Drying device for spinning

A technology of drying device and working chamber, which is applied in the direction of textile material equipment configuration, spray/jet textile material treatment, liquid/gas/steam removal by air jet method, etc. It can solve the problems of reducing the quality of textiles and easy breeding of bacteria, etc. Achieve the effect of improving disinfection effect, good promotion and utilization value, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

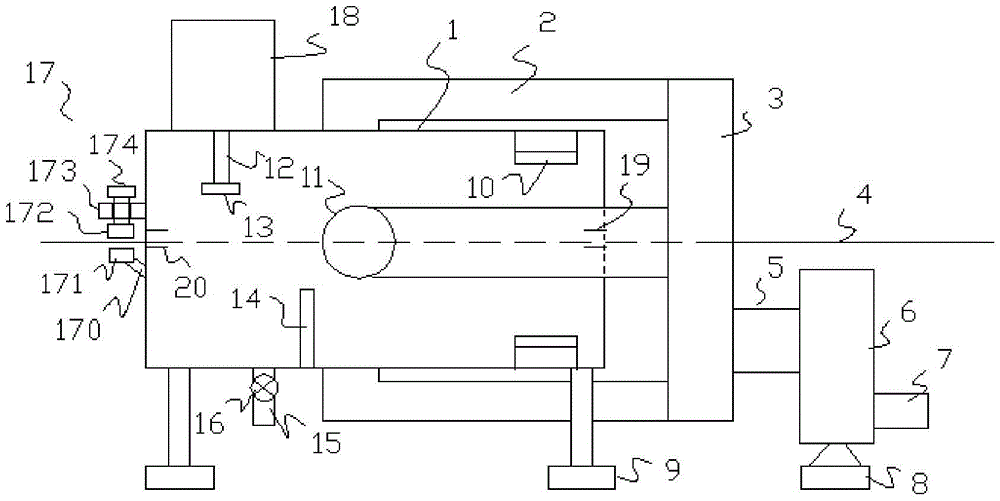

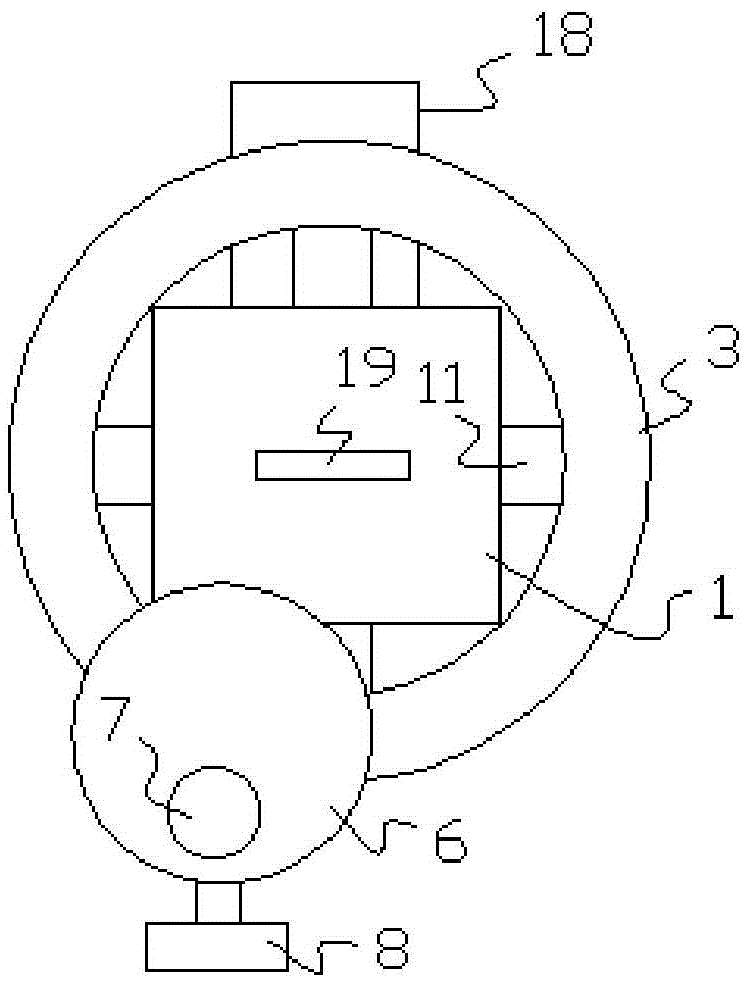

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0024] Such as figure 1 , figure 2 As shown, the structure of this drying device for textiles includes an airtight working chamber 1, the working chamber 1 is in the shape of a cuboid as a whole, and the left and right sides of the working chamber 1 are respectively provided with a feed port 20 and a discharge port 19, and the rest The four side walls are respectively provided with a blowing port 11, and the described blowing port 11 is connected with an annular connecting pipe 3 through the blowing pipe 2 respectively, and the annular connecting pipe 3 is connected with the air outlet 5 of the blower 6, and the blower 6 The outside is provided with air inlet 7. When in use, the device can simultaneously dry the textiles 4 in four wind directions, which increases the drying efficiency and improves the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com