Horizontal intelligent detection and repair machine for screen printing templates

An intelligent detection and repairing machine technology, applied in conveyor objects, optical testing flaws/defects, printing, etc., can solve the problems of workers' health injury, repeated use, low degree of automation, etc., to save water and improve repairs. The effect of precision and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

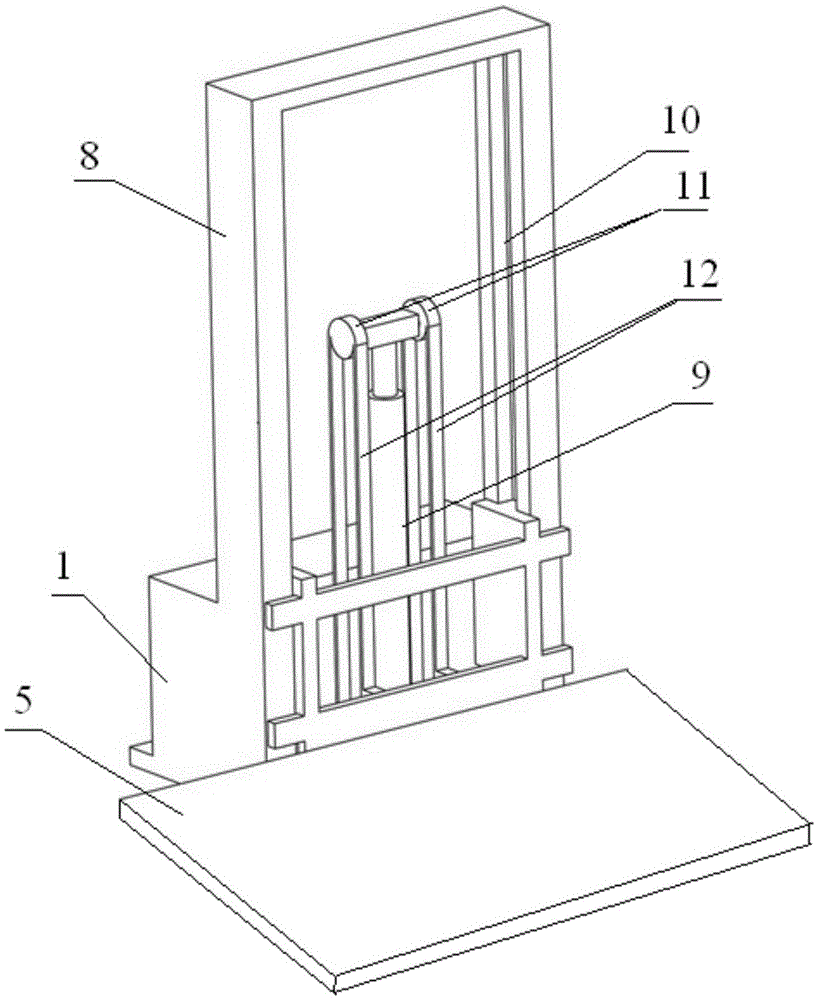

[0035] see figure 1 , figure 2 and image 3 Shown:

[0036] The horizontal screen template intelligent detection and repair machine provided by the present invention includes a lifting transmission mechanism 1, a template box 2, a detection and repairing frame 3 and a mechanical arm 4, wherein the lifting transmission mechanism 1 is arranged at the front end of the template box 2, and the lifting transmission mechanism 1 The lower part of the platform is provided with a lifting platform 5, the template box 2 is placed on the bottom plate of the lifting platform 5, the detection and repair frame 3 is arranged at the rear end of the template box 2, and the template 7 in the template box 2 can be transported to the inspection and repairing station by the lifting transmission mechanism 1. On the frame 3, the mechanical arm 4 is arranged behind the detection and repair frame 3, and the detection and repair device 6 is pivotally connected to the mechanical arm 4, and the template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com