Diodes and methods of forming them

A diode and tooth-shaped technology, applied in the field of diodes and their formation, can solve the problem of excessive wafer area occupied by diodes, and achieve the effects of saving wafer area, increasing contact area, and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It can be seen from the background art that the diode in the prior art has the problem of too large area. Now combine the structure of the diode in the prior art to analyze the reason of its too large area:

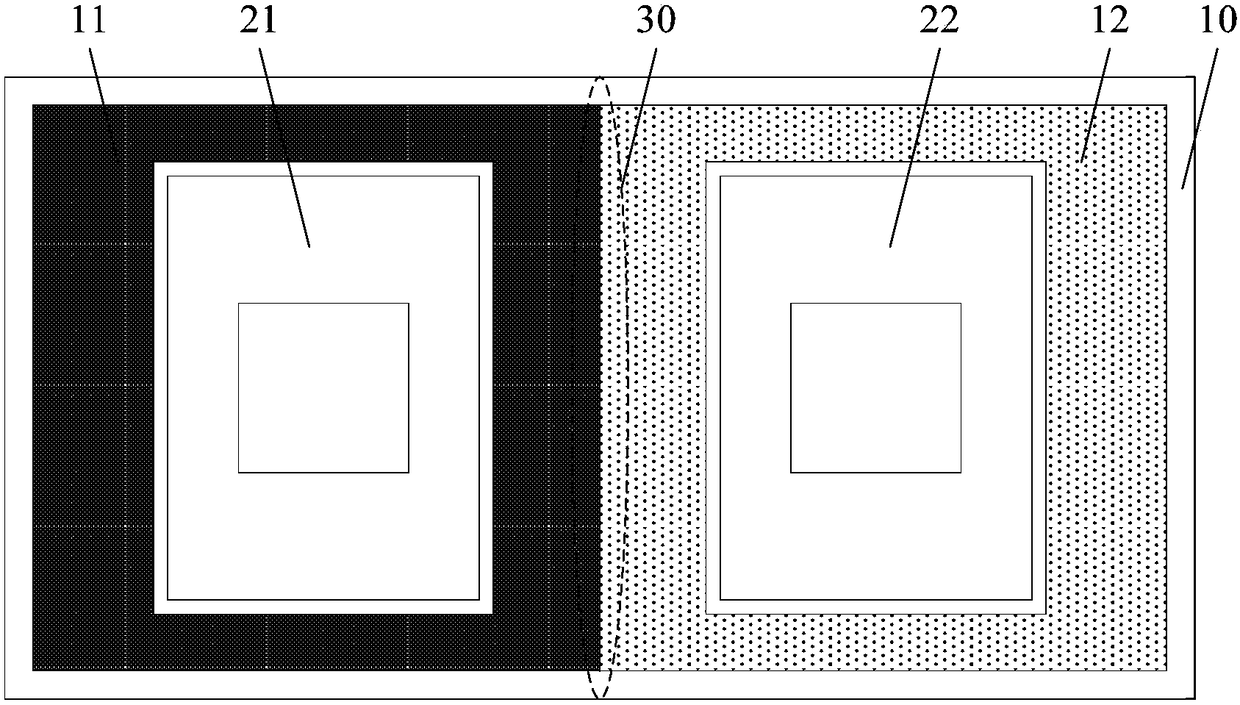

[0028] refer to figure 1 , shows a schematic diagram of a top view structure of a diode.

[0029] The diode includes a substrate 10; an N-type semiconductor layer 11 and a P-type semiconductor layer 12 adjacent to the surface of the substrate 10; The second connecting piece 22 .

[0030] The first connector 21 is connected to the metal wire (static receiving end), the second connecting member 22 is connected to the ground (static discharge end), and the potential of the metal wire is higher than the ground. Therefore, the PN junction formed by the N-type semiconductor layer 11 and the P-type semiconductor layer 12 is reverse-biased between the metal line and the ground, so the diode is in a cut-off state under normal operating conditions, and does not affect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com