of the guide sleeve are designed with round holes matching the size of the outrigger column, and the middle part is designed with a Φ22 round h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com