Beta-mannase for decoloration and application of beta-mannase

A mannanase and application technology, applied in the directions of glycosylase, enzyme, hydrolase, etc., can solve the problems of toxic by-products, high energy consumption and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

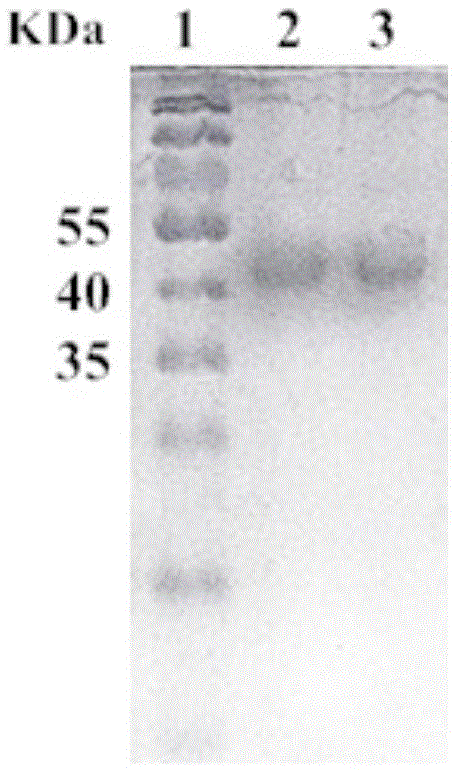

[0018] Example 1. Obtaining of β-mannanase

[0019] Transfer the overnight cultured B. licheniformis HDGLJT-01 seed solution to konjac gum fermentation enzyme production medium, shake and culture at 37°C and 160rpm for 48h, take 40mL of fermentation broth, centrifuge at 4500r / min, 4°C for 20min, and obtain the supernatant , the crude enzyme solution. The crude enzyme liquid was purified by acetone precipitation method, and further purified by ion exchange chromatography and gel filtration chromatography. Specifically, the concentrated enzyme solution was added to a well-balanced DEAE-sepharoseFF ion exchange column, and 0.1mol / L NaCl and 0.005mol / L Tris-HCl with a pH of 7.0 were used for gradient elution, and the eluate was collected. Detection of enzyme activity and protein content. Add 5mL of ion-exchange-purified enzyme solution to a well-balanced sepadexG-75 column, use pure water as the eluent, and the elution flow rate is 0.5mol / min, collect the eluate, and detect th...

Embodiment 2

[0020] Example 2. Partial property analysis of β-mannanase

[0021] The activity analysis of the β-mannanase of the present invention includes the optimum temperature and thermostability of the enzyme and the optimum pH and pH stability of the enzyme.

