Ignition method, structure and manufacturing method for electric detonator

An electric detonator and electric bridge technology is applied in the field of ignition method, structure and preparation of electric detonator, which can solve the problems of slow action, large heat capacity, poor thermal coupling of substrates, etc., and achieves ideal use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

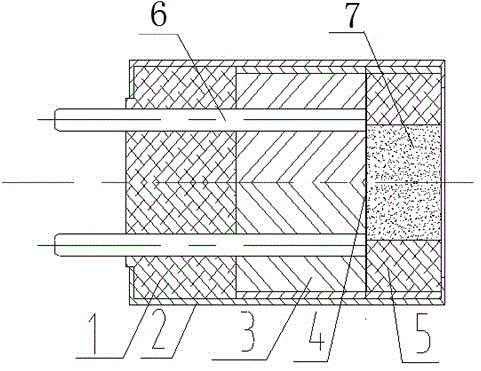

[0014] Embodiments of the present invention: the ignition method of the electric detonator, the primer surface of the electric detonator is provided with a layer of metal film in contact with the primer as the electric bridge of the electric detonator, and the current pulse from the energy storage system flows through the metal film electric bridge, It is heated and vaporized until it breaks down to form plasma; plasma particles penetrate into the adjacent medicine through micro-convective movement, condense on the medicine particles, transfer energy to the medicine particles, and induce chemical reactions to make them ignite .

[0015] The metal thin film electric detonator comprises a shell 2, and a charge pad 5 is arranged in the shell 2, and the middle part of the charge pad 5 is a detonating charge 7, and a plug 3 is arranged at the front end of the charge pad 5, and a plug 3 is provided on the front end of the charge pad 5. The end of the plug is provided with a membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com