Manufacturing method of high-strength bioactive porous scaffold

A bioactive, porous scaffold technology, applied in medical science, prosthesis, additive processing, etc., can solve problems such as difficult pore shape and size, low mechanical strength, and incomplete pore structure, and achieve good mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

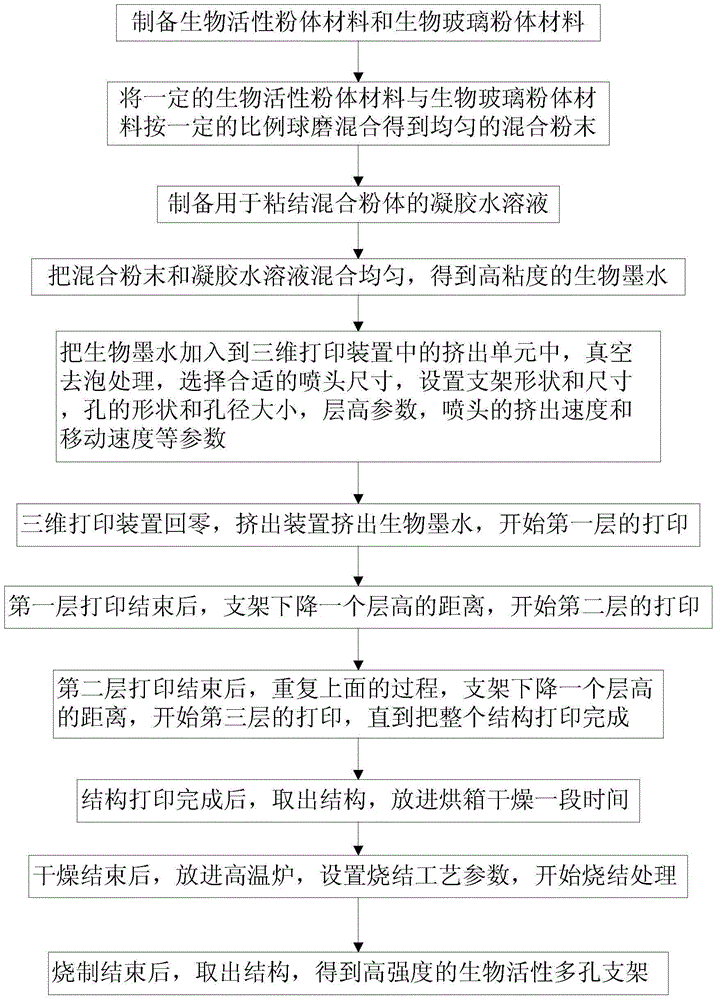

[0055] Such as figure 1 Shown is a flow chart of a high-strength bioactive porous scaffold manufacturing method of the present invention, and the specific implementation steps are as follows:

[0056] (1) Preparation of β-calcium silicate powder material and 45S5 bioglass powder material:

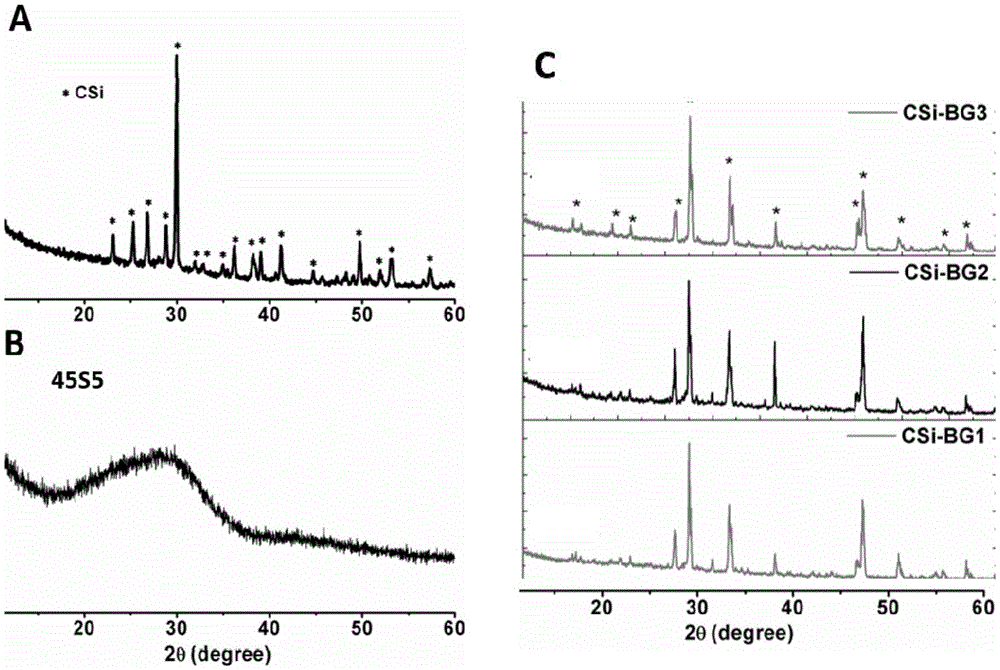

[0057] β-calcium silicate powder material: mix 1L of 0.5mol / LCa(NO 3 ) 2 The pH value of the aqueous solution was adjusted to 11.5, and then the solution was added dropwise to a volume of 1 L of 0.5mol / L Na 2 SiO 3 In the aqueous solution, continue to stir for 480 minutes after the dropwise addition, then filter the reaction sediment, wash with deionized water for 3 times, then wash with absolute ethanol for 3 times, dry at 80°C, and calcined at 950°C for 3 hours , and then ball milled for 5 hours to obtain β-calcium silicate powder with a particle size of 1 μm to 10 μm. After X-ray diffraction test, it is proved that the powder phase is pure β-calcium silicate, such as figure 2 Show...

Embodiment 2

[0072] Same as Example 1, the difference is that in step (5), the bio-ink in the extrusion unit is not subjected to vacuum defoaming treatment, and other conditions remain unchanged, and there are many micropores on the lines of the porous support obtained at last, such as Figure 8 As shown, its compressive strength is 16.1MPa, and the porosity is 65±1.5%, these micropores greatly reduce the strength of the scaffold.

Embodiment 3

[0074] Same as Example 1, the difference is that in step (11), the sintering temperature of the scaffold structure is changed to 1000° C. for 4 hours, and other conditions remain unchanged. The compressive strength of the obtained porous scaffold is 13.2 MPa, and the porosity is 68.2 ± 0.8%, observed under the scanning electron microscope, its section is not dense enough, there are many micropores, such as Figure 9 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com