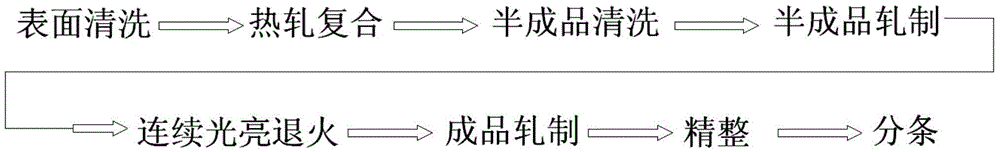

Cu/Mo/Cu laminated metal coiled strip and continuous machining method

A technology of layered metal and processing method, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve the problems of complex plate method, dangerous production process, difficult realization, etc., and achieve the guarantee Product quality consistency, good production application value, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

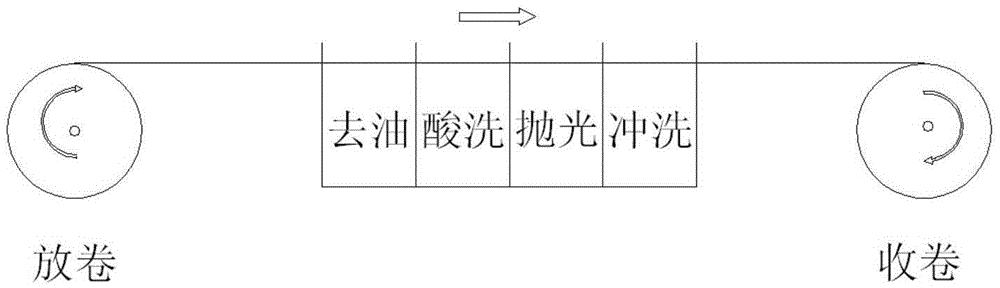

[0040]1. Surface cleaning: Unwind the copper (Cu) tape with a thickness of 1.0mm on the equipment with the function of rewinding and unwinding, continuously degrease online, pickle with 10% dilute sulfuric acid, and polish with a round scouring pad , Rinse with pure water; Unwind the molybdenum (Mo) tape with a thickness of 1.8mm on the equipment with the function of rewinding and unwinding, continuously degrease online, pickle with 20% acid solution, polish with round steel wire brush wheel, clean Rinse with water.

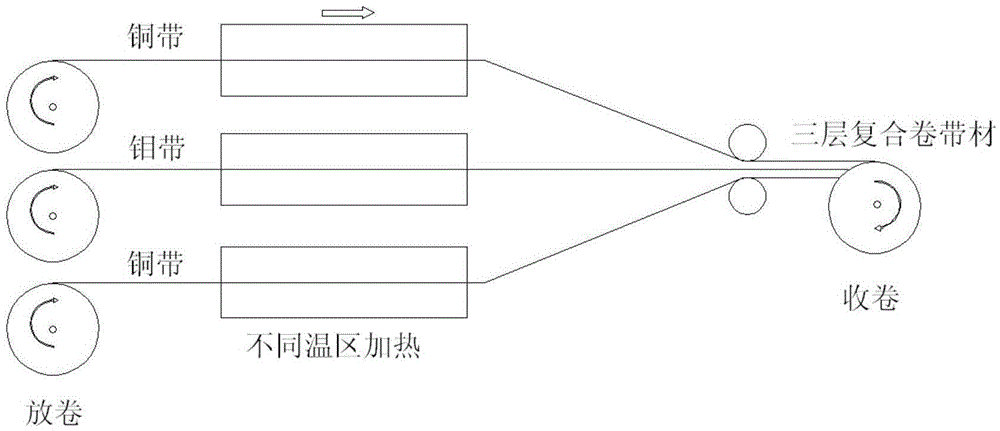

[0041] 2. Hot-rolling and compounding: Unwind the cleaned (Cu, Mo, Cu) three-metal coils and strips, and enter the corresponding heating temperature zones of the heating furnace respectively, Cu enters the 750°C heating temperature zone, and Mo enters the 950°C heating Temperature zone, at 10m 3 / h Under the protection of ammonia decomposition gas or hydrogen, enter the 100-ton rolling mill at the same time, with a deformation of 33%, rolling to a thickness of 2...

Embodiment 2

[0049] 1. Surface cleaning: unwind the copper (Cu) tape with a thickness of 0.7mm, and continuously degrease, pickle with 15% dilute sulfuric acid, and polish with a round scouring pad polishing sheet on the equipment with the function of rewinding and unwinding Rinse with pure water; molybdenum (Mo 70 Cu) Tape, unwinding, continuous degreasing, 20% acid pickling, round steel wire brush wheel polishing, and pure water washing on the equipment with winding and unwinding functions.

[0050] 2. Hot-rolled composite: the cleaned (Cu, Mo 70 Cu, Cu) three metal coils and strips are unwound, respectively enter the corresponding heating temperature zone of the heating furnace, Cu enters the 700 ° C heating temperature zone, Mo 70 Cu enters the 900°C heating temperature zone, at 10m 3 / h Under the protection of ammonia decomposition gas or hydrogen, enter the 100-ton rolling mill at the same time, with a deformation of 42%, rolling to a thickness of 1.4mm, and completing the three-me...

Embodiment 3

[0058] 1. Surface cleaning: unwind the copper (Cu) tape with a thickness of 0.1mm, and continuously degrease, pickle with 15% dilute sulfuric acid, and polish with a round scouring pad polishing sheet on the equipment with the function of rewinding and unwinding Rinse with pure water; molybdenum (Mo 60 Cu) Tape, unwinding, continuous degreasing, 20% acid pickling, round steel wire brush wheel polishing, and pure water washing on the equipment with winding and unwinding functions.

[0059] 2. Hot-rolled composite: the cleaned (Cu, Mo 60 Cu, Cu) three metal coils and strips are unwound, respectively enter the corresponding heating temperature zone of the heating furnace, Cu enters the 600 ℃ heating temperature zone, Mo 60 Cu enters the 800°C heating temperature zone, at 3m 3 / h Under the protection of ammonia decomposition gas or hydrogen, enter the 45-ton rolling mill at the same time, with a deformation of 30%, and roll to a thickness of 0.4mm. At a rolling speed of 10m / min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com