Friction stir welding method for steel sheets and method of manufacturing joint

A joining method, friction stir technology, applied in manufacturing tools, welding/welding/cutting items, welding equipment, etc., can solve problems such as temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

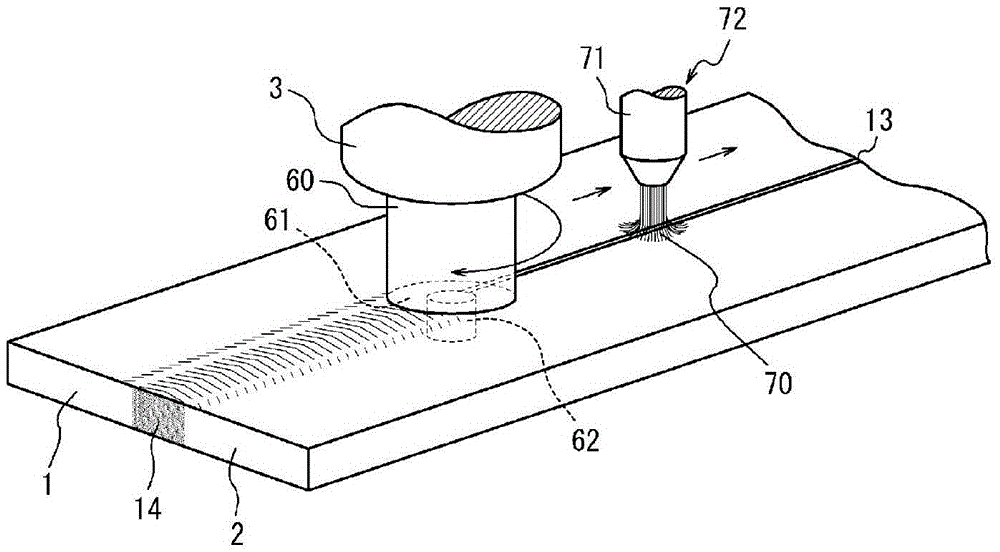

[0097] Figure 4 The friction stir welding apparatus used for practice of this invention is shown. In this device, the induction heating device 4 is arranged in front of the bonding tool 60 in the traveling direction, and the induction heating device 8 is arranged behind it, so that heating can be performed by these induction heating devices. The tool 60 has a shape having a protruding probe 62 made of tungsten carbide as a base material and a flat shoulder 61 . In addition, in order to suppress oxidation of the joint portion, the joint was performed while blowing argon gas from the front in the traveling direction of the tool 60 .

[0098] It should be noted that among the figures, symbol 9 is a cooling device, 35 is a power supply, and 40 is a heating temperature setting panel.

[0099] use Figure 4 The friction stir welding apparatus shown in , performs friction stir welding under the conditions shown in Table 1 on a steel plate (C: 0.3% by mass, Si: 0.1% by mass, Mn: 1...

Embodiment 2

[0106] Same as Example 1, use Figure 4 The friction stir welding apparatus shown in , performed friction stir welding under the conditions shown in Table 2. The joining conditions were almost the same as in the case of Example 1, but in this example, a liner material was used at the time of joining.

[0107] Table 2 shows the results of investigations on the availability of welding, joint efficiency, and stability of weld bead width when the above-mentioned friction stir welding was carried out. Regarding the bead width, the minimum bead width and the maximum bead width were measured, and it was stable if the difference was 20% or less of the minimum bead width.

[0108]

[0109] As shown in Table 2, when performing friction stir welding based on the present invention, even at a welding speed exceeding 0.5 m / min, a stable weld width can be obtained without welding defects and at high joint efficiency. Engagement joints.

Embodiment 3

[0111] Same as Example 1, use Figure 4 In the friction stir welding apparatus shown in , friction stir welding was performed under the conditions shown in Table 3. The bonding conditions are almost the same as those in the first embodiment, but in this third embodiment, the cooling device 9 and the rear heating device 8 are used to carry out the bonding.

[0112] Table 3 shows the joint efficiency of the above-mentioned friction stir welding and the standard deviation of the joint efficiency of 10 samples obtained under the same conditions.

[0113] Regarding the possibility of joining, ○ and ◎ indicate that it can be joined, and the ◎ mark indicates that the tool can be joined without damage, and there is no visible defect in the entire length of the joint and the weld width is stable; the ○ mark indicates that the tool can be joined without damage and the joint part There is no visible defect; the X mark indicates that the tool is damaged or there is a visible defect in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com