Plant fiber thermal cotton

A technology of plant fiber and thermal insulation cotton, applied in the direction of fiber chemical characteristics, cellulose/protein conjugated artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the problem of solid waste discharge and affect the natural ecological environment , waste disposal problems and other problems, to achieve the effect of reducing the source of human allergies, good flexibility, and solving disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

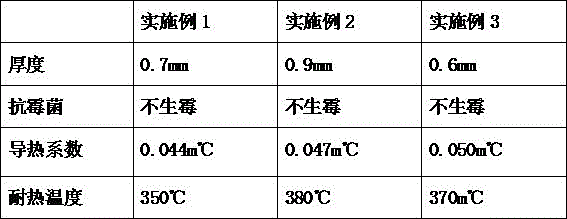

Embodiment 1

[0021] A plant fiber thermal cotton, its formula is as follows: 30 parts of corn fiber, 20 parts of bellflower fiber, 4 parts of plant fiber, 2 parts of nano bamboo charcoal powder, 0.5 part of dimethyl siloxane, 0.2 part of zinc sulfate, 2 parts of polyvinylpyrrolidone 1 part of carnauba wax, 20 parts of 1-butyl-3-methylimidazole dibutyl phosphate, 3 parts of polytetrafluoroethylene fiber, 5 parts of polypropylene fiber, and 20 parts of water.

[0022] The raw material of the plant fiber mainly comes from sun-dried weeds.

[0023] The particle diameter of described nano bamboo charcoal powder is 10nm.

[0024] The preparation method of described plant fiber thermal insulation cotton is as follows:

[0025] (1) Add corn fiber, bellflower fiber and plant fiber to the water and boil for 10 minutes, then remove and dry, degrease and ultrafinely pulverize;

[0026] (2) Add nano-bamboo charcoal powder and carnauba wax to the reaction kettle to react and boil for 10 minutes to rea...

Embodiment 2

[0031] A plant fiber thermal cotton, its formula is as follows: 45 parts of corn fiber, 30 parts of bellflower fiber, 10 parts of plant fiber, 4 parts of nano bamboo charcoal powder, 0.9 fen of dimethyl siloxane, 0.4 part of zinc sulfate, 4 parts of polyvinylpyrrolidone 5 parts of carnauba wax, 50 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 9 parts of polytetrafluoroethylene fiber, 9 parts of polypropylene fiber, and 30 parts of water.

[0032] The raw material of the plant fiber mainly comes from sun-dried weeds.

[0033] The particle diameter of described nano bamboo charcoal powder is 100nm.

[0034] The preparation method of described plant fiber thermal insulation cotton is as follows:

[0035] (1) Add corn fiber, bellflower fiber and plant fiber to the water and boil for 10 minutes, then remove and dry, degrease and ultrafinely pulverize;

[0036] (2) Add nano-bamboo charcoal powder and carnauba wax to the reaction kettle to react and boil for 10 minutes to...

Embodiment 3

[0041] A kind of plant fiber warm cotton, its formula is as follows: 37 parts of corn fiber, 25 parts of bellflower fiber, 7 parts of plant fiber, 3 parts of nano bamboo charcoal powder, 0.7 part of dimethyl siloxane, 0.3 part of zinc sulfate, 3 parts of polyvinylpyrrolidone, Brazil 3 parts of palm wax, 35 parts of 1-butyl-3-methylimidazolium dibutyl phosphate, 7 parts of polytetrafluoroethylene fiber, 7 parts of polypropylene fiber, 25 parts of water.

[0042] The raw material of the plant fiber mainly comes from sun-dried weeds.

[0043] The particle diameter of described nano bamboo charcoal powder is 57nm.

[0044] The preparation method of described plant fiber thermal insulation cotton is as follows:

[0045] (1) Add corn fiber, bellflower fiber and plant fiber to the water and boil for 10 minutes, then remove and dry, degrease and ultrafinely pulverize;

[0046] (2) Add nano-bamboo charcoal powder and carnauba wax to the reaction kettle to react and boil for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com