Method for in-situ synthesis of Si3N4-Si2N2O-TiN ternary compound powder

A ternary composite and in-situ synthesis technology, applied in the field of composite ceramic materials, can solve the problems of difficult dispersion, non-uniform and fine distribution, easy agglomeration, etc., and achieve the effects of improving ceramic performance, promoting high performance, and accelerating nitriding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In situ synthesis of Si of the present invention 3 N 4 -Si 2 N 2 The method for O-TiN ternary composite powder, comprises the steps:

[0033] (1) Using Si powder and butyl titanate as raw materials, the mass fraction of Si powder is 73%, and the mass fraction of butyl titanate is 27%. With ethanol as solvent, Si 3 N 4 The ball is a ball milling medium, mixed on a planetary ball mill for 12 hours, after mixing and drying, a uniformly mixed Si-TiO 2 Composite powder, wherein the mass fraction of Si powder is 92%, TiO 2 The mass fraction is 8%.

[0034] (2) Si-TiO 2 Composite powder dry pressing to obtain Si-TiO 2 Green body, Si-TiO 2 Put the green body into a graphite crucible, raise the temperature to 1400°C at a heating rate of 10°C / min, and keep it warm for 2 hours. The atmosphere of the whole process is 1atm nitrogen, and Si is synthesized in situ. 3 N 4 -Si 2 N 2 O-TiN ternary composite powder.

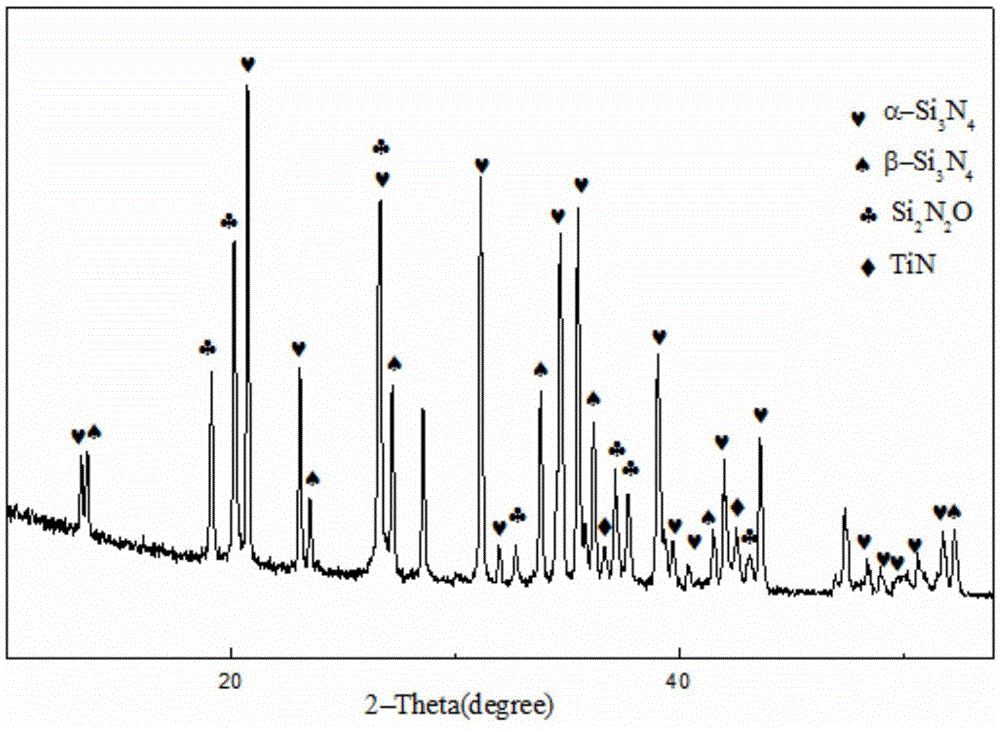

[0035] The Si prepared in this example 3 N 4 -Si 2 N 2 ...

