Processing device for one yarn with multiple colors

A color treatment and pretreatment technology, applied in the field of multi-color treatment devices, can solve the problems of color fastness and hue change of textiles without the method of direct yarn treatment, and achieve the advantages of improving color fastness and moisture absorption and perspiration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

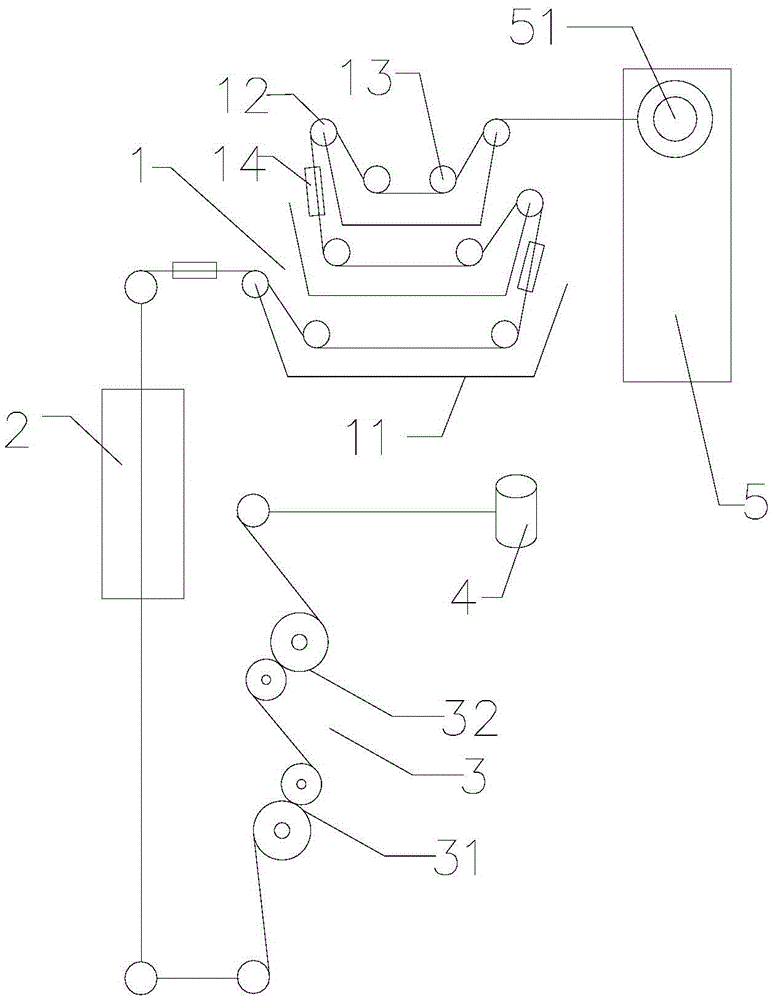

[0020] Please also refer to figure 1 , as shown in the figure, it can be seen that the multi-color processing device of the present invention includes a yarn feeding mechanism 5, a pretreatment mechanism 2, a drafting mechanism 3 and a take-up mechanism 4; the yarn feeding mechanism 5 includes a raw silk rack and a silk feeding roller 51, The feeding roller 51 realizes the wire rod transmission on the raw wire frame; the pretreatment mechanism 2 includes a deformation heating box and a cooling box, and the deformation heating box is used to heat the wire rod into a plasticized state and reduce tensile deformation stress, and the role of the cooling plate It is the fixation of the structure of the yarn before drafting; the drafting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com