Vacuum seal structure and manufacturing method thereof

A technology of a vacuum-sealed structure and a manufacturing method, which is applied to the direction of sealed casings, electrical equipment casings/cabinets/drawers, electrical components, etc., can solve the problems of large flange wall thickness and pollution of vacuum chambers, and achieve reduced wall thickness and reduced Effect of small venting area, reducing the possibility of gas remaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

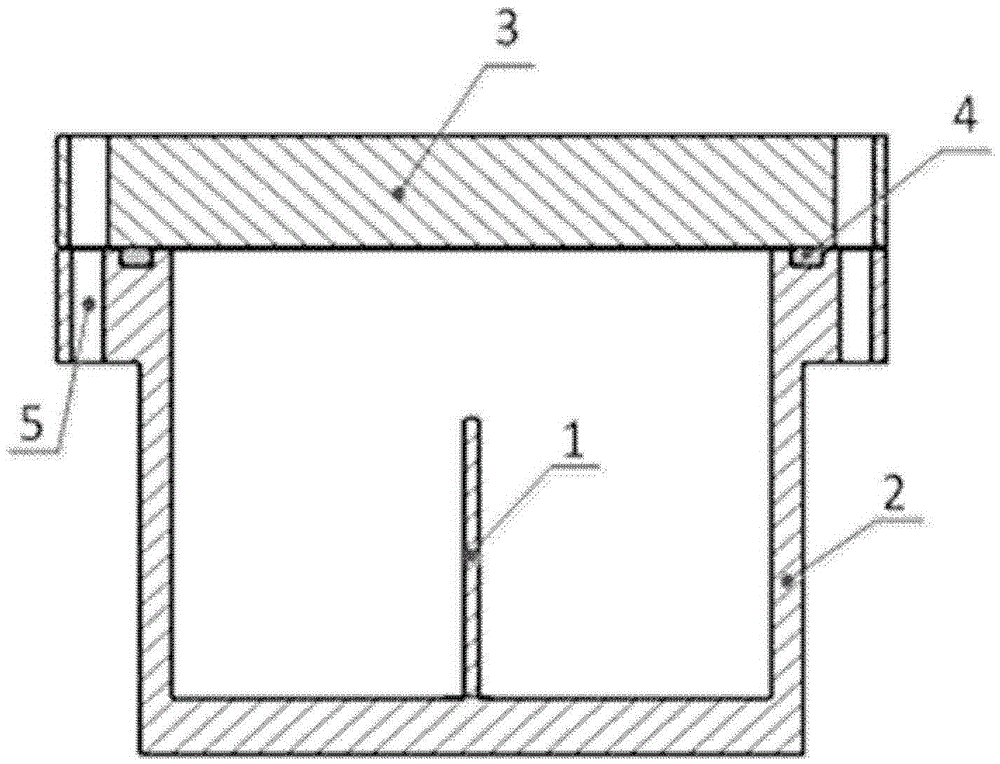

[0021] The present invention proposes a vacuum sealing structure and a manufacturing method thereof. The vacuum sealing structure can be applied to occasions where gas-releasing components need to be sealed. The gas-releasing components are, for example, board-level electronic systems for extreme ultraviolet lithography.

