Printing technology for simulating cigarette package special paper effect

A special paper and process technology, applied in printing, printing post-processing, printing devices, etc., can solve the problems of excessive harmful substance content, prohibitive and other problems, and achieve the effect of high yield, strong contrast and rich layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

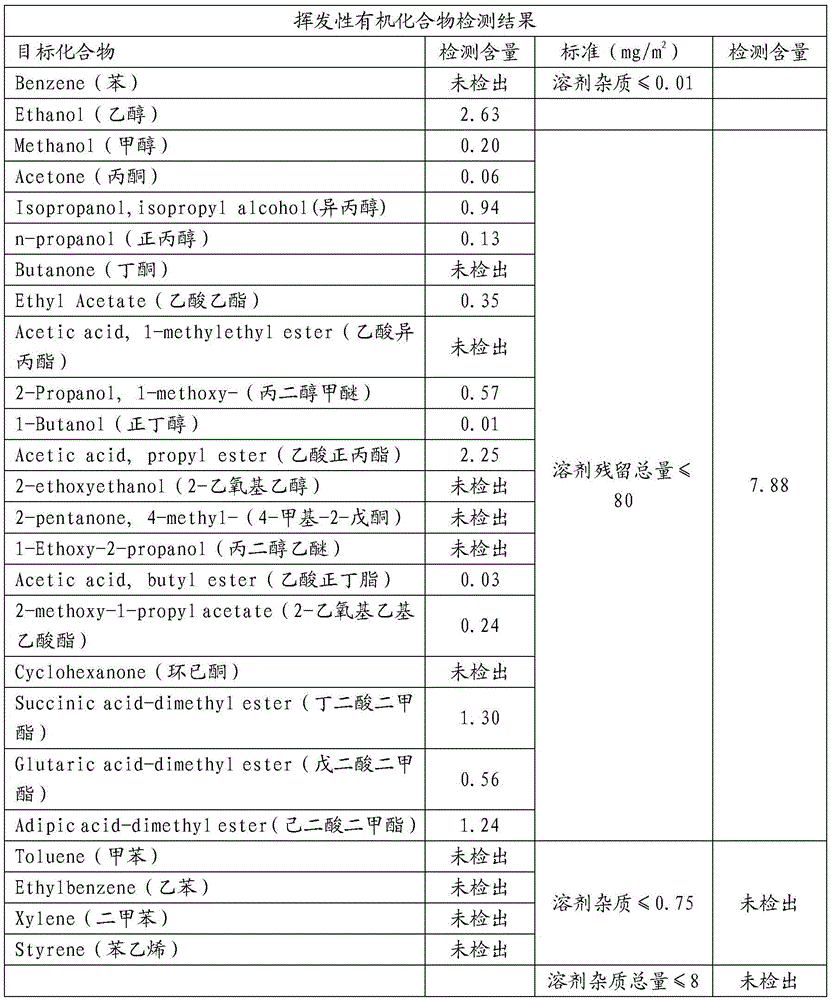

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be further described in detail below. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0018] Selection of paper: use materials such as glossy silver cards or laser silver cards with bright surfaces and flat surfaces that will not affect other graphic printing processes.

[0019] Offset printing: 6-color UV spot color printing, the bottom color should be highly transparent, smooth and pure during offset printing.

[0020] The first pass of silk screen marble ink: select transparent ink with high transparency, high concentration and good flexibility, and express it with extremely fine lines and uneven grain size graphics, and use 300-mesh screen printing to make the graphic performance both fine and sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com