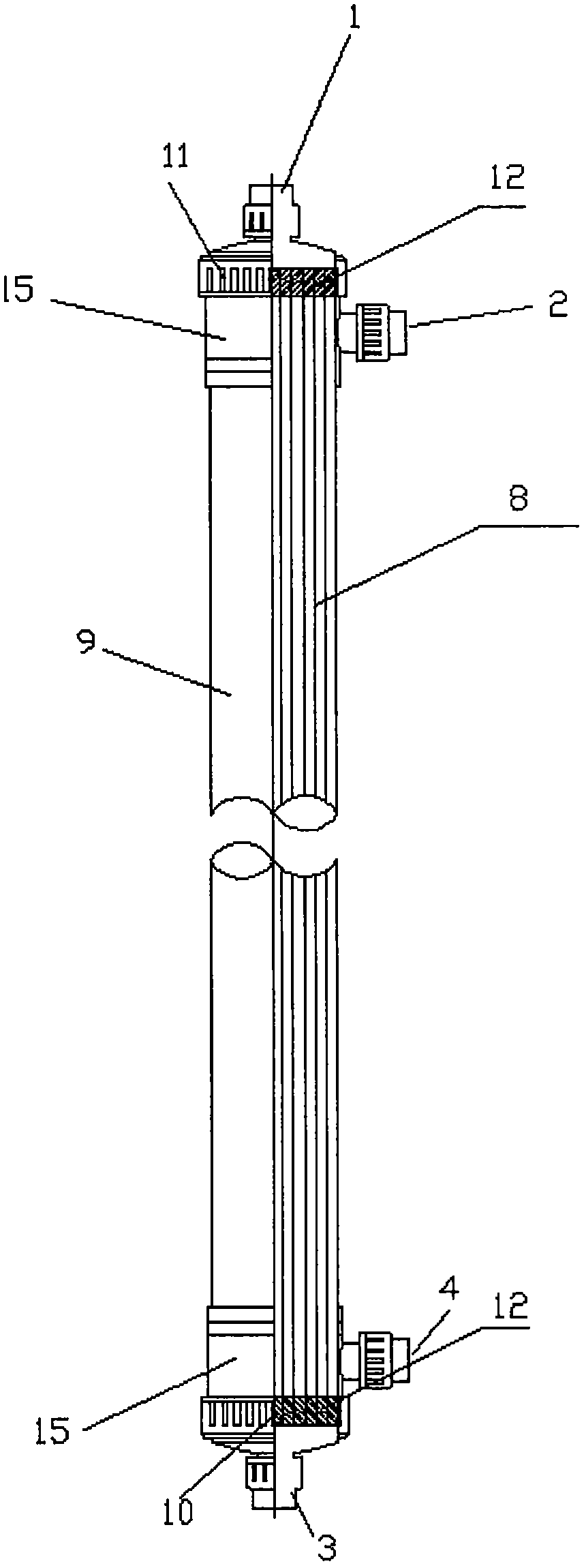

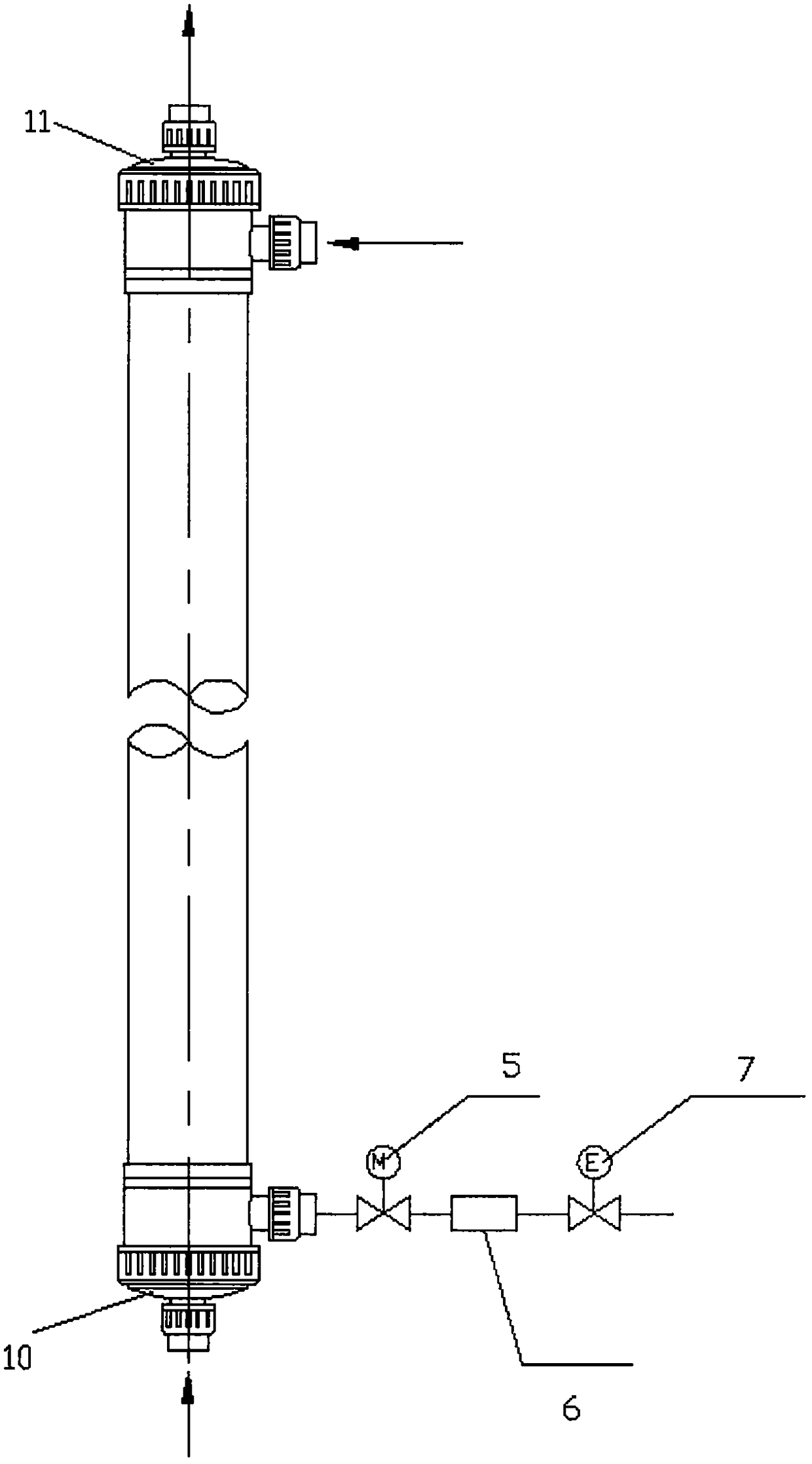

Membrane module for removing ammonia nitrogen from landfill leachate and method for removing ammonia nitrogen from landfill leachate

A landfill leachate and membrane module technology, which is applied in the field of ammonia nitrogen treatment in landfill leachate, can solve the problems of excessive ammonia nitrogen content and high treatment costs, and achieve the effects of large flow volume, improved treatment capacity, and fast flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

