Iron-nitrogen-doped titanium dioxide-loaded carbon fiber composite photocatalyst and preparation method thereof

A technology of titanium dioxide and carbon fiber, which is applied in the field of photocatalysis, can solve the problems of difficult recycling of powdered materials, wide band gap, and low photon quantum efficiency, and achieve the effect of low cost, easy realization of conditions, and improvement of quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

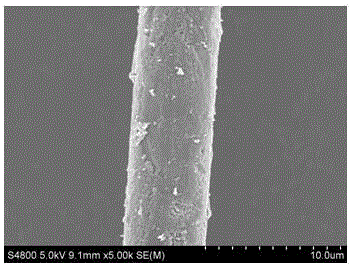

Image

Examples

Embodiment 1

[0032] Add 19mL of butyl titanate to 30mL of absolute ethanol, stir for 1h, and mix well to prepare solution A; add 0.02g of Fe(NO 3 ) 3 ?9H 2 O and 0.25g of urea were added to 2mL of acetic acid to prepare solution B; slowly add solution B to solution A under stirring conditions, and continue stirring for 1 hour to obtain solution C; 5.0mL of acetic acid and 6.2mL of absolute ethanol were added Add solution D to 3-4mL deionized water; slowly add solution D to solution C under stirring conditions, and continue stirring for 2.5 hours to obtain iron and nitrogen titanium dioxide precursor gel;

[0033] In order to improve the TiO 2 The load rate and load fastness on the carbon fiber surface, the carbon fiber surface is pretreated as follows:

[0034] Cut the carbon fibers into 5.0cm / bundle (0.1g / bundle), put 20 bundles into a round bottom flask, reflux with acetone at 60°C for 45min, wash with deionized water, and dry in the air. Then add 200mL of nitric acid with a concentr...

Embodiment 2

[0037] Add 19mL of butyl titanate to 30mL of absolute ethanol, stir for 1h, and mix well to prepare solution A; add 0.025g of Fe(NO 3 ) 3 ?9H 2 O and 0.1026g of urea were added to 2mL of acetic acid to prepare solution B; slowly add solution B to solution A under stirring conditions, and continue stirring for 1 hour to obtain solution C; 5.0mL of acetic acid and 6.2mL of absolute ethanol were added Add solution D to 3-4mL deionized water; slowly add solution D to solution C under stirring conditions, and continue stirring for 2.5 hours to obtain iron and nitrogen titanium dioxide precursor gel;

[0038] In order to improve the TiO 2 The load rate and load fastness on the carbon fiber surface, the carbon fiber surface is pretreated as follows:

[0039] Cut the carbon fibers into 5.0cm / bundle (0.1g / bundle), put 20 bundles into a round bottom flask, reflux with acetone at 60°C for 45min, wash with deionized water, and dry in the air. Then add 200mL of nitric acid with a conce...

Embodiment 3

[0042] Add 19mL of butyl titanate to 30mL of absolute ethanol, stir for 1h, and mix well to prepare solution A; add 0.03g of Fe(NO 3 ) 3 ?9H 2O and 0.1539g of urea were added to 2mL of acetic acid to prepare solution B; slowly add solution B to solution A under stirring conditions, and continue stirring for 1 hour to obtain solution C; 5.0mL of acetic acid and 6.2mL of absolute ethanol were added Add solution D to 3-4mL deionized water; slowly add solution D to solution C under stirring conditions, and continue stirring for 2.5 hours to obtain iron and nitrogen titanium dioxide precursor gel;

[0043] In order to improve the TiO 2 The load rate and load fastness on the carbon fiber surface, the carbon fiber surface is pretreated as follows:

[0044] Cut the carbon fibers into 5.0cm / bundle (0.1g / bundle), put 20 bundles into a round bottom flask, reflux with acetone at 60°C for 45min, wash with deionized water, and dry in the air. Then add 200mL of nitric acid with a concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com