Breathable fresh-keeping film with degrading capability and preparation method of breathable fresh-keeping film

A technology of fresh-keeping film and capacity, applied in the field of breathable fresh-keeping film and its preparation, can solve the problems of PE fruit and vegetable fresh-keeping film, such as non-degradable, fruit and vegetable spoilage, environmental pollution, etc., to prolong the fresh-keeping time of fruits and vegetables, solve non-degradable, good water permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

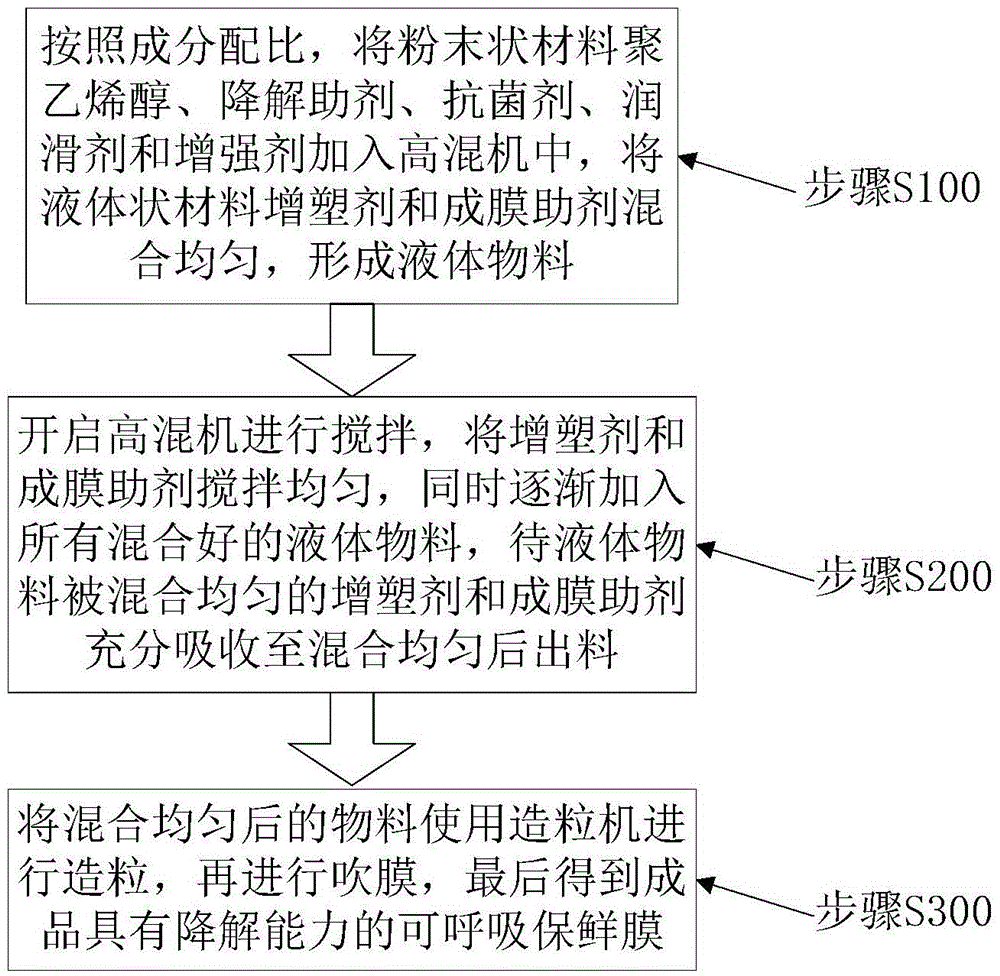

[0048] Such as figure 1 Shown, a kind of preparation method of breathable fresh-keeping film with degradability as described above, specifically comprises the following steps:

[0049] Step S100: Add polyvinyl alcohol, degradation aids, antibacterial agents, lubricants and reinforcing agents (powder materials) into the high mixer according to the composition ratio, and add plasticizers and film-forming aids (liquid materials) Mix well to form a liquid material;

[0050] Step S200: Turn on the high-mixer for stirring, stir the plasticizer and film-forming aid evenly, and gradually add all the mixed liquid materials at the same time, until the liquid material is fully absorbed by the uniformly mixed plasticizer and film-forming aid Discharge after mixing evenly;

[0051] Step S300: Use a granulator to granulate the uniformly mixed materials, and then blow the film, and finally obtain a breathable fresh-keeping film with degradable finished product.

[0052] Specifically, in t...

Embodiment 1

[0058] The degradable breathable fresh-keeping film includes: PVA-1199: 20 parts, PVA-2099: 50 parts, tapioca starch: 30 parts, glycerol: 15 parts, and polyethylene glycol: 5 parts by weight. Parts, sodium dodecylbenzenesulfonate: 1 part, titanium dioxide: 1 part, water: 30 parts, potassium sorbate: 1 part.

[0059] Preparation method: put PVA-1199: 20 parts, PVA-2099: 50 parts, tapioca starch: 30 parts, sodium dodecylpicrine sulfonate: 1 part, titanium dioxide: 1 part and potassium sorbate: 1 part, put into Mix evenly in the high mixer; mix glycerol: 15 parts, polyethylene glycol: 5 parts and water: 30 parts evenly, then add them to the high mixer and mix them with powder materials evenly, then discharge, use a granulator to mix The homogenized material is granulated in the range of 160-180°C, and then blown into a film using a film blowing machine at a suitable temperature of 160-180°C.

Embodiment 2

[0061] The degradable breathable plastic wrap includes: PVA-1799: 90 parts, potato starch: 10 parts, glycerol: 40 parts, polyethylene glycol: 10 parts, sorbic acid: 0.5 parts , potassium lauryl polyether sulfate: 1 part, silicon dioxide: 15 parts, water: 5 parts.

[0062] Preparation method: put PVA-1799: 90 parts, potato starch: 10 parts, sorbic acid: 0.5 parts, lauryl polyether potassium sulfate: 1 part and silicon dioxide: 15 parts, put them into a high mixer and mix them evenly; Glycerol: 40 parts, Polyethylene Glycol: 10 parts and Water: 5 parts are mixed evenly and then added to the high mixer and mixed with powder materials evenly before discharging. The granulation is carried out within the range of 160-180°C, and then blown into a film using a film blowing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com