Method and system for manufacturing a three-dimensional object by means of additive manufacturing

A three-dimensional object and additive manufacturing technology, applied in the field of dispensing heads, can solve difficult and highly complex grid or honeycomb structures, and achieve the effects of time saving, high system integration, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

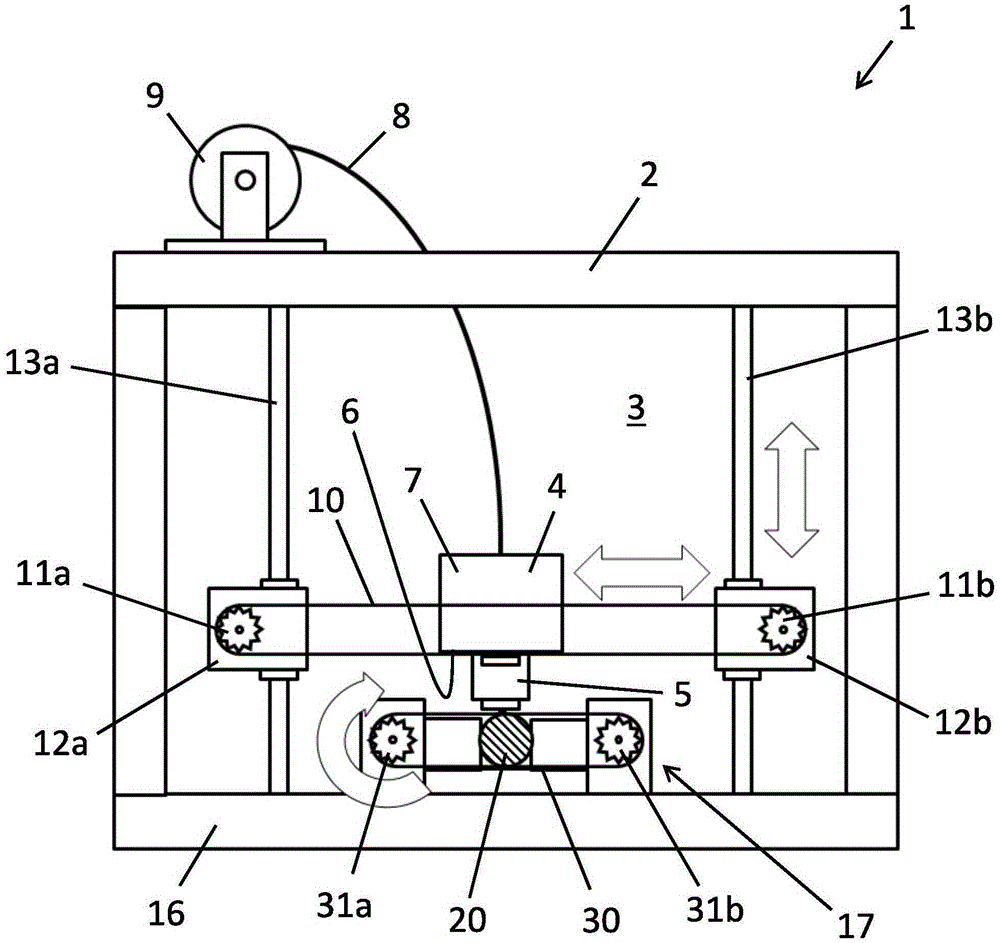

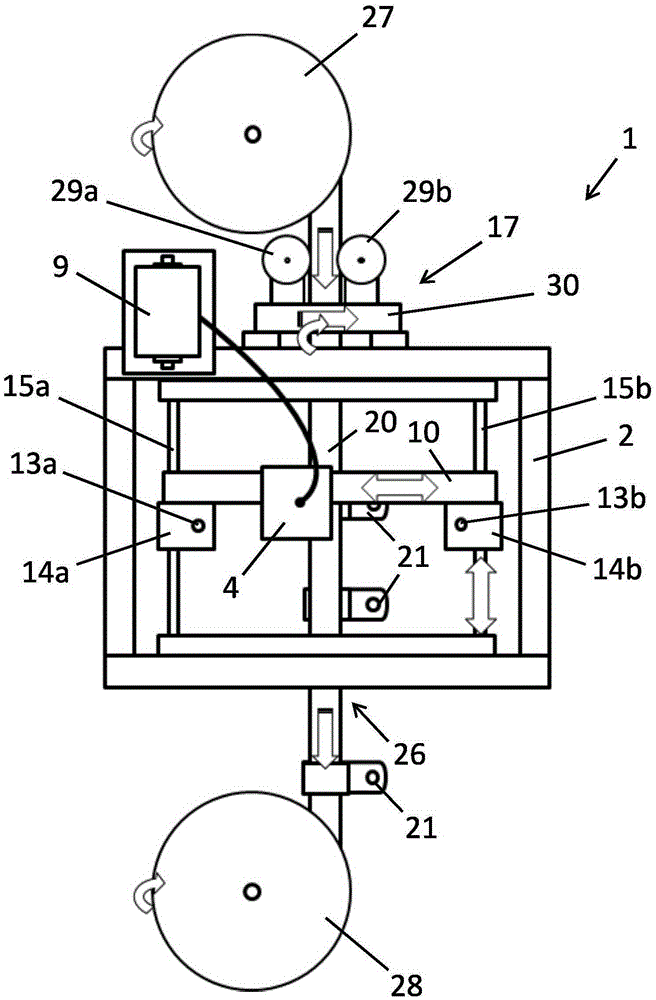

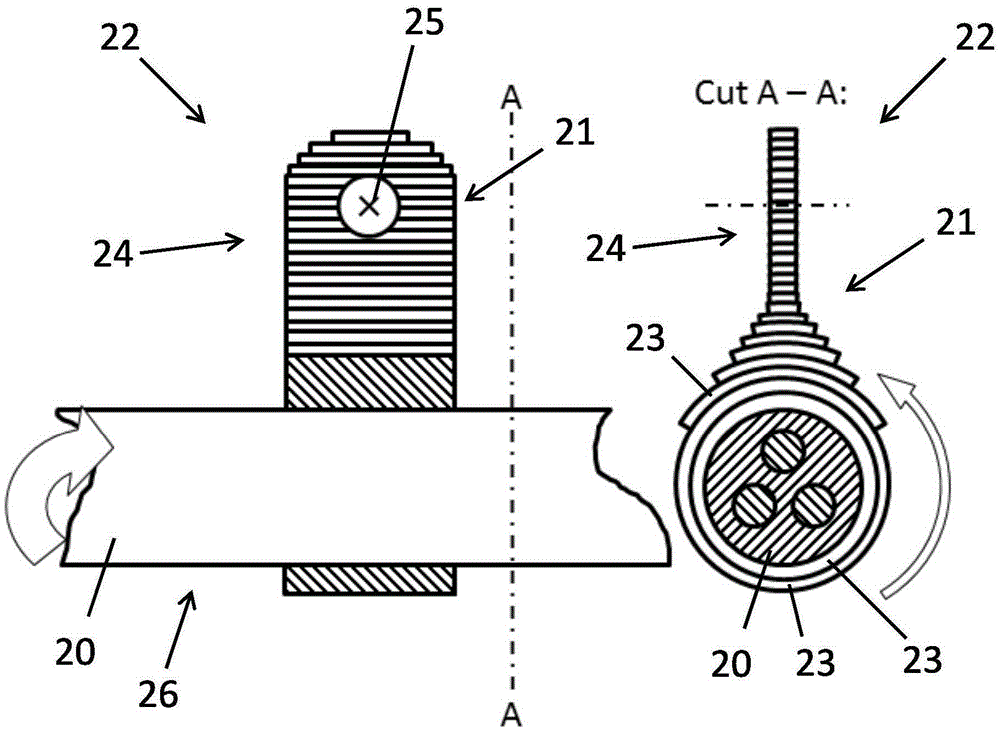

[0037] exist Figure 1a with 1b The system 1 shown in the figure comprises a system or machine frame 2 defining an interior space 3 within which a dispensing head 4 is movably supported. The dispensing head 4 comprises a nozzle 5 protruding from a rectangular surface 7 of a body 7 of the dispensing head. Inside the body 7, heating means (not shown) are provided for heating the thermoplastic material 8 above the glass transition temperature. The material 8 is supplied to the dispensing head 4 in the form of a wire, which is wound onto and fed from a reel 9 fixed to the frame 2 . After heating above the glass transition temperature, the material 8 is extruded or dispensed from the nozzle 5 in a dispensing direction defined by the central axis of the nozzle 5 or the nozzle opening of the nozzle 5 .

[0038] The distribution head 4 is mounted to the distribution head mounting structure. More specifically, via its body 7 the dispensing head 4 is mounted to an endless belt 10 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com