A kind of preparation method and application of carbon quantum dot light stabilizer

A technology of carbon quantum dots and light stabilizers, which is applied in the field of preparing carbon quantum dot light stabilizers for paper by hydrothermal method, can solve the problems of poor light resistance, poor water solubility, low yield, etc., and achieves photo-induced yellowing of paper. The effect of suppressing and improving initial whiteness and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a carbon quantum dot light stabilizer.

[0030] 1. Preparation method

Embodiment 1

[0032] Step 1, weigh 1.26g of citric acid and dissolve it in 30mL of deionized water, stir and mix evenly at room temperature (10min) to obtain a precursor solution (citric acid concentration: 0.2mol / L).

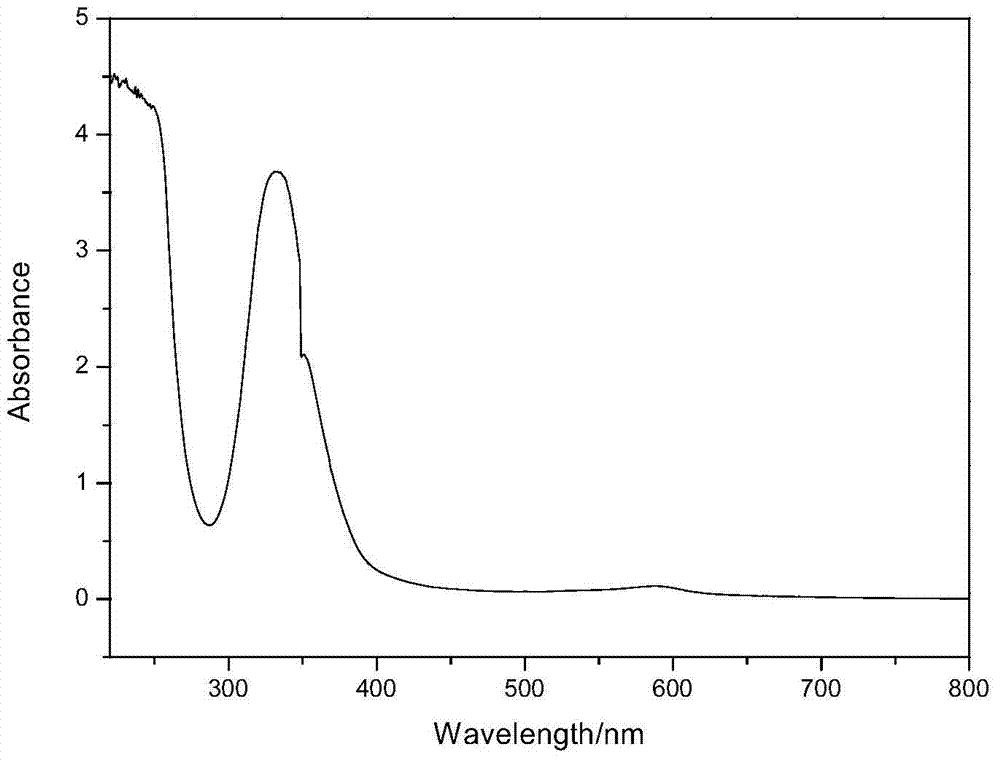

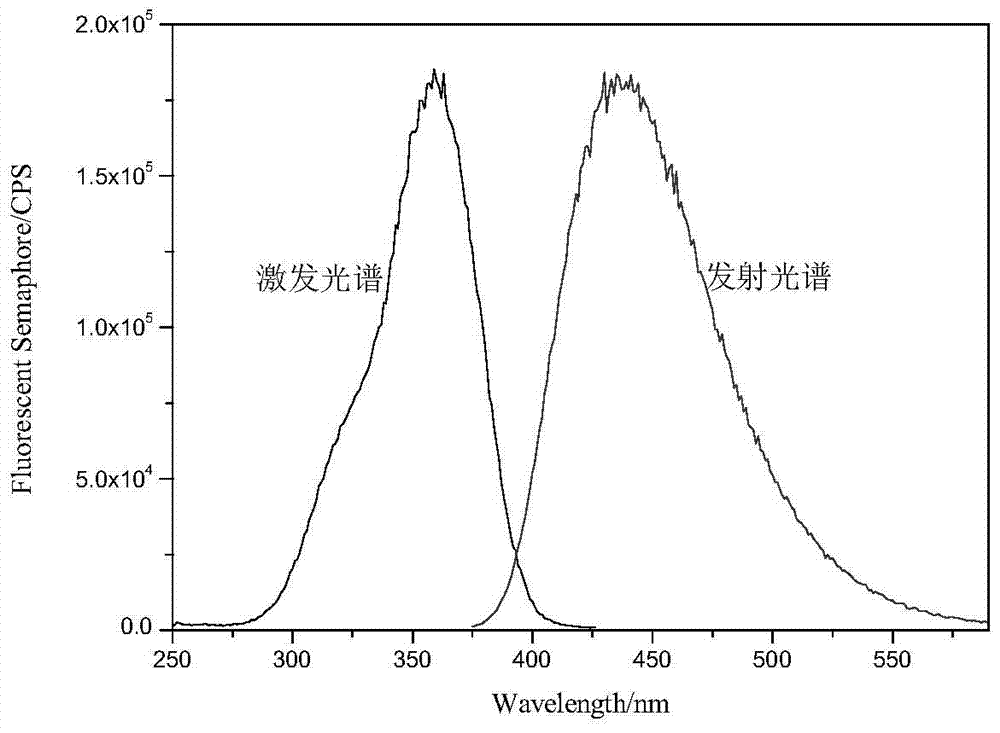

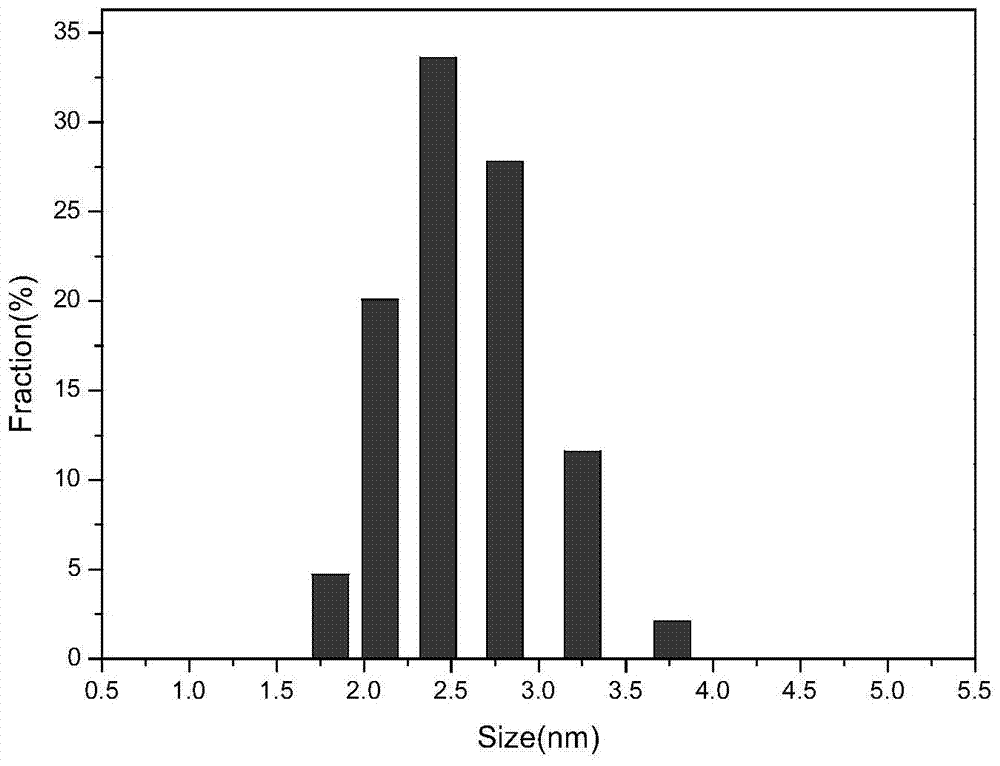

[0033] Step 2: Place the precursor solution in a p-polyphenylene-lined hydrothermal reactor, raise the temperature to 200°C in an oven, keep it warm for 5 hours, and then cool it naturally to room temperature to obtain a carbon quantum dot solution.

[0034] Step 3, 0.2g 2,2,6,6-tetramethylpiperidinamine was added to the carbon quantum dot solution, and magnetically stirred and mixed uniformly (10min) at room temperature to obtain solution A (2,2,6,6- The concentration of tetramethylpiperidinamine is 0.04mol / L).

