Environmentally friendly heat stabilizer for pvc cables prepared from waste polyester and preparation method thereof

A technology of heat stabilizer and waste polyester, applied in the field of environmental protection heat stabilizer and its preparation, can solve the problems of hidden danger of human body and environment, high price, strong water absorption, etc., to improve the safety of use and stabilize the volume resistivity , the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

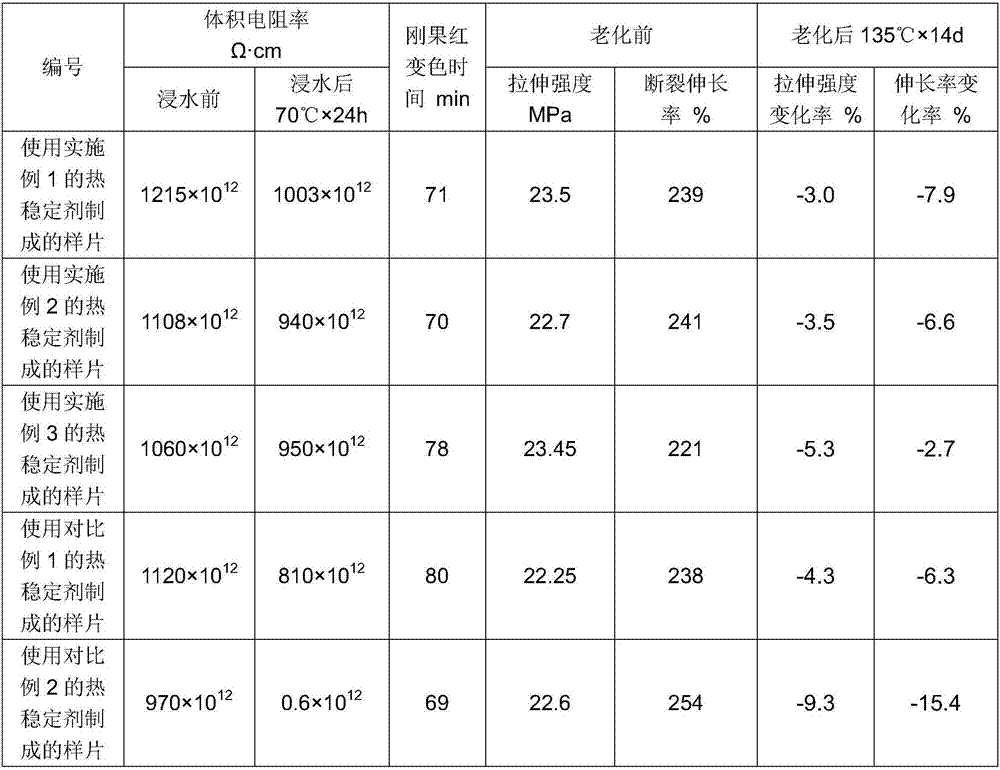

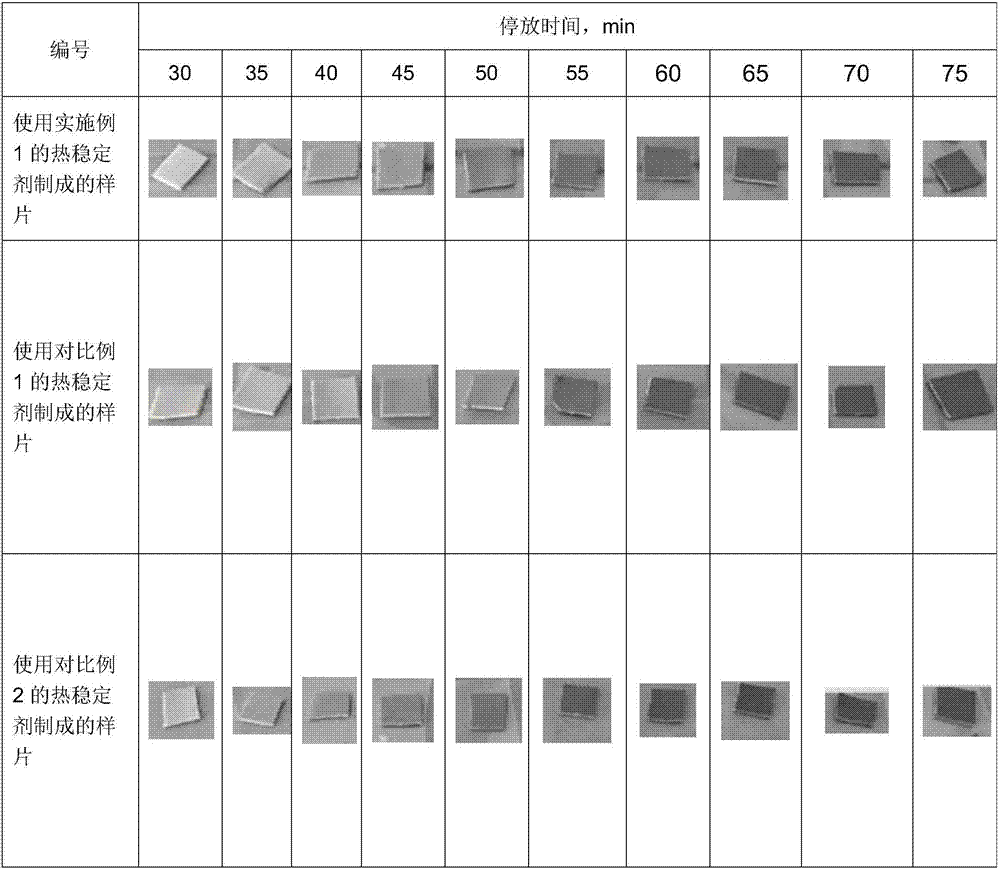

Examples

preparation example Construction

[0022] A kind of preparation method of the special environment-friendly heat stabilizer of PVC cable that waste polyester is prepared is characterized in that the specific steps of preparation method are:

[0023] (1) Under constant stirring, add terephthalic acid into the sodium hydroxide solution with a concentration of 2% to 7% according to the stoichiometric relationship. After the terephthalic acid is completely dissolved, add 0.5 % activated carbon, stirred for 10min to make it evenly dispersed in the solution, and then filtered to obtain a decolorized sodium terephthalate clarified solution;

[0024] (2) Under continuous stirring, add the mixed solution of calcium chloride solution and zinc chloride solution configured in advance in the sodium terephthalate clarified solution obtained in step (1), and continue at a speed of 100 to 800r / min Stir and react for 20-120 minutes to obtain a mixed system of calcium terephthalate and zinc terephthalate;

[0025] (3) Under cons...

Embodiment 1

[0033] The special environment-friendly heat stabilizer for PVC cable prepared by waste polyester comprises the following components by weight:

