Method of preparing glycol dimethyl ether through continuous etherification in fixed bed

A technology of ethylene glycol dimethyl ether and fixed bed, which is applied in the fields of ether preparation, dehydration of hydroxyl-containing compounds to prepare ether, organic chemistry, etc., which can solve the problems of difficult post-processing, low diether selectivity, pollution, etc., and achieve reaction The process is green, the reaction process is simple, and the effect of reducing dependence on petroleum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

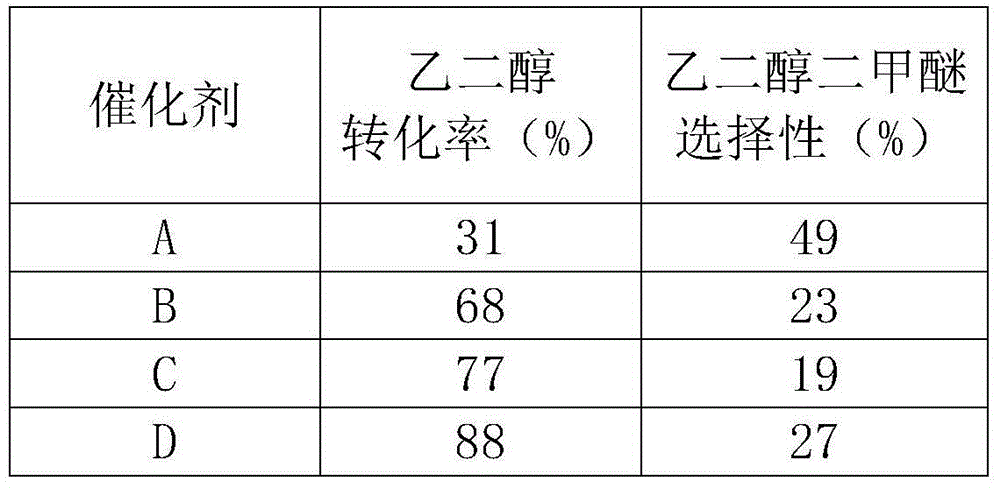

[0019] The test of embodiment 1 ethylene glycol and methanol etherification reaction performance

[0020] The catalyst is loaded into the fixed bed reactor, and the reactor is installed in the fixed bed. Prepare ethylene glycol and methanol raw materials with a molar ratio of 0.2, and then pump them into a preheating premixer with a preheating temperature of 250°C. Introduce 40ml / min of nitrogen, control the reaction pressure to maintain around 0.5MPa, then pump the raw materials into the reactor, control the reaction temperature to 230°C, and the liquid space velocity to 1.5h -1 , After 2 hours of reaction, samples were taken for analysis. The catalyst evaluation results are shown in Table 1.

[0021] Table 1 ethylene glycol and methanolylation reaction results

[0022]

[0023]