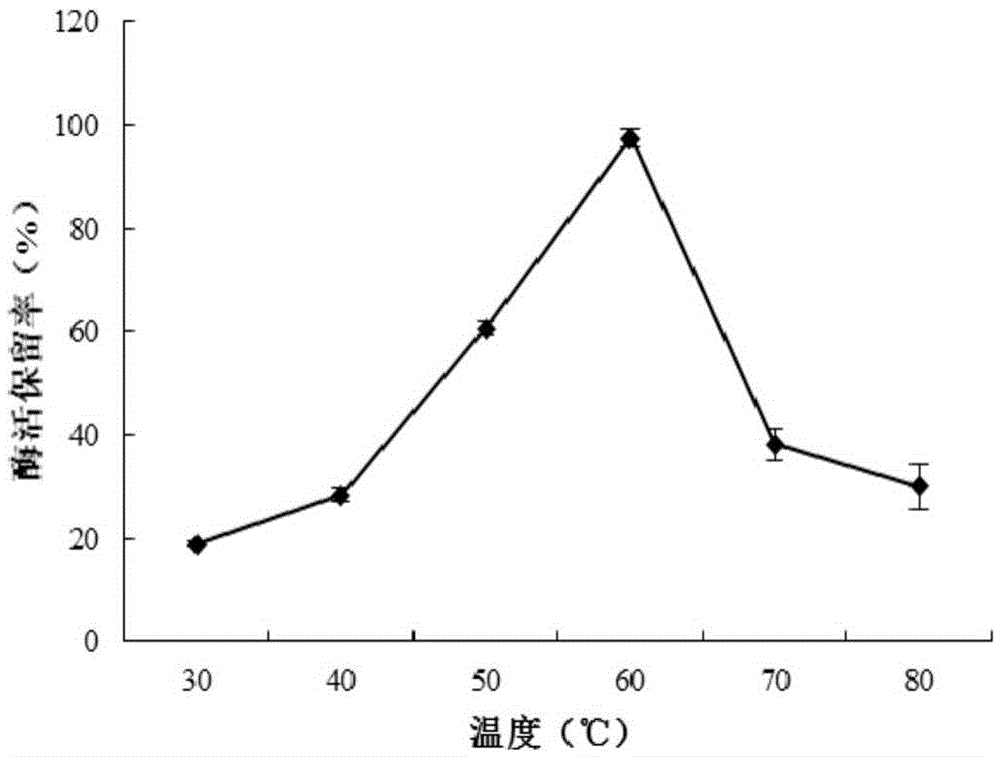

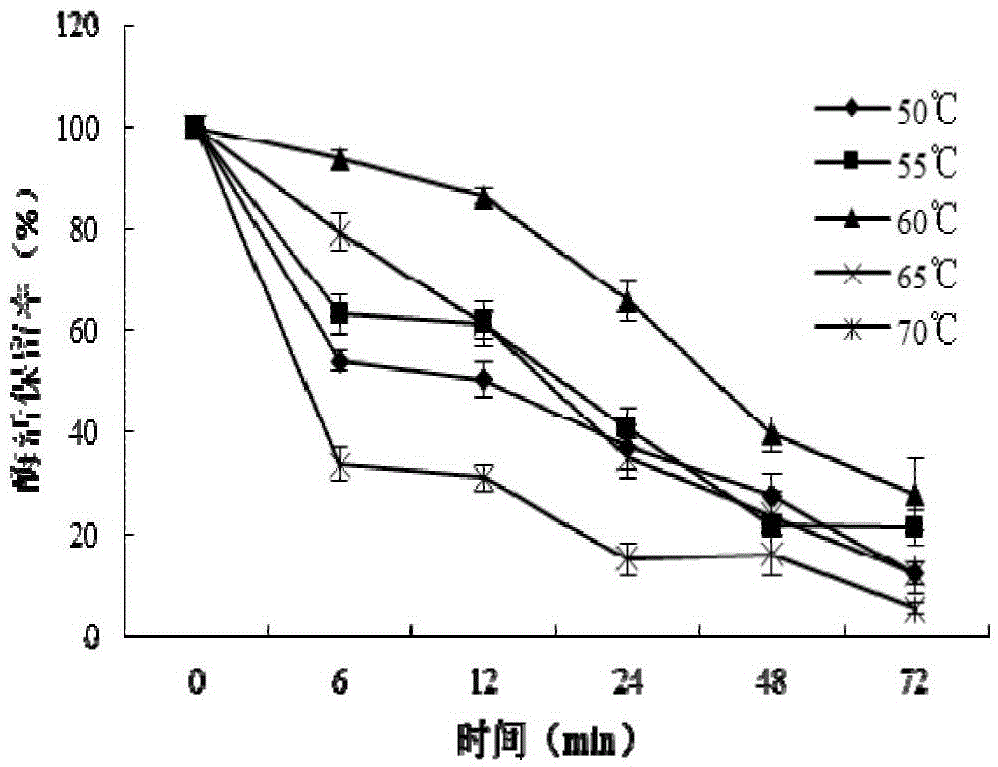

[0022] (1) Optimum temperature and thermostability of β-mannanase

[0023] Take 2mL Tris-HCl buffer solution (0.1mol / L, pH 8.0) and mix it with 0.5mL pure enzyme solution. After incubation for 30min, immediately measure the enzyme activity. Enzyme activity is used as a control (this enzyme activity is the original enzyme activity, ie 100%), and the enzyme activity retention rate at different temperatures is calculated to determine the optimum temperature of β-mannanase. the result shows( figure 2 ), the optimal temperature of the enzyme is 60°C, indicating that the enzyme is more heat-resistant.

[0024] Mix 2mL of Tris-HCl buffer solution with 0.5mL of pure enzyme solution at 30°C, 40°C, 50°C, 60°C, 70°C and 80°C, and me...

Embodiment 3

[0028] The decolorization effect of embodiment 3.β-mannanase

[0029] Table 1 The dyes used in the decolorization test

[0030]

[0031]

[0032] Eight dyes with different structures (Table 1) were selected to detect the decolorization ability of β-mannanase. A certain amount of β-mannanase and dye were mixed, 37°C, 160rpm shaking reaction, at 0, 6 and 12h, full-wavelength scanning was performed to detect the residual situation of the dye. the result shows( Figure 7 ), β-mannanase has the best decolorization effect on azo dyes, among which methyl orange, Congo red and Dardan yellow are the best in decolorization. 50%, better decolorization. The decolorization effect of triaryl methane dyes is better, among which the decolorization rate of water-soluble aniline blue, rubenite green and phenol red is about 90%, and the effect is obvious; the decolorization rate of crystal violet is more than 50%, and the decolorization effect is better.

[0033] The decolorization e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com