A high-speed single crystal growth device and method

A growth method, single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., to achieve the effects of increasing the pulling speed, increasing the axial temperature gradient, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

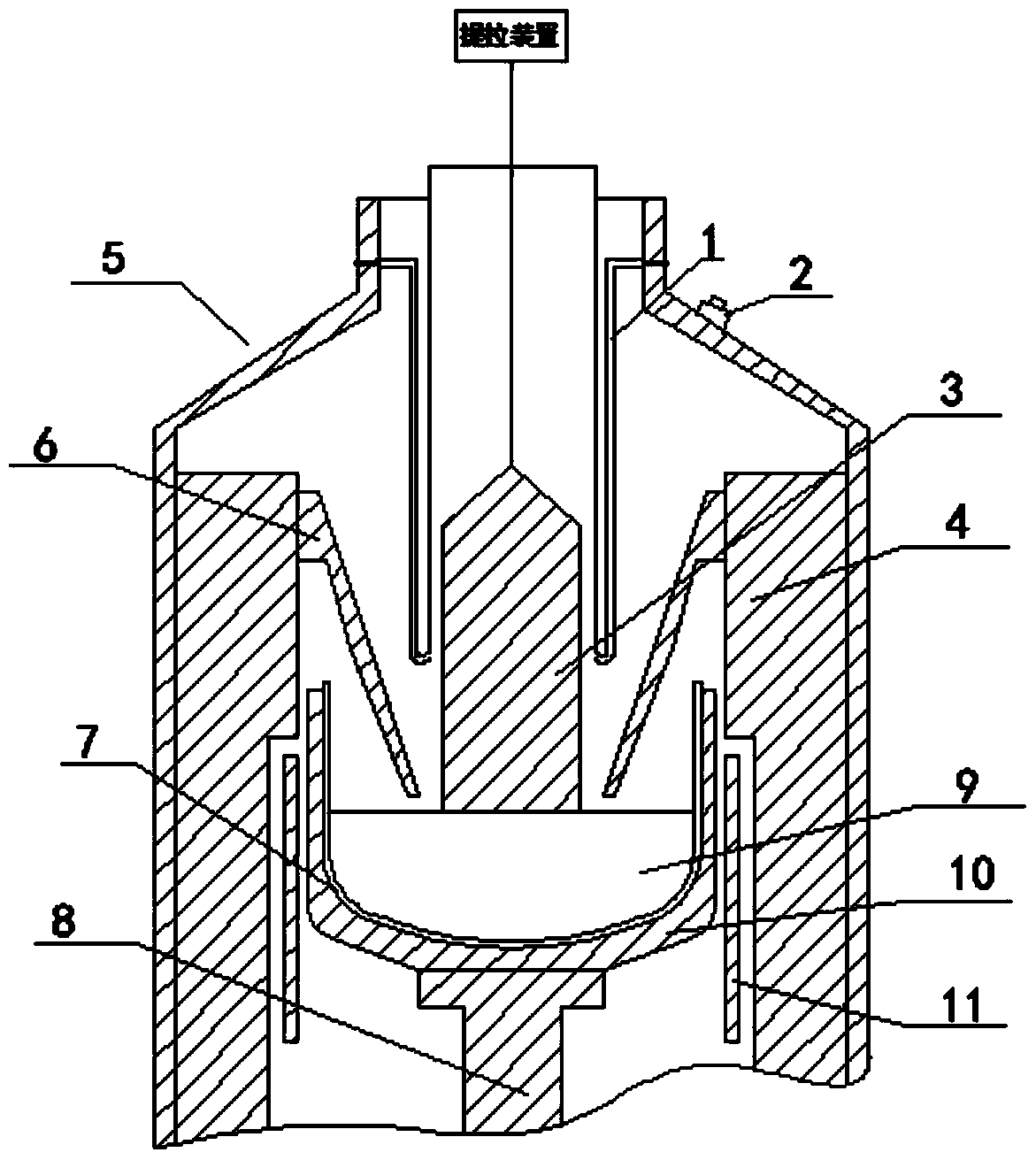

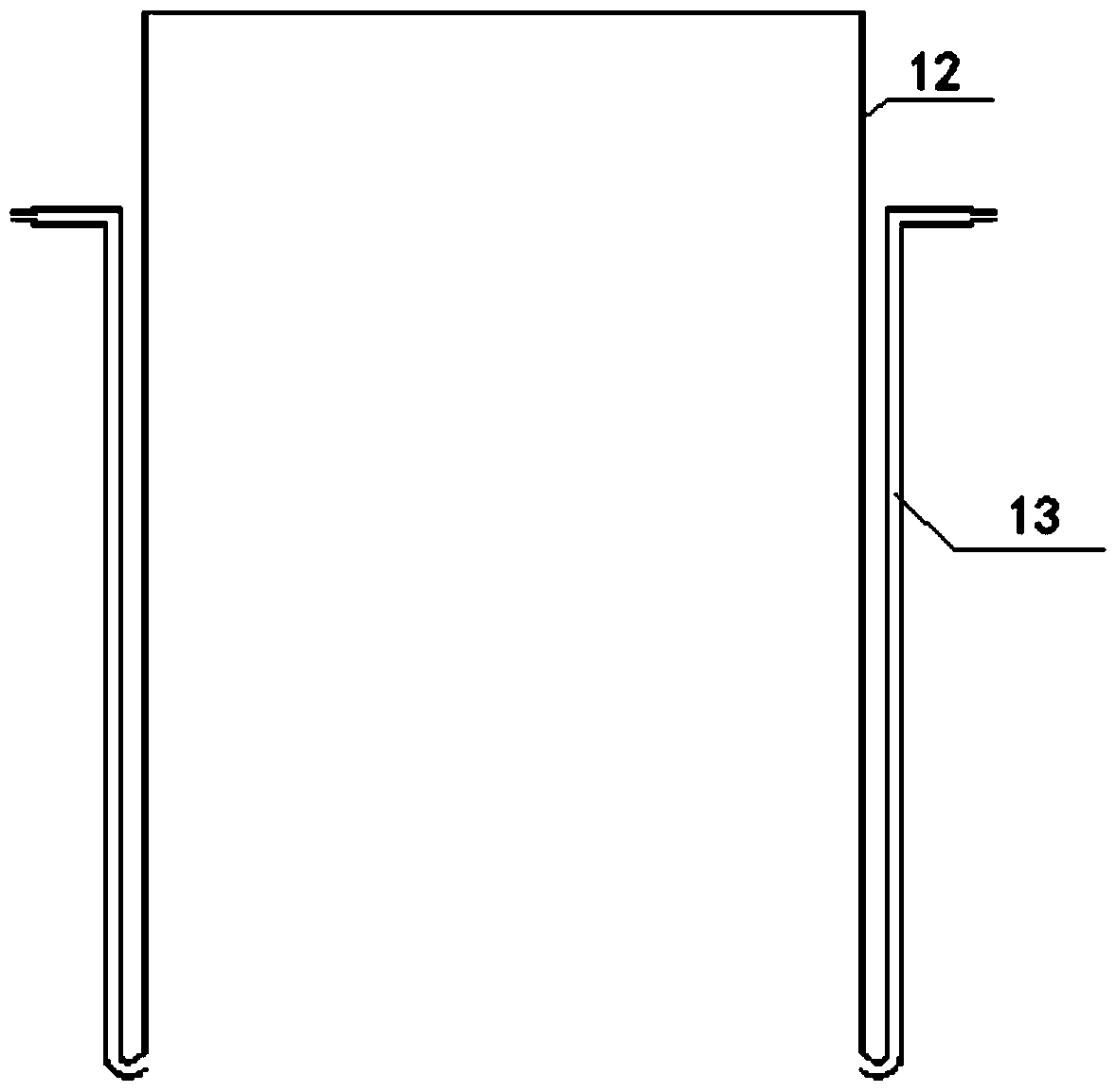

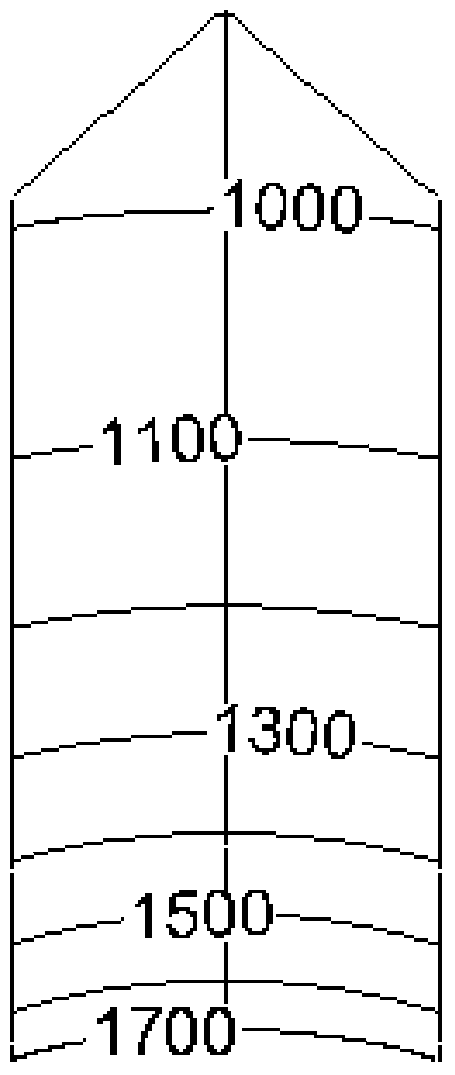

[0038] Such as figure 1 and figure 2 As shown, the high-speed single crystal growth device of the present invention includes a reaction cylinder 1, a CCD image sensor window 2, a crystal 3, an insulation cylinder 4, a furnace wall 5, a heat shield 6, a quartz crucible 7, a support body 8, a melt 9, graphite Crucible 10 and graphite heater 11. The support body 8 is used to support the graphite crucible and rotates. The outer side of the quartz crucible 7 and the graphite crucible 10 is a graphite heater 11, and the outer side of the graphite heater 11 is an insulating cylinder 4 for preventing heat loss; a heat shield 6 for diversion and heat preservation is arranged above the solution. The crystallization radius change of the crystal during the crystal growth process is monitored through the CCD image sensor window 2, and then the crystal pulling speed an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com