Embodiment 2

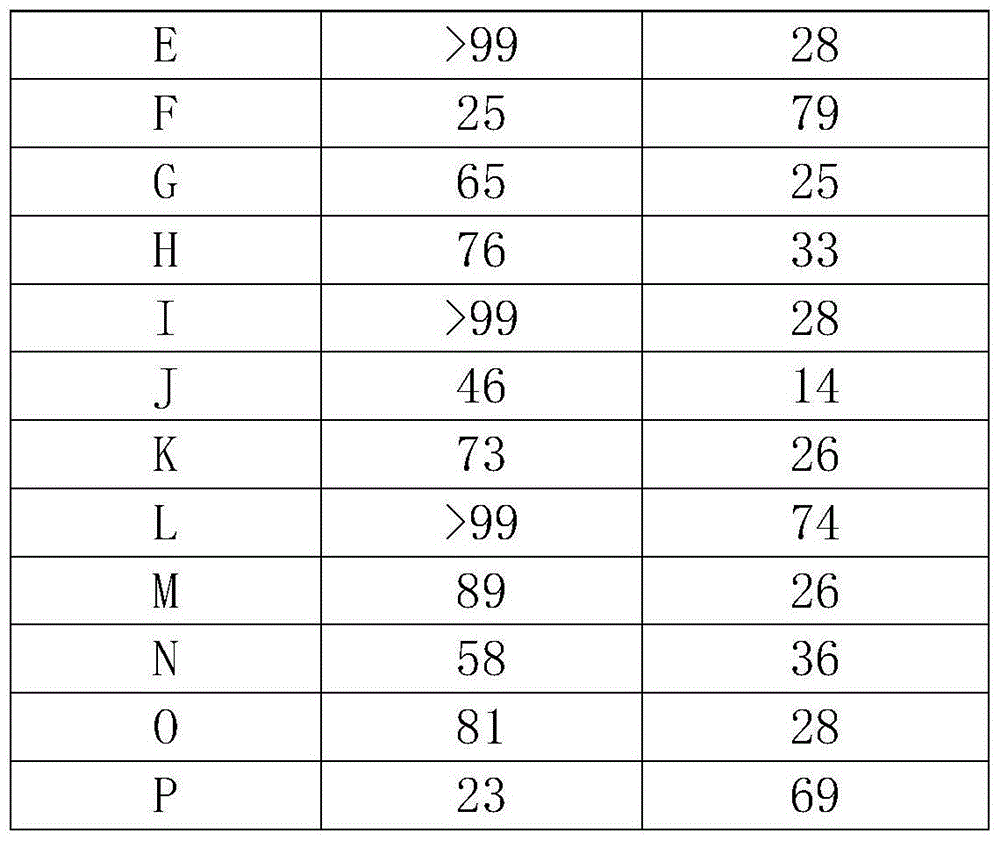

[0024] Embodiment 2 catalyst stability test

[0025] This example mainly investigates the catalyst stability in the etherification reaction of ethylene glycol and methanol. Choose L to be catalyst, experimental process is with embodiment 1, and the results are shown in Table 2.

[0026] Table 2 Catalyst stability test

[0027]

Embodiment 3

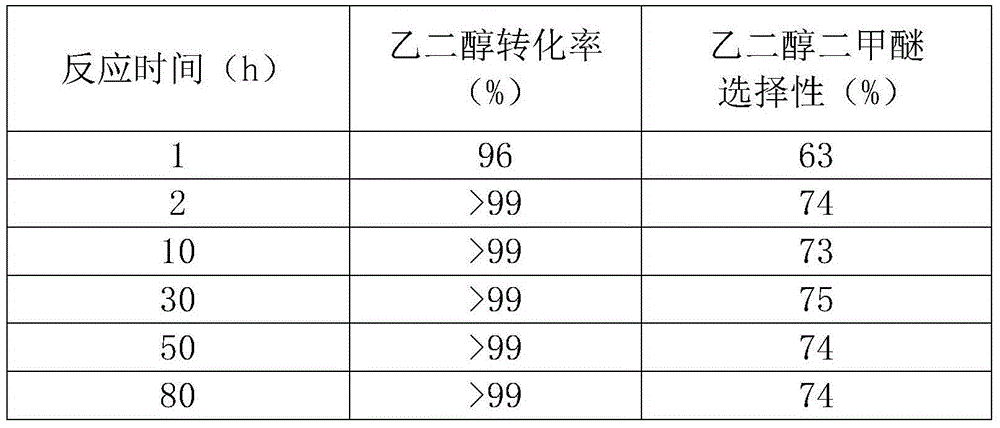

[0028] The influence of embodiment 3 reaction temperature on ethylene glycol etherification reaction

[0029] In this example, the influence of the reaction temperature on the result of the etherification reaction between ethylene glycol and methanol is studied, which is embodied in the conversion rate of ethylene glycol and the selectivity of ethylene glycol dimethyl ether. L catalyst was loaded into the fixed bed reactor. Prepare ethylene glycol and methanol raw materials with a molar ratio of 0.2, and then pump them into a preheating premixer with a preheating temperature of 250°C. Introduce 40ml / min of nitrogen, control the reaction pressure and maintain it at about 0.3MPa, then pump the raw materials into the reactor, and the liquid space velocity is 1.5h -1 , After 2 hours of reaction, samples were taken for analysis. The results are shown in Table 3.

[0030] The relation of table 3 reaction temperature and ethylene glycol etherification reaction result

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com