Embodiment 2

[0037] The in-situ synthesis of Si in this embodiment 3 N 4 -Si 2 N 2 The method of O-TiN ternary composite powder is as follows:

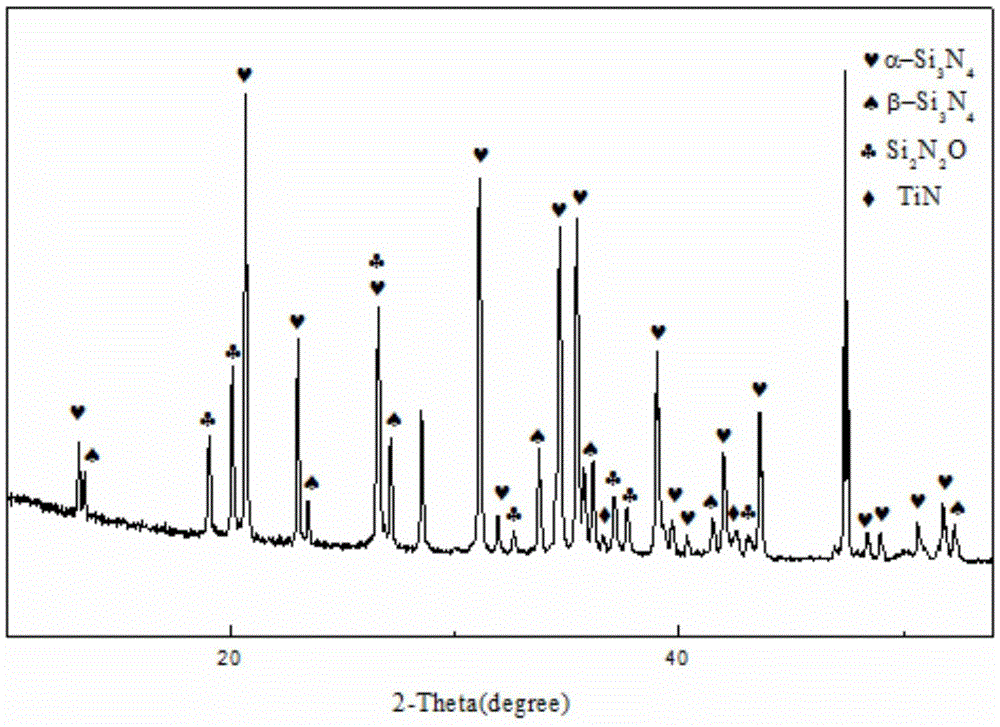

[0038] According to the mass fraction of Si powder is 82%, the mass fraction of butyl titanate is 18%, with ethanol as solvent, Si 3 N 4 The ball is a ball milling medium, mixed on a planetary ball mill for 12 hours, mixed and dried to obtain Si-TiO 2 Composite powder, where Si and TiO 2 The mass fraction ratio is 95%: 5%, and Si is synthesized in situ according to the method of Example 1 3 N 4 -Si 2 N 2 O-TiN ternary composite powder, in which the temperature is raised to 1400 ° C for 2 hours. Prepared Si 3 N 4 -Si 2 N 2 O-TiN ternary composite powder, Si 3 N 4 、Si 2 N 2 O and TiN particle sizes are 3.7μnm, 3.8μnm, 0.7μnm, Si 3 N 4 : Si 2 N 2 O: TiN mass fraction ratio is 89.9%: 7.7%: 2.4%, and Si 2 N 2 O and TiN are uniformly distributed on Si 3 N 4 middle.

Embodiment 3

[0040] The in-situ synthesis of Si in this embodiment 3 N 4 -Si 2 N 2 The method of O-TiN ternary composite powder is as follows:

[0041] According to Si powder mass fraction of 92%, butyl titanate mass fraction of 8% for batching, with ethanol as solvent, Si 3 N 4 The ball is a ball milling medium, mixed on a planetary ball mill for 12 hours, mixed and dried to obtain Si-TiO 2 Composite powder, where Si and TiO 2 The mass fraction ratio is 98%: 2%, and Si is synthesized in situ according to the method of Example 1 3 N 4 -Si 2 N 2 O-TiN ternary composite powder, in which the temperature is raised to 1400 ° C for 2 hours. Prepared Si 3 N 4 -Si 2 N 2 O-TiN ternary composite powder, Si 3 N 4 、Si 2 N 2 O and TiN particle sizes are 3.1μnm, 3μnm, 0.5μnm, Si 3 N 4 : Si 2 N 2 O: TiN mass fraction ratio is 96%: 3%: 1%, and Si 2 N 2 O and TiN are uniformly distributed on Si 3 N 4 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com