Air refrigeration circulating device with small ram air flow

A ram air and flow control technology, applied in air handling equipment, transportation and packaging, aircraft parts, etc., can solve the problems of large performance compensation loss, unfavorable aircraft stealth, etc., and achieve large cooling capacity, high reliability, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

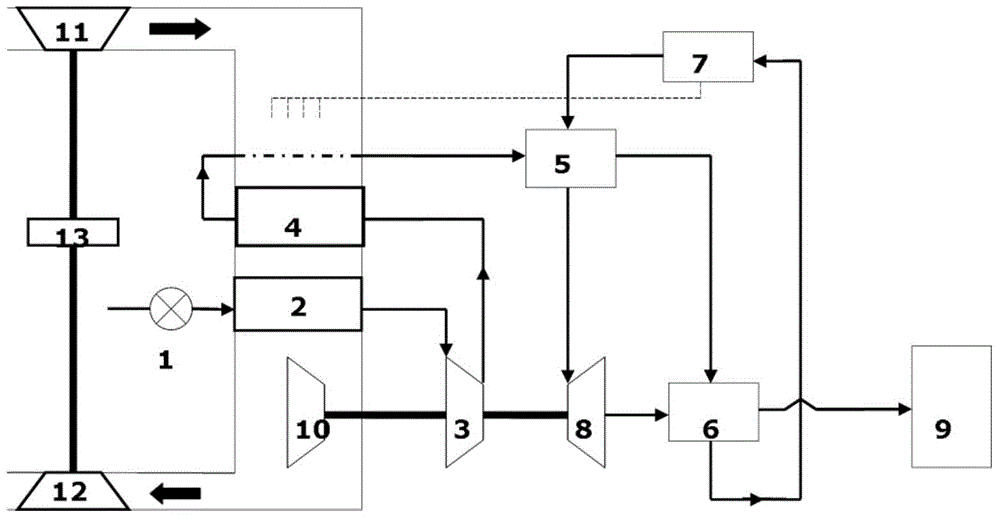

[0015] An air refrigeration cycle device with a small ram air flow rate, including a flow control valve 1, a primary radiator 2, a compressor 3, a secondary radiator 4, a regenerator 5, a condenser 6, a water separator 7, a turbine 8, Cockpit 9, fan 10, second turbine 11, second fan 12, motor 13;

[0016] The engine bleed air regulated by the flow control valve 1 is cooled by the hot side of the primary radiator 2, then compressed by the compressor 3 into high-temperature and high-pressure gas, and then passes through the hot side of the secondary radiator 4, the hot side of the regenerator 5, and the condenser in sequence 6 The hot side and the water separator 7 further reduce the temperature and separate the water, and finally enter the turbine 8 to expand and cool down, and then pass through the cold side of the condenser 6 and supply it to the cabin 9;

[0017] The water separated by the water separator 7 is sprayed into the cold side of the secondary radiator 4 and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com