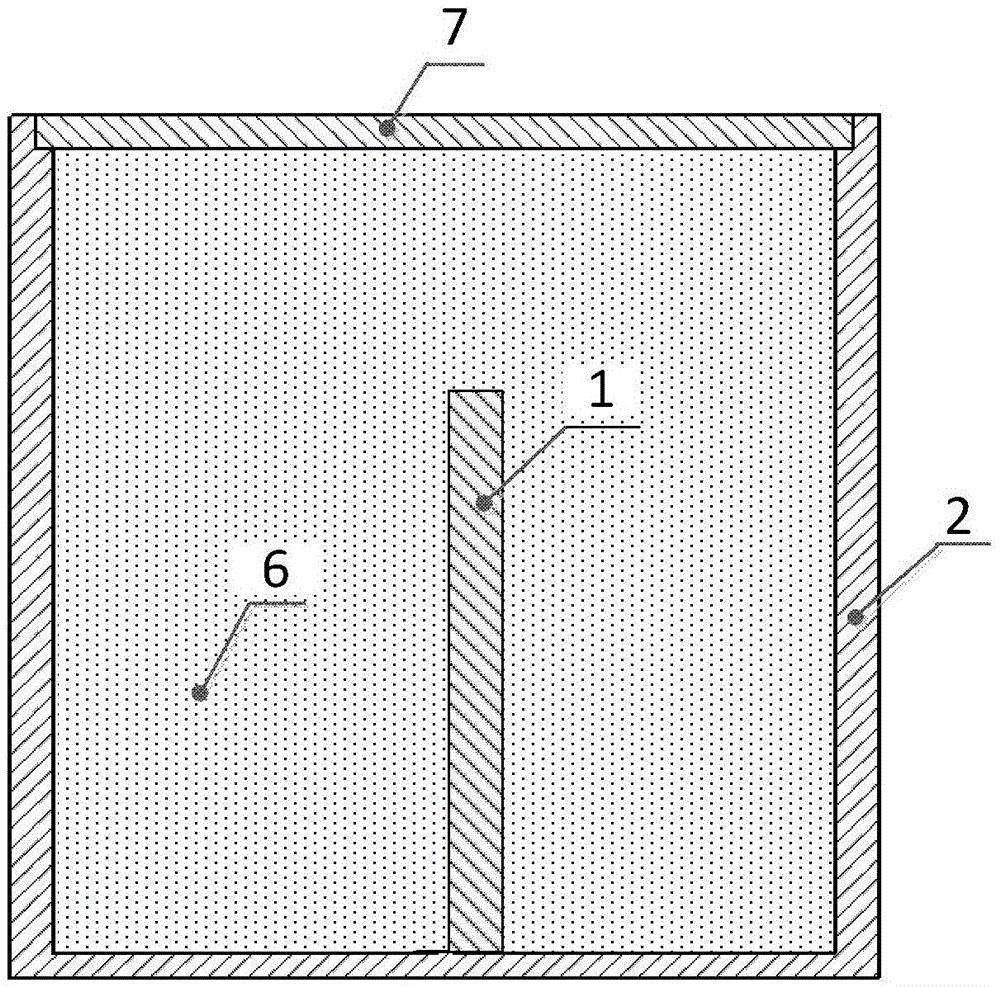

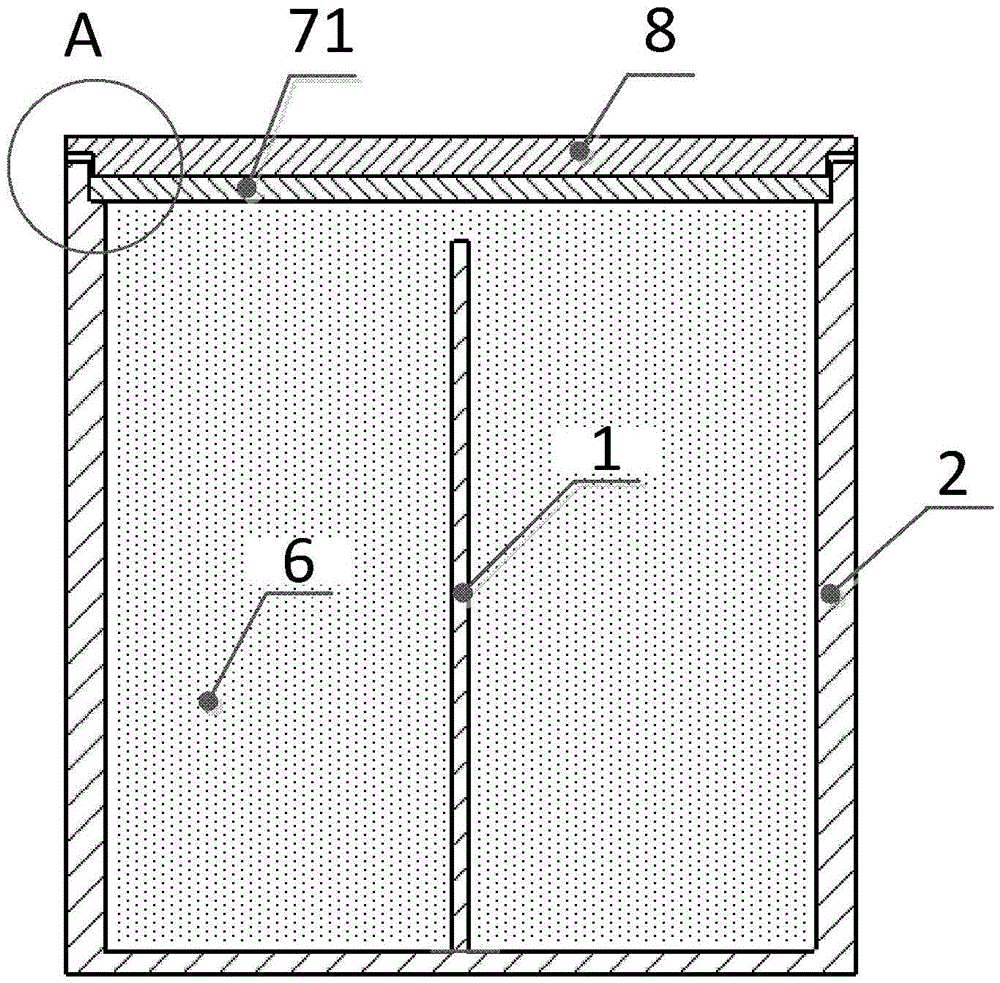

[0022] figure 2 It is a structural schematic diagram of the vacuum sealing structure of the present invention, such as figure 2 As shown, the vacuum-tight structure of the present invention includes a sealed casing 2 , a potting compound 6 and a sealing device 7 . The sealed housing 2 has a chamber, the chamber has a side wall and an open end, and is used to accommodate the deflation element 1; the potting compound 6 is filled in the chamber of the sealed housing 2 and wraps the deflation element 1. The sealing device 7 is used to close the opening end of the cavity of the sealed housing 2 and is in close contact with the potting compound 6 and the side w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com