[0034] Calcium Stearate 15%, Zinc Stearate 15%, Calcium Terephthalate 35%, Zinc Terephthalate 18%, Calcium Hydroxide 10%, Beta-Diketone 2%, Antioxidant 2246 5% .

[0035] A kind of preparation method of the special environment-friendly heat stabilizer of PVC cable that waste polyester is prepared is characterized in that the specific steps of preparation method are:

[0036](1) Under constant stirring, add terephthalic acid into a sodium hydroxide solution with a concentration of 2% according to the stoichiometric relationship, and after the terephthalic acid is completely dissolved, add activated carbon that accounts for 0.5% by mass of the solution , stirred for 10 minutes to make it uniformly dispersed in the solution, and then filtered to obtain a decolorized sodium terephthalate clarified solution;

[0037] (2) under constant ...

Embodiment 2

[0046] The special environment-friendly heat stabilizer for PVC cable prepared by waste polyester comprises the following components by weight:

[0047] Calcium stearate 25%, zinc stearate 25%, calcium terephthalate 15%, zinc terephthalate 30%, calcium hydroxide 3.5%, β-diketone 0.5%, antioxidant (antioxidant The mass percentage of 2246 and antioxidant DLTP is 3:1) 1%.

[0048] A kind of preparation method of the special environment-friendly heat stabilizer of PVC cable that waste polyester is prepared is characterized in that the specific steps of preparation method are:

[0049] (1) Under constant stirring, add terephthalic acid into the sodium hydroxide solution with a concentration of 7% according to the stoichiometric relationship, and after the terephthalic acid is completely dissolved, add activated carbon that accounts for 0.5% by mass of the solution , stirred for 10 minutes to make it uniformly dispersed in the solution, and then filtered to obtain a decolorized sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com