Dynamic tdd ul/dl configuration indication for tdd eimta in carrier aggregation

一种高强度螺栓、耐延迟断裂的技术,应用在螺钉、螺纹紧固件、拉伸载荷作所特别改进的连接件等方向,能够解决耐延迟断裂性降低、制造成本增大、耐延迟断裂性说不上充分等问题,达到耐延迟断裂性和螺栓成形性优异、螺栓成形性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] Below, the present invention is described in more detail by enumerating the examples, but the present invention is not limited by the following examples, and can also be modified and implemented within the scope of being able to meet the purpose of the foregoing and the following, and these are all included in the technology of the present invention. within range.

[0092] The steel grades A to F and A1 to T1 composed of the chemical composition shown in Table 1 below were hot rolled to Thereafter, quenching and tempering were performed under the conditions shown in Table 2 below. The conditions of hot rolling are as follows.

[0093] The reheating temperature of the billet: 1000-1200°C, the finish rolling temperature: 900-1100°C, and then cooling to 300°C at an average cooling rate of 0.05-10°C / sec.

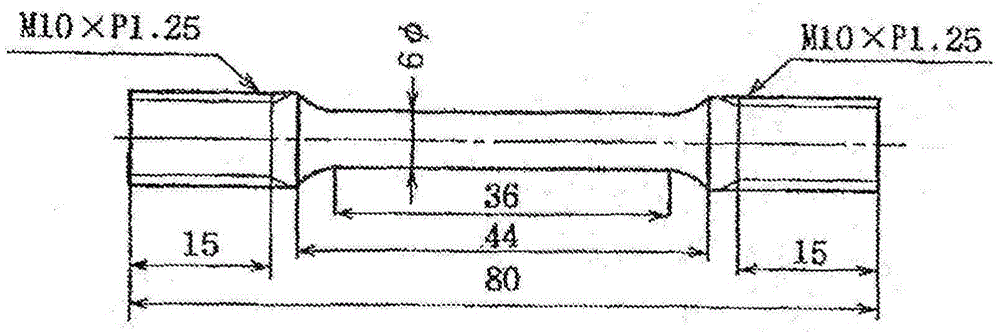

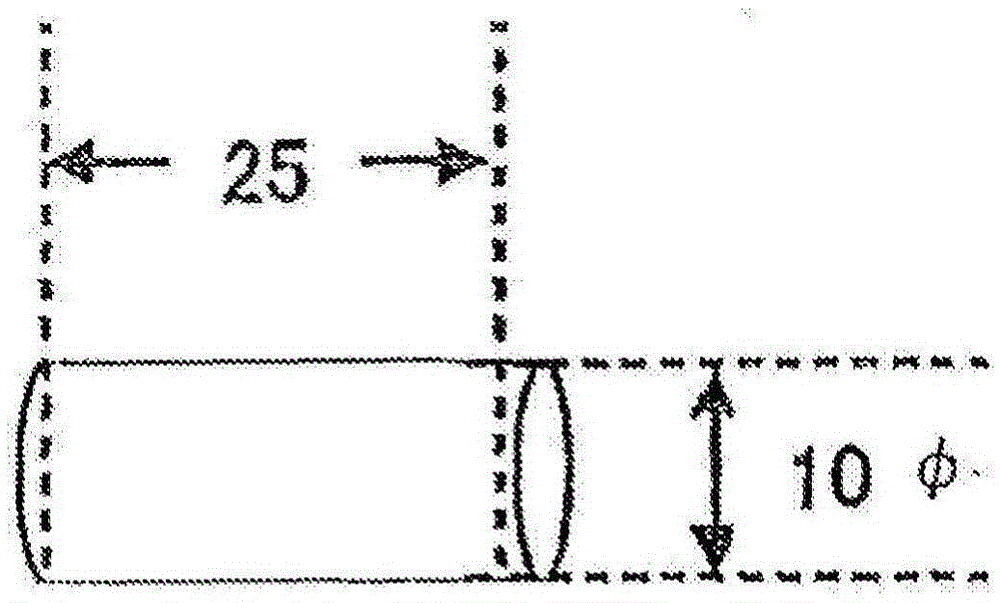

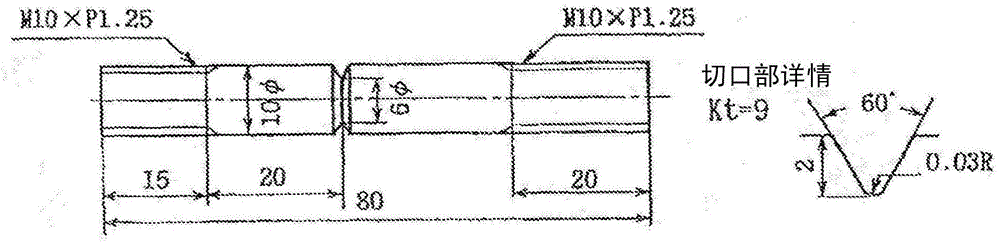

[0094] For each sample thus obtained, the prior austenite grain size number, tensile strength (TS), ductility (reduction of area), corrosion loss, delayed fracture str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com