Catalytic hydrogenation method for inferior wax oil

A low-quality wax oil, catalytic hydrogenation technology, applied in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of harsh reaction conditions, high hydrogen consumption and energy consumption, fast carbon deposition rate, etc. The effect of reducing density, reducing emission of flue gas pollutants, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0047] According to a preferred embodiment of the present invention, the method of the present invention comprises:

[0048] (1) In the presence of hydrogen, the inferior wax oil is introduced into the first reaction zone to carry out the first hydrorefining;

[0049] (2) The effluent of the first reaction zone is introduced into the flash section for flash evaporation to obtain gas phase components and liquid phase components;

[0050] (3) introducing the liquid phase components into the second reaction zone and contacting with the hydrogen gas introduced from the bottom of the second reaction zone in countercurrent to carry out the second hydrofinishing;

[0051] (4) introducing the gas-liquid separation system after mixing the effluent from the second reaction zone with the gas phase components obtained in step (2), to obtain hydrogen-rich gas and liquid phase stream;

[0052] (5) introducing the hydrogen-rich gas into a circulating hydrogen desulfurization system for desu...

Embodiment 1

[0064] In this example, a high-sulfur vacuum wax oil fraction from the Middle East is used as the raw material of inferior wax oil, its properties are shown in Table 1, and the reaction conditions are shown in Table 2. The first reaction zone is filled with supported CoMo catalyst RVS-420, and the second reaction zone is filled with Supported catalyst RN-32V.

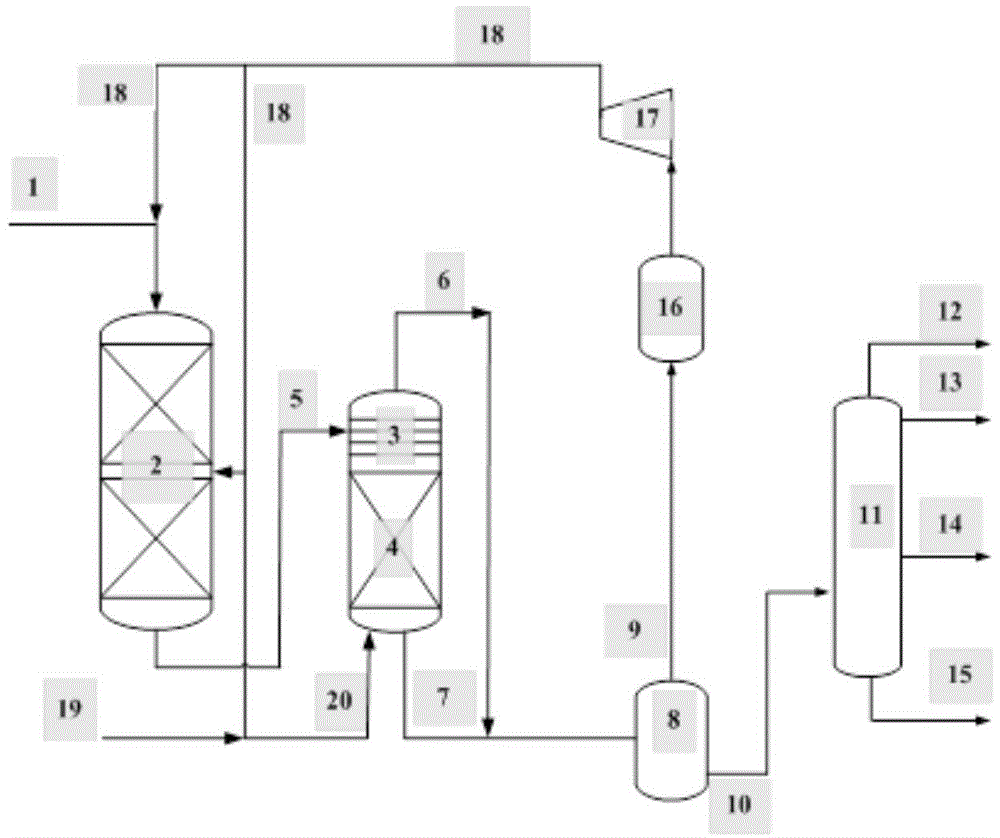

[0065] according to the invention figure 1 The process schematic diagram shown is carried out, specifically:

[0066] Inferior wax oil 1 and circulating hydrogen 18 are mixed and enter the first reaction zone 2 through a heat exchanger (not shown) and a heating furnace (not shown), and the first reaction zone effluent 5 enters the flash section 3, and flashes out The gas phase component 6, the liquid phase component enters the second reaction zone 4, and the hydrogen gas 20 formed by mixing the fresh hydrogen gas 19 and the recycled hydrogen 18 enters from the bottom of the second reaction zone 4, and the liquid phase ...

Embodiment 2

[0090] In this example, a mixture of high-sulfur vacuum gas oil fraction and coker gas oil in the Middle East is used as the raw material of low-quality wax oil, and its properties are shown in Table 1. The first reaction zone is filled with RN-32V, and the second reaction zone is filled with non-loaded gas oil. Hydrogen Refining Catalyst .

[0091] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0092] The reaction conditions are shown in Table 4.

[0093] All the other are identical with embodiment 1.

[0094] The properties of the resulting product are shown in Table 5.

[0095] Table 4

[0096] Process conditions

[0097] table 5

[0098] Product properties of refined wax oil

[0099] As can be seen from the data in Table 4 and Table 5, under mild reaction conditions, the sulfur content can be reduced from 13000 μg / g in the raw material to 469 μg / g in the refined wax oil product by adopting the metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com