Bin discharge mechanism of circular bin

A silo, circular technology, applied in the field of couplings, can solve the problems of inability to withstand reverse axial force, time-consuming and labor-intensive, etc., and achieve the effects of low processing cost, convenient manufacturing, and improved bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

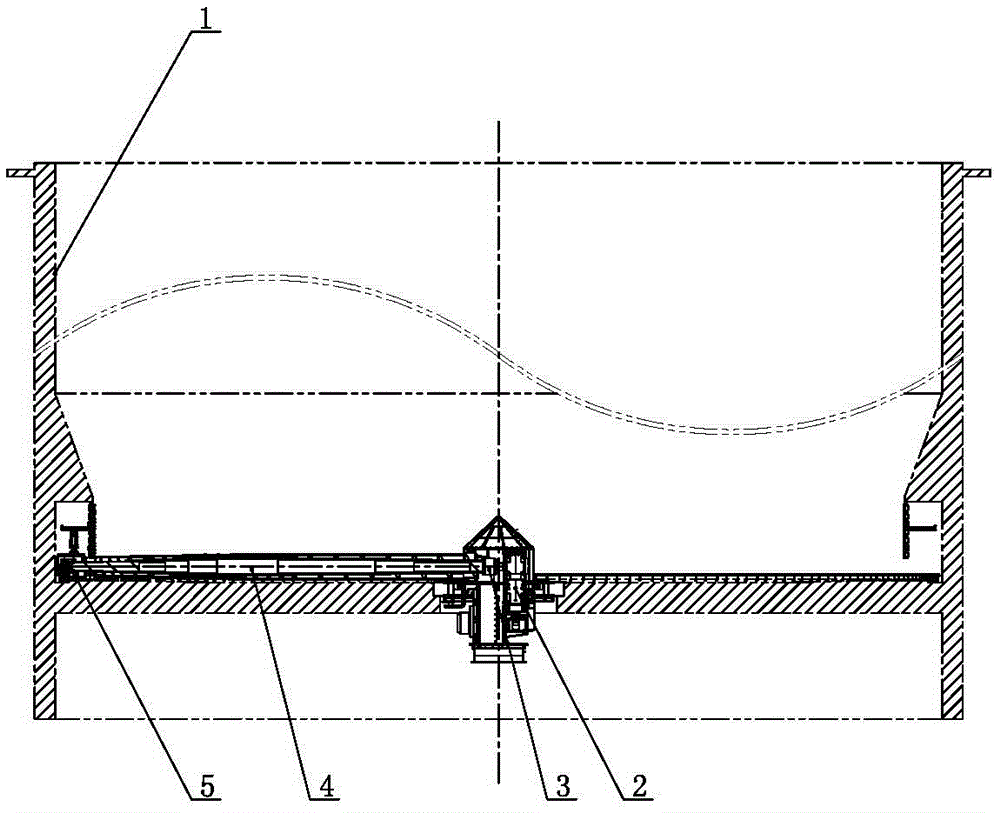

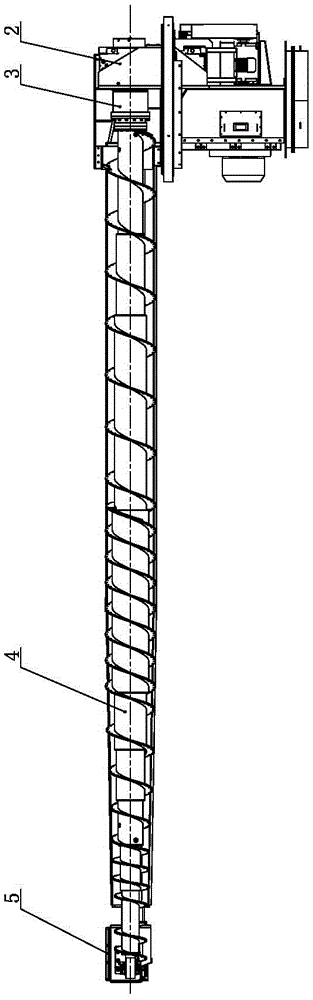

[0031] Such as Figure 1 to Figure 6 As shown, the discharge mechanism of the circular feed bin of the present invention comprises a main reducer 2, a coupling 3, a discharge auger 4 and a tail mechanism 5, the main reducer 2 is located at the center of the feed bin 1, and the main reducer 2 The output shaft of the output shaft is connected with the inner end of the auger shaft of the discharge auger 4 through the coupling 3, the outer end of the auger shaft is connected with the tail mechanism 5, and the parts other than the two ends of the auger shaft are formed by a plurality of hollow long The shafts 4a are nested in sequence and welded to each other, and the closer to the middle part of the auger shaft, the more nesting layers, so that the auger shaft is a stepped shaft with the largest diameter in the middle section, and the outer circumference of the auger shaft is wound with helical blades 4b in the axial direction , the pitch of the helical blade 4b on each step axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com