Medicinal residue paper as well as preparation method and application thereof

A medicine dregs and paper-based technology, applied in paper, papermaking, packaging paper, etc., can solve problems such as resource waste, environmental problems, and monotonous colors, and achieve the effects of increasing added value, improving market competitiveness, and solving monotonous colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

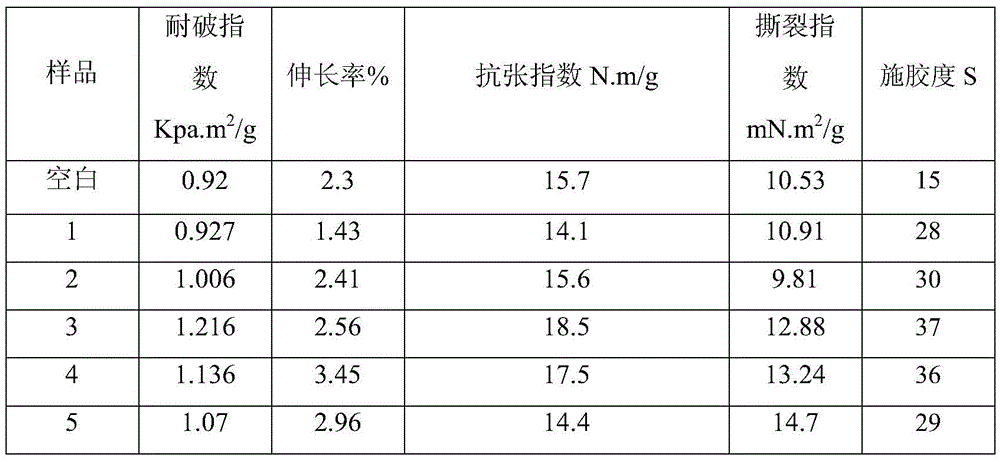

Examples

Embodiment 1

[0027] (1) Soak polyvinyl alcohol in cold water for 2 hours, and control the temperature at 10°C. Then dilute to a mass concentration of 7.0%, stir at a speed of 400r / min, heat the steam to 90°C for boiling, keep it warm for 1 hour, add water to dilute to a mass concentration of 2.0%, and keep warm at 70°C;

[0028] (2) Polyvinyl alcohol solution is made into sizing material, and the sizing material solid content is 1%, carries out sizing on paper machine surface sizing machine and obtains medicine residue paper, and sizing amount is 2g / m 2 , the basis weight of the paper is 80g / m 2 .

[0029] Composition ratio of pulp raw materials: 70% coniferous wood + 30% hardwood, controlled beating degree 40°SR, wet weight 4.3g.

Embodiment 2

[0031] (1) The ganoderma lucidum content is about 10% and the concentration is that the NaCl of 1% is soaked 20h stand-by for 20h; Then the processed medicinal residues are processed once with a thread rolling machine, and then the medicinal residues are passed through two stages of disc grinding ( The first refining gap is 1mm, and the second refining gap is 0.2mm). During the whole preparation process, the slurry concentration of the dregs is kept at 20% (referring to the ratio of ganoderma lucidum solid content to water), and stored for use.

[0032] (2) Soak polyvinyl alcohol in cold water for 2 hours, and control the temperature at 11°C. Then dilute to a mass concentration of 7.0%, stir at a speed of 400r / min, heat the steam to 90°C for boiling, keep it warm for 1 hour, add water to dilute to a mass concentration of 2.0%, and keep warm at 70°C;

[0033] (3) mixing sizing material relative to polyvinyl alcohol quality 5% drug residue slurry and polyvinyl alcohol solution,...

Embodiment 3

[0037] (1) The ganoderma lucidum content is about 20% medicinal dregs soak 21h stand-by with the NaCl concentration of 1.5%; Then the medicinal dregs after the treatment is processed once with a silk rolling machine, and the medicinal dregs are passed through two stages of disc grinding ( The first refining gap is 1.2mm, and the second refining gap is 0.4mm). During the whole preparation process, the slurry concentration of the dregs is kept at 25% (referring to the ratio of ganoderma lucidum solid content to water), and stored for later use.

[0038] (2) Soak polyvinyl alcohol in cold water for 4 hours, and control the temperature at 12°C. Then dilute to 7.0% concentration, stir at 600r / min, heat up steam to 95°C for boiling, keep warm for 2 hours, add water to dilute to 2.5% concentration, and keep warm at 75°C.

[0039] (3) mixing 10% drug residue slurry and polyvinyl alcohol solution with respect to the polyvinyl alcohol quality to form a sizing material, the sizing mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com