Bi-metal pipeline and pipe fitting beveling method and bi-metal pipeline and pipe fitting assembly

A bimetallic pipe and pipe bevel technology, applied in the direction of pipes/pipe joints/fittings, metal processing equipment, pipes, etc., can solve the problems of reduced corrosion resistance of welds, changes in weld materials, and misalignment, etc., to avoid The effects of weld leakage, ensuring weld quality and pipeline operation safety, and avoiding serious problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

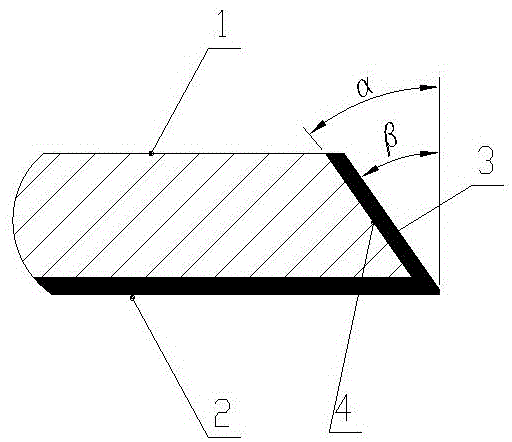

[0024] Such as figure 1 As shown, the bevel method for bimetallic pipes and pipe fittings of the present invention is used for bimetallic pipes and bimetallic pipe fittings. Both bimetallic pipes and bimetallic pipe fittings include a base layer 1 and a cladding layer 2. The material of the base layer 1 is carbon steel, alloy One of steel and stainless steel, the cladding layer 2 is made of nickel-based alloy or stainless steel,

[0025] Groove method:

[0026] In the first step, the first groove processing is performed on the base layer 1 and the layer 2 of the end face of the bimetallic pipe or bimetallic pipe fitting, and the degree α of the groove is 30-37.5 degrees;

[0027] In the second step, surfacing welding is performed on the processed groove end face 4 to form a surfacing layer, and the material of the surfacing layer is nickel-based alloy or stainless steel. The surfacing layer formed at this time is called the initial surfacing layer;

[0028] The third step i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com