Linear composite gel fragrance controlled-release filter stick and preparation method and application thereof

A composite gel and filter rod technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve the problems of easy volatilization of aroma substances, low adsorption of aroma substances, and uncomfortable activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

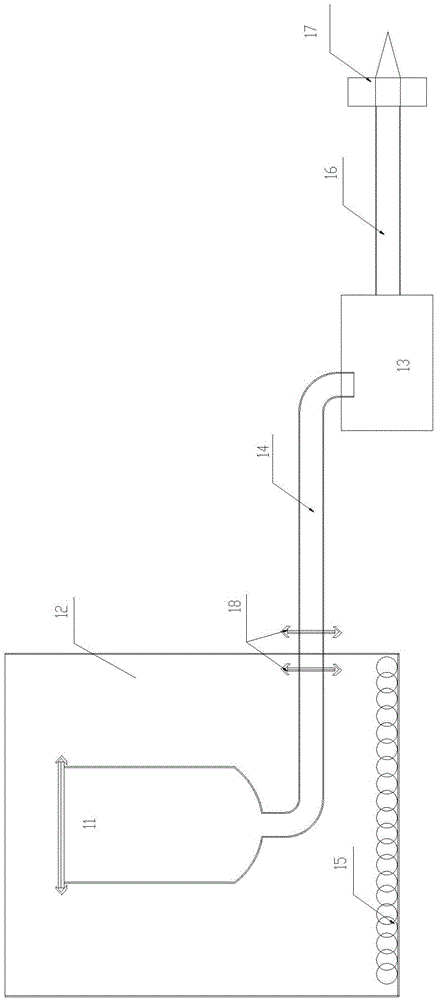

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Preparation of linear composite gel fragrance sustained-release filter stick

[0066] The implementation steps of this embodiment are as follows:

[0067] A. Prepare the mixture solution

[0068] Add excess chitosan, sodium carboxymethyl cellulose, modified starch and β-cyclodextrin to water respectively, heat and stir at 60°C for 0.4h, then let it cool, and the supernatants are chitosan Saturated solutions of sugar, sodium carboxymethylcellulose, modified starch and β-cyclodextrin; then, these saturated solutions were mixed with an aqueous solution of 0.04% by weight of sodium citrate in the same volume to obtain a a mixture solution;

[0069] B. Preparation of composite gel

[0070] Heat the polyethylene glycol to a temperature of 55°C to make it completely melted, and then mix the molten polyethylene glycol with the mixture solution obtained in step A uniformly at a weight ratio of 1:1 to obtain a composite gel;

[0071] C. Add spices

[0072] Add men...

Embodiment 2

[0079] Embodiment 2: the preparation of linear composite gel fragrance sustained-release filter stick

[0080] The implementation steps of this embodiment are as follows:

[0081] A. Prepare the mixture solution

[0082] Add excess chitosan, sodium carboxymethyl cellulose, modified starch and β-cyclodextrin to water respectively, heat and stir at 58°C for 0.6h, then let it cool, and the supernatants are respectively chitosan Saturated solutions of sugar, sodium carboxymethylcellulose, modified starch and β-cyclodextrin; then, these saturated solutions were mixed with an aqueous solution of 0.05% by weight of sodium citrate in the same volume to obtain a a mixture solution;

[0083] B. Preparation of composite gel

[0084] heating the polyethylene glycol to a temperature of 30°C to make it completely melted, and then mixing the molten polyethylene glycol with the mixture solution obtained in step A uniformly at a weight ratio of 10:1 to obtain a composite gel;

[0085] C. A...

Embodiment 3

[0088] Embodiment 3: the preparation of thread-shaped composite gel fragrance slow-release filter stick

[0089] The implementation steps of this embodiment are as follows:

[0090] A. Prepare the mixture solution

[0091] Add excess chitosan, sodium carboxymethyl cellulose, modified starch and β-cyclodextrin to water respectively, heat and stir at 62°C for 0.5h, then leave to cool, and the supernatants are respectively chitosan Saturated solutions of sugar, sodium carboxymethylcellulose, modified starch and β-cyclodextrin; then, these saturated solutions were mixed with an aqueous solution of 0.06% by weight of sodium citrate in the same volume to obtain a a mixture solution;

[0092] B. Preparation of composite gel

[0093] Heat the polyethylene glycol to a temperature of 80°C to completely melt it, then mix the molten polyethylene glycol with the mixture solution obtained in step A uniformly at a weight ratio of 5:1 to obtain a composite gel;

[0094] C. Add spices

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com