Toughened heat resistant type environmentally-friendly efficient compound stabilizer and preparation technology

A composite stabilizer and a preparation process technology, applied in the field of composite stabilizers, can solve the problems that the performance of polyvinyl chloride cannot be well improved, the performance of the composite stabilizer is single, and it does not have impact tensile strength, etc. Cost, improved stability, and effect of suppressing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

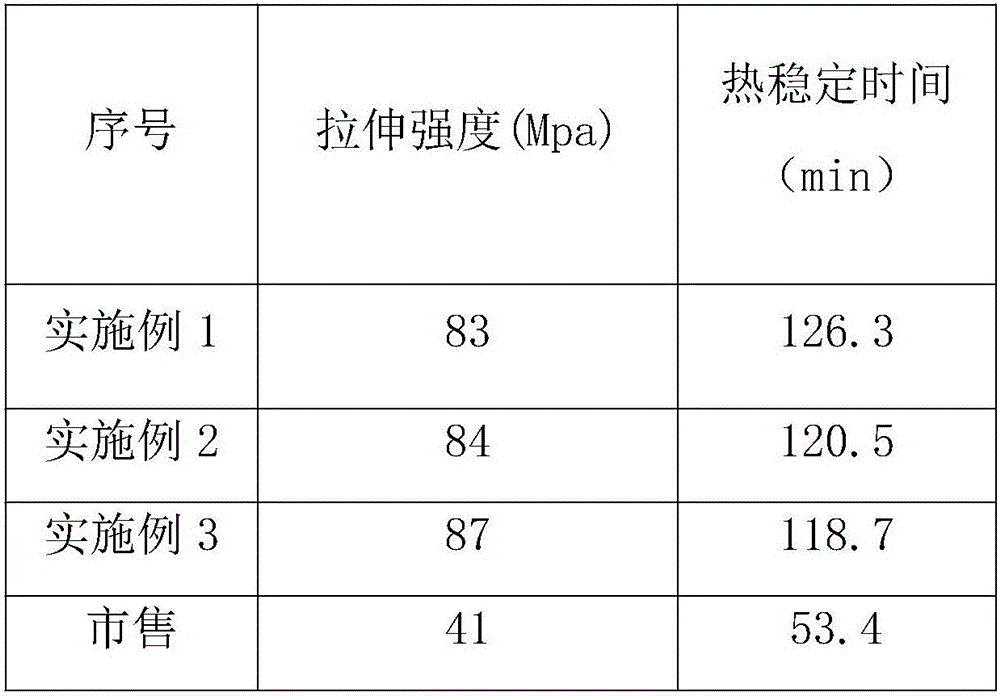

Examples

Embodiment 1

[0017] A toughening and heat-resistant environment-friendly high-efficiency composite stabilizer, comprising the following components by weight percentage: zinc stearate 35%, calcium stearate 10%, diphenylformylmethane 2%, polyol 5 %, 5% hydrotalcite, 5% phosphite, 11% zeolite, 2% antioxidant, 5% methyl methacrylate, 5% butadiene acrylonitrile gum, 15% Feto wax.

[0018] A preparation process of a toughened and heat-resistant environment-friendly and high-efficiency composite stabilizer, comprising the following steps:

[0019] (1) Zinc stearate, calcium stearate, diphenylformylmethane, polyhydric alcohol, hydrotalcite, phosphite, antioxidant are mixed in proportion;

[0020] (2) Add zeolite and Fischer-Tropsch wax and mix for 20min;

[0021] (3) Finally, add methyl methacrylate and butadiene acrylonitrile glue, and mix evenly to obtain a toughened and heat-resistant environmentally friendly and efficient composite stabilizer.

[0022] In this embodiment, in the step (1), zi...

Embodiment 2

[0026] A toughening and heat-resistant environment-friendly high-efficiency composite stabilizer, comprising the following components by weight percentage: zinc stearate 30%, calcium stearate 15%, diphenylformylmethane 3%, polyol 2 %, 8% hydrotalcite, 8% phosphite, 4% zeolite, 1% antioxidant, 8% methyl methacrylate, 8% butadiene acrylonitrile rubber, 13% feta wax.

[0027] A preparation process of a toughened and heat-resistant environment-friendly and high-efficiency composite stabilizer, comprising the following steps:

[0028] (1) Zinc stearate, calcium stearate, diphenylformylmethane, polyhydric alcohol, hydrotalcite, phosphite, antioxidant are mixed in proportion;

[0029] (2) Add zeolite and Fischer-Tropsch wax and mix for 20min;

[0030] (3) Finally, add methyl methacrylate and butadiene acrylonitrile glue, and mix evenly to obtain a toughened and heat-resistant environmentally friendly and efficient composite stabilizer.

[0031] In this embodiment, in the step (1), ...

Embodiment 3

[0035] A toughening and heat-resistant environment-friendly high-efficiency composite stabilizer, comprising the following components by weight percentage: zinc stearate 37%, calcium stearate 5%, diphenylformylmethane 1%, polyol 8 %, 2% hydrotalcite, 2% phosphite, 18% zeolite, 3% antioxidant, 2% methyl methacrylate, 2% butadiene acrylonitrile gum, 20% feta wax.

[0036] A preparation process of a toughened and heat-resistant environment-friendly and high-efficiency composite stabilizer, comprising the following steps:

[0037] (1) Zinc stearate, calcium stearate, diphenylformylmethane, polyhydric alcohol, hydrotalcite, phosphite, antioxidant are mixed in proportion;

[0038] (2) Add zeolite and Fischer-Tropsch wax and mix for 20min;

[0039] (3) Finally, add methyl methacrylate and butadiene acrylonitrile glue, and mix evenly to obtain a toughened and heat-resistant environmentally friendly and efficient composite stabilizer.

[0040] In this embodiment, in the step (1), zin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com