Thermal control system of a stationary micro fuel cell cogeneration device

A micro-fuel cell and cogeneration technology, applied in the direction of fuel cell heat exchange, fuel cell additives, etc., can solve the problems of time-consuming, fuel cell stack output power limited in the start-up time, etc., to save volume, shorten Heating time, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

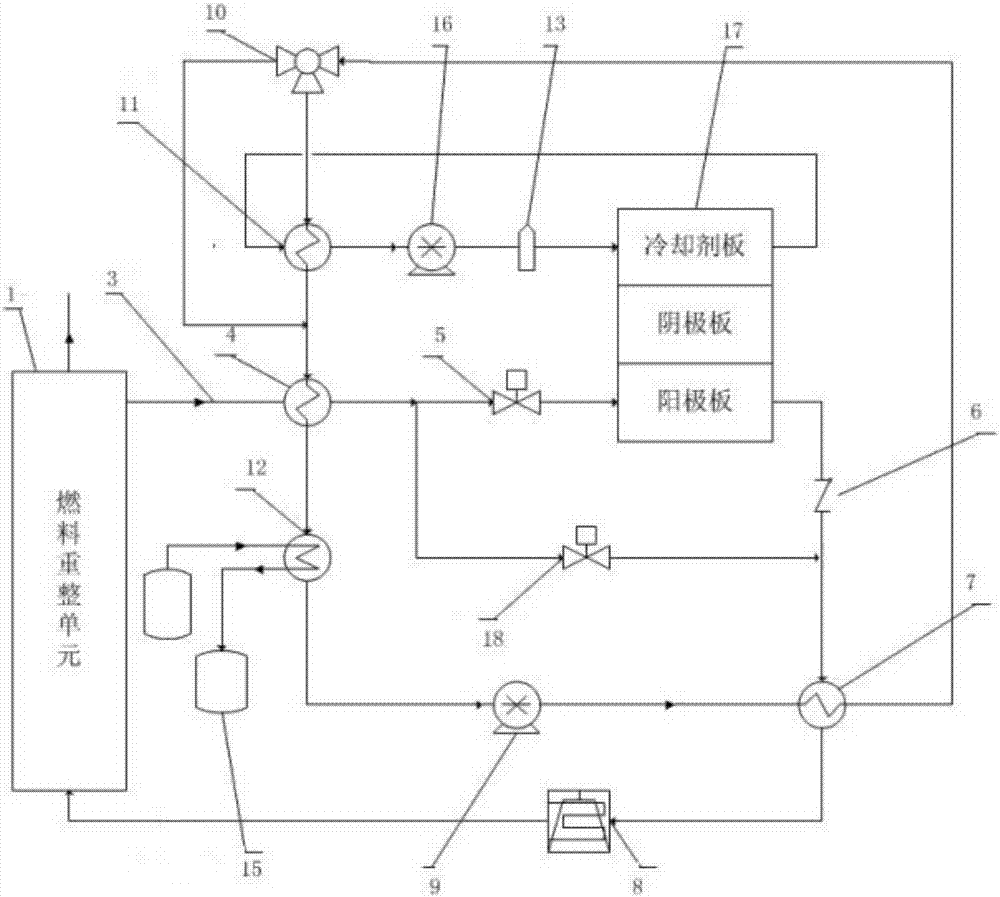

[0024] Such as figure 1As shown, a thermal control system for a residential micro-fuel cell cogeneration device, including a fuel reforming unit 1 for catalytically converting hydrocarbon fuel into hydrogen and a hydrothermal cycle unit connected to the fuel reforming unit 1 , it is characterized in that, the described hydrothermal cycle unit includes airflow pipeline, cooling water circulation loop and cooling liquid circulation loop, and the airflow pipeline includes airflow inlet pipeline 3, No. 1 heat exchanger 4, No. 1 solenoid valve 5, single Direction valve 6, No. 2 heat exchanger 7, condenser 8 and No. 2 solenoid valve 18, the air flow pipeline is divided into two, one is the gas path entering the fuel cell stack, and the other is a bypass, the fuel entering the The gas path of the battery stack is a normal working gas path, and the high-temperature hydrogen-rich mixed gas flow generated by the fuel reforming unit 1 enters the No. The outlet of No. 4 heat exchanger 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com