[0035] Step 4: Place the solution A in a p-polyphenylene-lined hydrothermal reaction kettle, raise the temperature to 180°C in an oven, keep it warm for 1 hour, and then cool it naturally to room temperature to obtain a modified carbon quantum dot solution.

[003...

Embodiment 2

[0044] Step 1: Dissolve 0.55g of oxalic acid in 30mL of deionized water, stir and mix evenly (10min) at room temperature to obtain a precursor solution (oxalic acid concentration: 0.2mol / L).

[0045] Step 2: Place the precursor solution in a p-polyphenylene-lined hydrothermal reactor, raise the temperature to 220°C in an oven, keep it warm for 5 hours, and then cool it naturally to room temperature to obtain a carbon quantum dot solution.

[0046] Step 3, 0.2g 2,2,6,6-tetramethylpiperidinamine was added to the carbon quantum dot solution, and magnetically stirred and mixed uniformly (10min) at room temperature to obtain solution A (2,2,6,6- The concentration of tetramethylpiperidinamine is 0.04mol / L).

[0047] Step 4: Place the solution A in a p-polyphenylene-lined hydrothermal reaction kettle, raise the temperature to 180°C in an oven, keep it warm for 1 hour, and then cool it naturally to room temperature to obtain a modified carbon quantum dot solution.

[0048] Step 5, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com