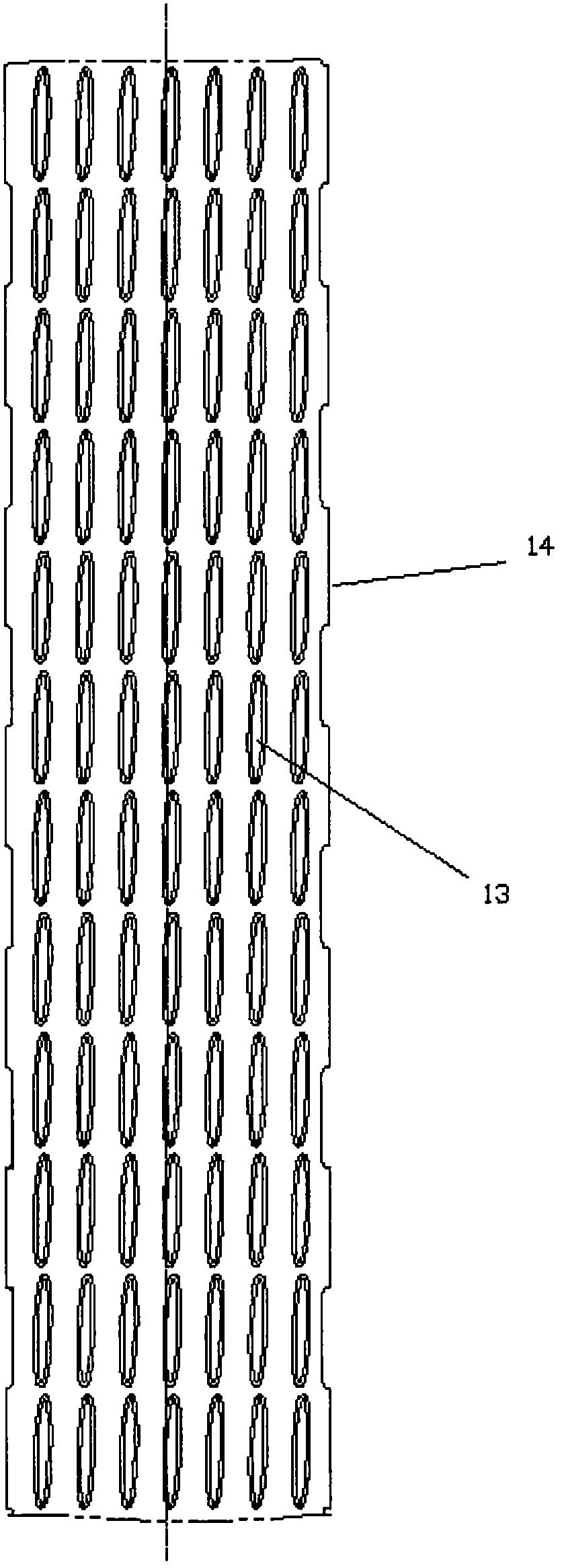

[0037] The membrane filament assembly adopting the structure of the present invention uses membrane filaments with a diameter of 500 microns, an inner diameter of 350 microns, and an interval between the membrane filaments and the membrane filaments of 80 microns. The pH value of the landfill leachate is adjusted to 11, the pH value of the acid absorption liquid is 2, the pressure of the landfill leachate is 0.01-0.15MPa, the pressure value of the acid absorption liquid is 0.02-0.15MP, the acid absorption liquid flow rate is 350L / h, and the landfill leachate flow rate 250L / h, the temperature of landfill leachate and acid absorption liquid is 10-50℃, the COD value of landfill leachate is less than or equal to 50,000 mg per liter, the TDS value is less than or equal to 35%, and the ammonia nitrogen content is unlimited. The treated landfill leachate has an ammonia nitrogen content of 15 mg / L.

Embodiment 2

[0039] Using membrane filaments with a diameter of 450 microns and an inner diameter of 300 microns, the PH value of the landfill leachate is 11, the pH value of the acid absorption liquid is 1.5, the pressure of the landfill leachate is 0.07MPa, the pressure value of the acid absorption liquid is 0.09MP, and the acid absorption The liquid flow rate is 210L / h, the landfill leachate flow rate is 350L / h, and the rest are the same as in Example 1. The treated landfill leachate has an ammonia nitrogen content of 14 mg / L.

Embodiment 3

[0041] Using membrane filaments with a diameter of 400 microns and an inner diameter of 250 microns, the PH value of the landfill leachate is 11, the pH value of the acid absorption liquid is 1, the pressure of the landfill leachate is 0.2MPa, the pressure value of the acid absorption liquid is 0.3MP, and the acid absorption The liquid flow rate is 280L / h, the landfill leachate flow rate is 300L / h, and the rest are the same as in Example 1. The treated landfill leachate has an ammonia nitrogen content of 12 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com