Dismantling method of open-pit coal mine end slope bridge

A technology for open-pit coal mine and Duanbang bridge, which is applied in the mining of open-pit mines, earthwork drilling, special mining, etc., can solve the problems of difficult construction, large amount of bulldozer engineering, complicated procedures, etc., so as to shorten construction time and reduce coal consumption. Loss and effect of ensuring coal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

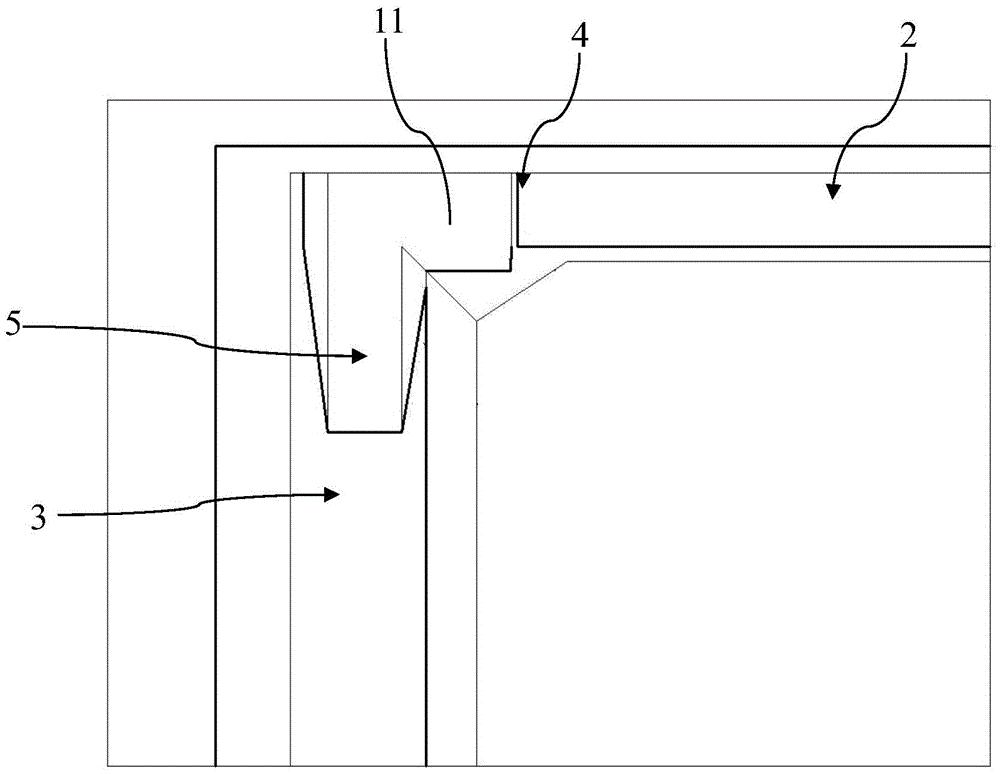

[0024] The specific embodiments of the present invention will be further described below in conjunction with the drawings. The same parts are indicated by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

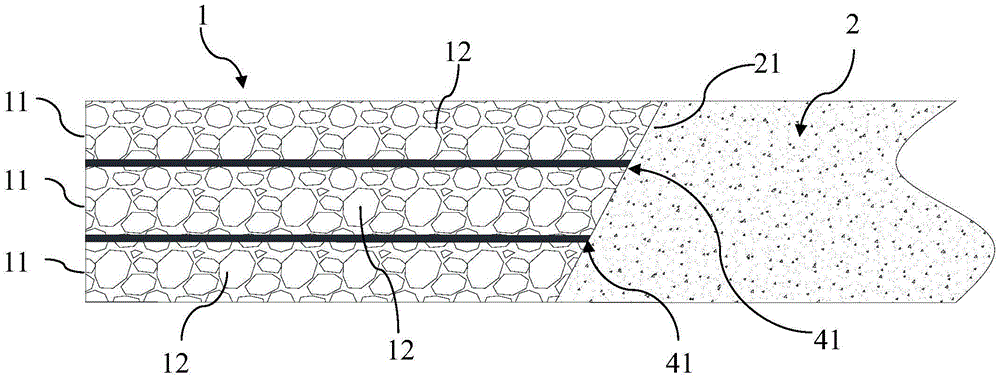

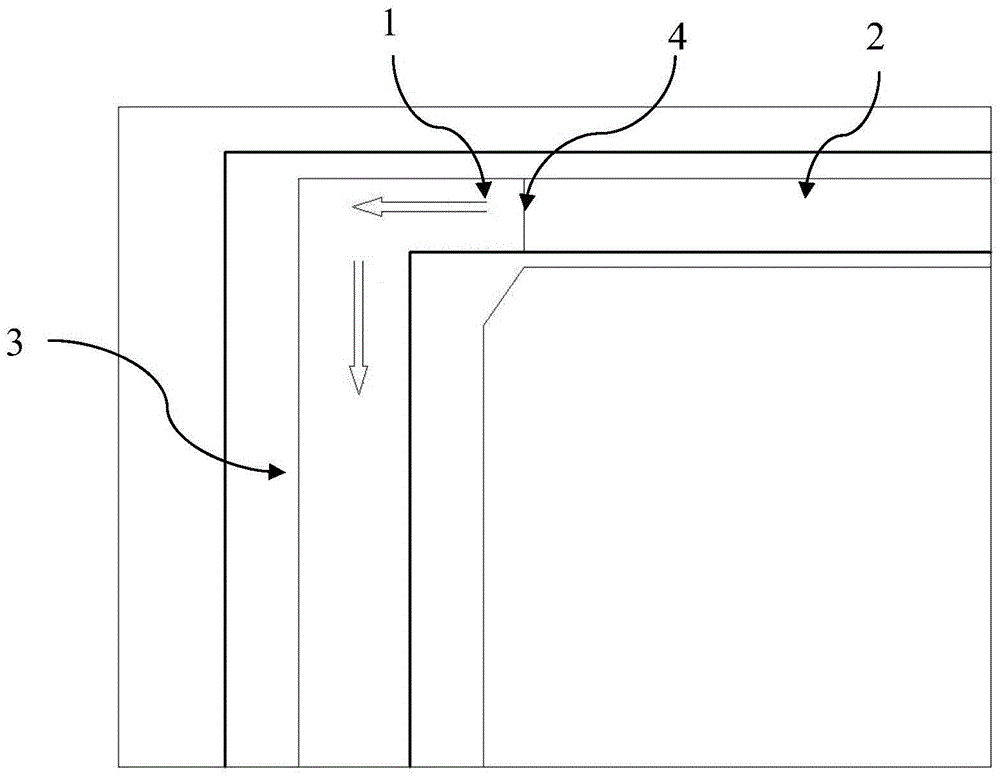

[0025] Such as Figure 1-4 As shown, the present invention provides a method for dismantling an end bridge in an open pit coal mine. The end bridge 1 is formed by a stripping material 12, one end of which covers the coal seam slope 21 of the coal seam 2, and the other end extends to the inner dump 3 within.

[0026] It includes the following steps:

[0027] Step 1: Determine the coal-rock interface 4 between the end bridge 1 and the coal seam 2.

[0028] Step 2: Arrange the hydraulic backhoe at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com