Thin film transistor array and image display device

A technology of thin film transistors and arrays, applied in the field of thin film transistor arrays and image display devices, capable of solving problems such as production volume or cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

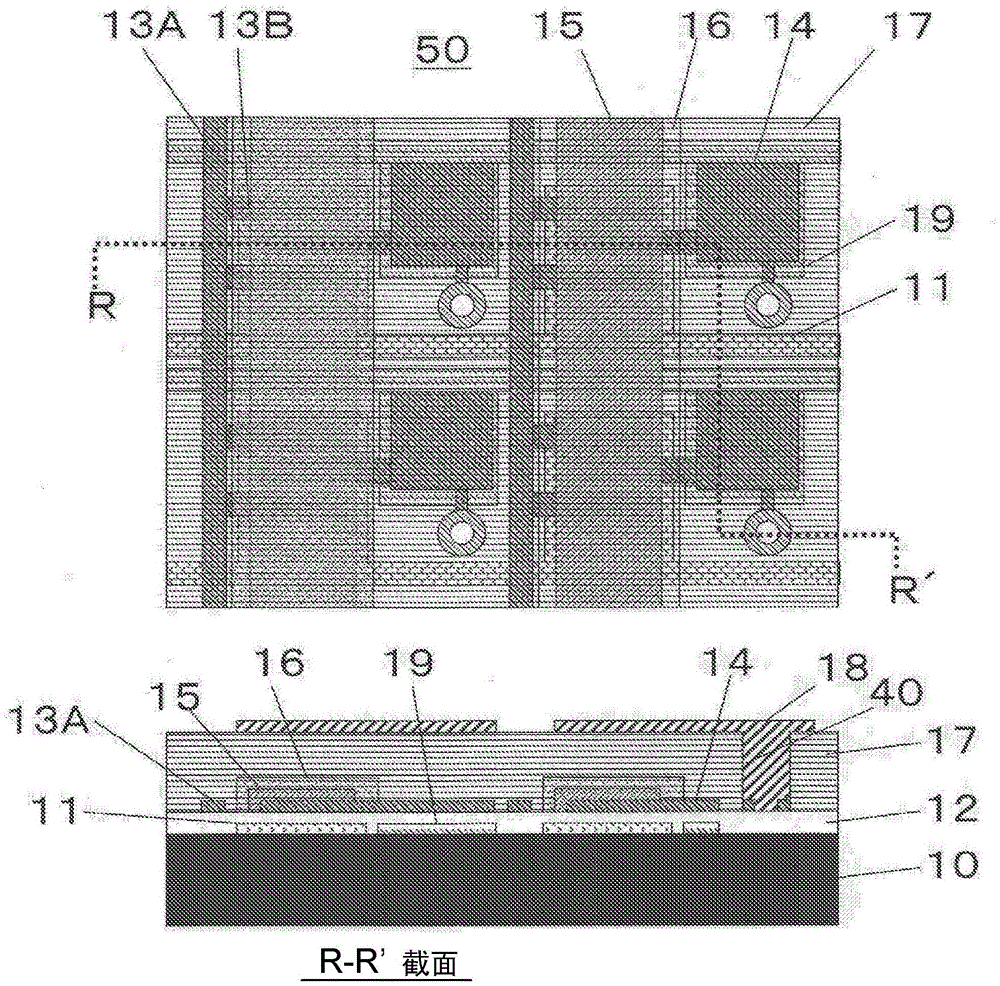

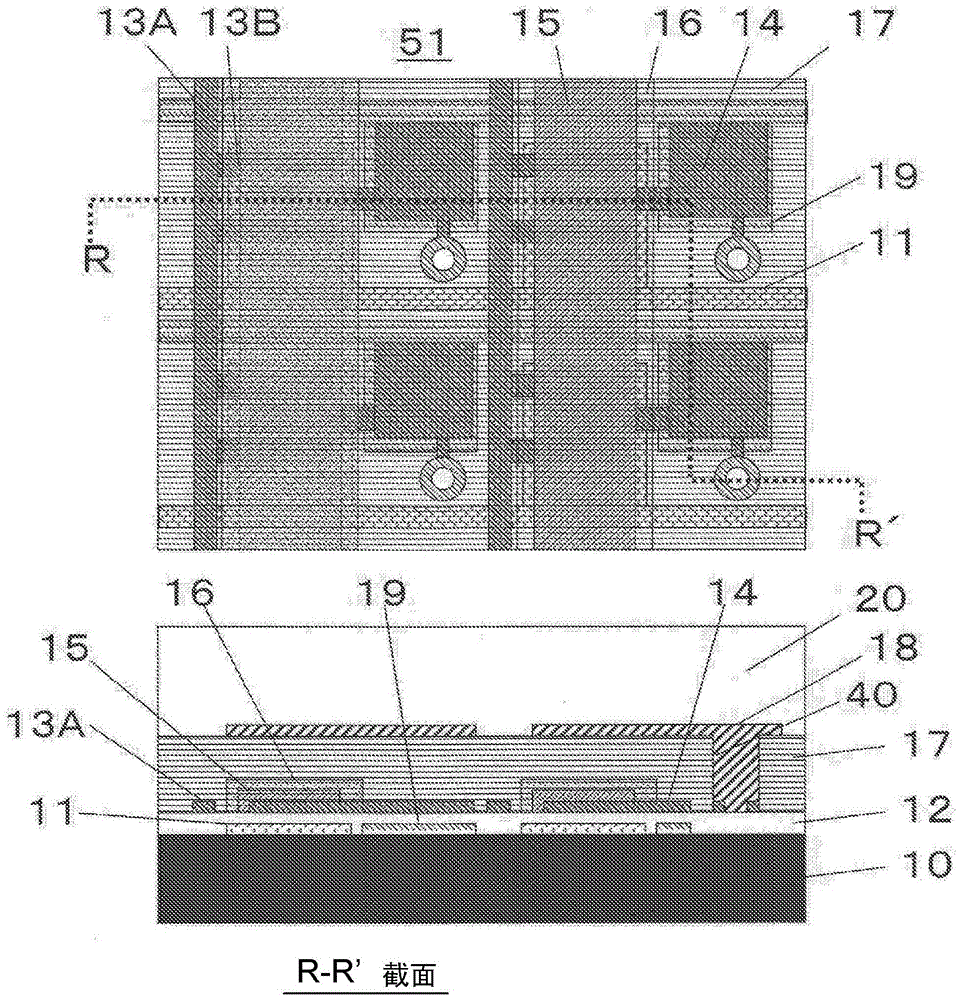

[0048] figure 2 A pattern layout plan view and a cross-sectional structure showing a schematic configuration of the thin film transistor array 51 composed of the bottom-gate bottom-contact type flexible thin film transistor array of the first embodiment are shown. Refer to the following figure 2 The manufacturing method will be described. The size of one element of the thin film transistor array 51 is 300 μm×300 μm, and there are 240×320 elements.

