An emergency release valve group

A valve group and pressure reducing valve technology, applied in servo motor components, fluid pressure actuating devices, servo motors, etc., can solve problems such as danger, motor cavitation, load drop, etc., to reduce energy consumption and weight , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

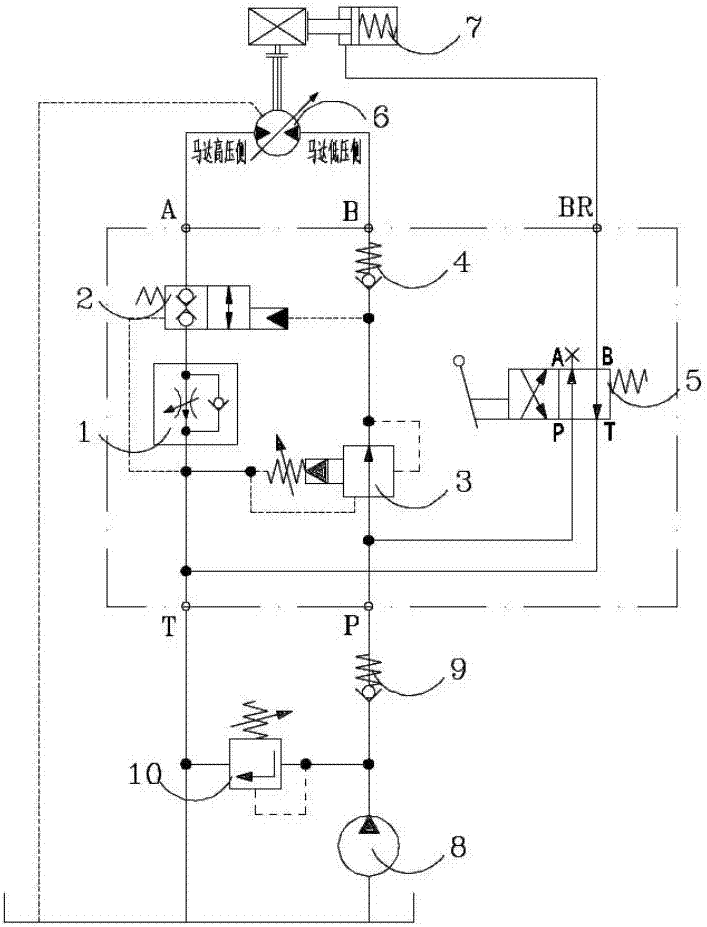

[0026] The above-mentioned features and advantages of the present invention can be better understood after reading the detailed description of the embodiments of the present disclosure in conjunction with the following drawings. In the drawings, components are not necessarily drawn to scale, and components with similar related properties or characteristics may have the same or similar reference numerals.

[0027] figure 1 The structure of the preferred embodiment of the emergency lowering valve group of the present invention is shown. See figure 1 In this embodiment, the motor-driven hoisting winch is taken as an example for illustration. The entire emergency lowering valve group includes a system for opening the brake and a system for realizing emergency lowering.

[0028] The emergency lowering valve group in this embodiment is externally connected to a motor 6 , a hydraulic brake 7 and an oil source. The oil source includes, for example, a pump 8 , a one-way valve 9 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com