Contact lenses with water and oxygen channel

A contact lens and channel technology, which is applied to glasses/goggles, optics, instruments, etc., can solve the problems that the oxygen permeability of the lens is not improved, it is not easy to flow back to the inner surface of the lens, and the lens cannot be put into practical application, so as to alleviate the corneal deficiency. effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

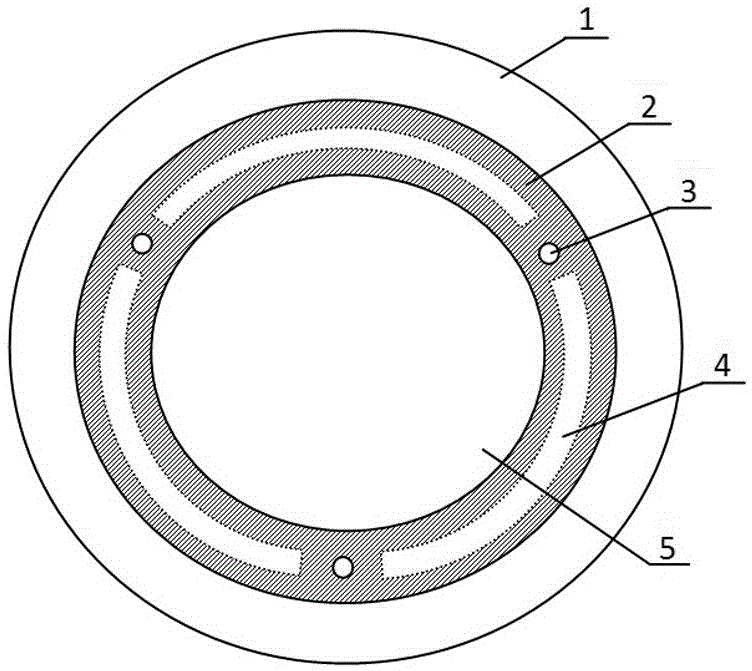

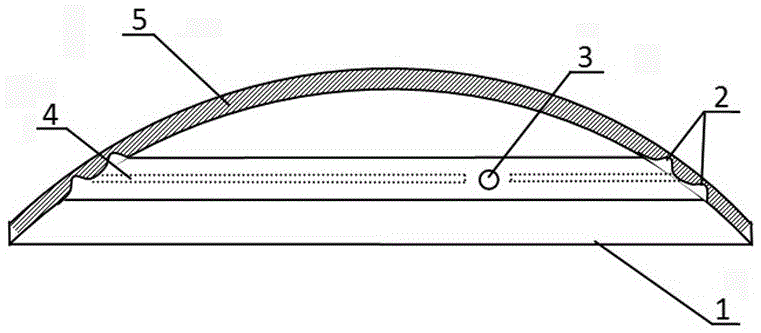

[0012] like figure 1 , 2 As shown, a contact lens with a water-oxygen channel is provided with a concave tear channel 2 with a width of 0.5-1.0 mm on the inner surface of the periphery of the lens central optical zone 5, and 3-8 tear channels 2 with a diameter of 0.5-1.5mm ventilation hole 3. The tear channel 2 is circular. The wider the tear channel 2, the more tears are stored. However, if it is too wide, a large area of thin film will appear on the lens, and the lens is easy to break. In order to increase the amount of tear circulation, 2-5 tear channels 2 are set up. , The channels are separated by a raised ring 4, the thickness of the raised ring 4 is the same as that of a common lens without a tear channel 2, so that no large-area thin layer appears.

[0013] The protruding ring 4 is segmented and non-closed on one circumference, and the ventilating holes 3 are arranged between the ends of the protruding ring 4, so that the tear fluid between the tear channels 2 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com