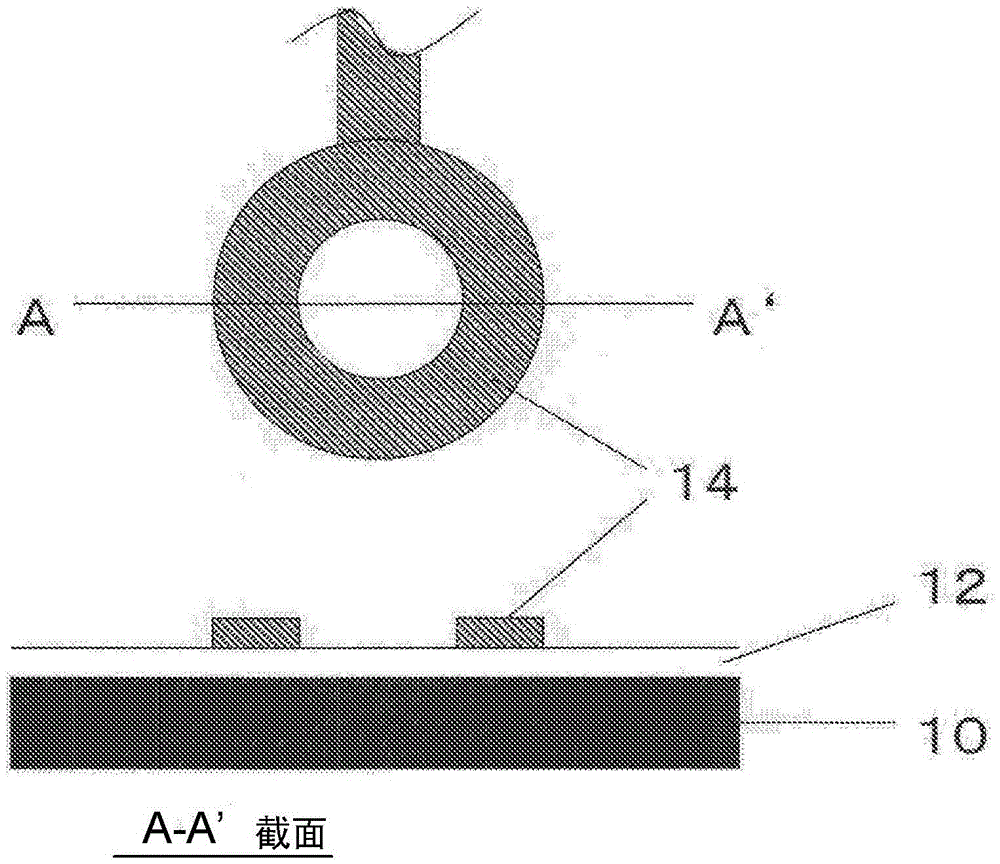

[0049] A polyethylene naphthalate (PEN) film was used as the plastic substrate 10 . After forming a film of 100 nm of aluminum on the PEN film by sputtering, photolithography and etching were performed using a positive resist, and then the resist was peeled off to form gate electrode 11 and capacitor electrode 19 .

[0050] Next, after coating a coating-type photosensitive insulating material (AH series, manufactured by Hitachi Chemical Co., Ltd.) as a gate insulating material by spin coating, the terminal portion of the gate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com